[vc_row][vc_column][vc_column_text css=””]

Pure Tungsten Bar

Standards: ASTM B760, GB/T 4187

Purity: ≥99.95%, 99.999% is also available

Density: 18.3 g/cm3

Melting point: 3,410 ℃

Size: Custom dimensions. Diameter: 0.5 – 200 mm. Square shape is also available

Surface: Sintering surface, forged surface, ground surface, polished surface

Process: Powder metallurgy

Properties and Characteristics of Tungsten Bars

High Melting Point

Tungsten boasts the highest melting point of all elements, exceeding 3,400 degrees Celsius (6,152 degrees Fahrenheit). This extraordinary property makes tungsten bars ideal for applications that involve extreme temperatures, such as in high-temperature furnaces and aerospace components.

Superior Density

Tungsten has a high density, making tungsten bars exceptionally heavy and providing them with impressive mass. This property is crucial in applications where weight is a factor, such as in counterweights for aircraft and as balancing weights in various machinery.

Outstanding Thermal Conductivity

Tungsten bars exhibit excellent thermal conductivity, allowing them to efficiently transfer heat. This property is advantageous in applications where heat dissipation is critical, including electronic components and as part of high-performance heat sinks.

Remarkable Mechanical Strength

Tungsten is renowned for its exceptional mechanical strength and durability. Tungsten bars maintain their structural integrity even under extreme conditions, making them suitable for applications requiring robust materials, such as in the manufacturing of tools, dies, and high-temperature furnace elements.

Corrosion Resistance

Tungsten is highly resistant to corrosion, ensuring that tungsten bars remain unaffected by various chemical environments. This property enhances their longevity and reliability in corrosive settings, making them suitable for applications in the chemical and petrochemical industries.

Excellent Machinability

Tungsten bars exhibit good machinability despite their hardness. This characteristic allows for the precision machining of intricate components, making tungsten bars valuable in industries that demand high-precision parts, such as the aerospace and medical sectors.

Radioactive Shielding Properties

Due to its high density, tungsten is effective in absorbing and attenuating radiation. Tungsten bars find applications in the medical field, particularly in X-ray shielding and radiation therapy, where their density provides efficient protection against ionizing radiation.

Versatility in Alloys

Tungsten is often alloyed with other metals to enhance specific properties. Tungsten-Copper (W-Cu) Alloys, for example, Copper is renowned for its excellent thermal conductivity, while tungsten provides high strength. By combining these two elements in an alloy, tungsten-copper achieves a balance of thermal conductivity and mechanical strength.

Tungsten Bars in Various Industries

Vacuum Furnace Heating Elements

Tungsten’s resistance to high temperatures and its low vapor pressure in a vacuum make pure tungsten rods suitable for use as heating elements in vacuum furnaces. These heating elements maintain their structural integrity under extreme conditions, ensuring reliable performance.

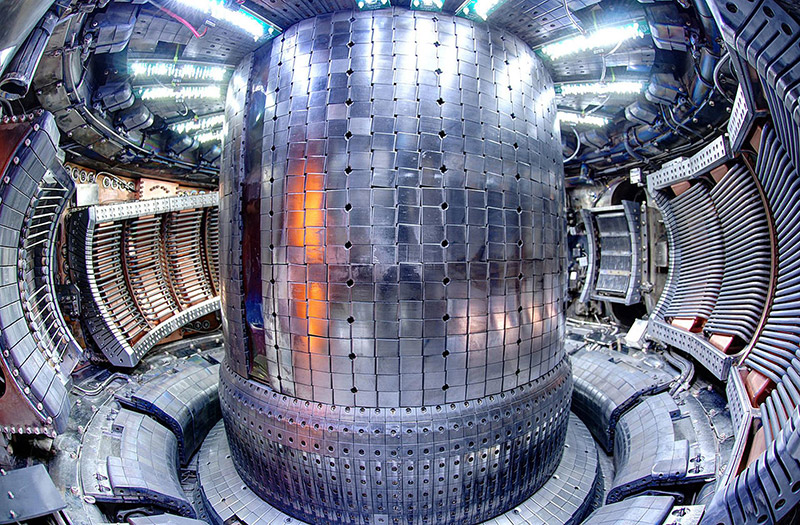

Nuclear Industry Components

Tungsten bars are used in various components within the nuclear industry, including radiation shields, reactor control bars, and other critical elements due to tungsten’s ability to withstand high radiation levels and extreme conditions.

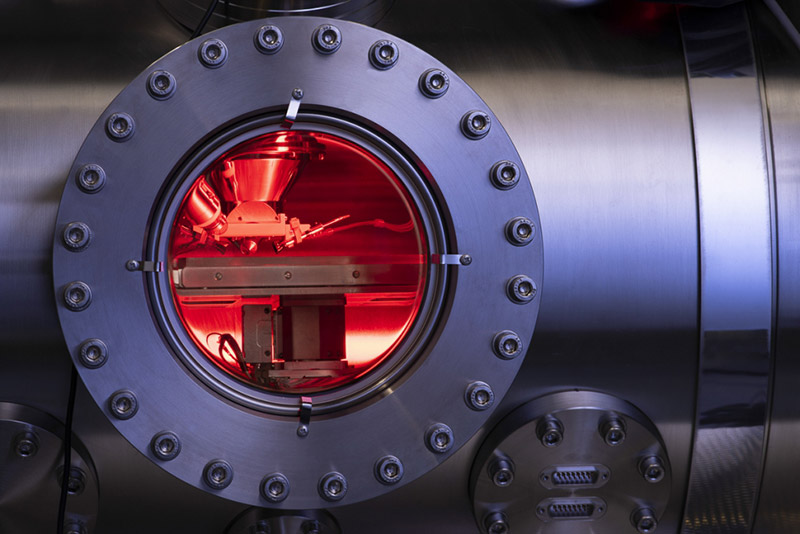

Electron Beam Machining

Tungsten bars are employed as cathodes in electron beam machining processes. The high melting point and electron emission characteristics of tungsten contribute to the precision and efficiency of this machining method.

Aerospace Propulsion Systems

In aerospace engineering, tungsten bars are used in components such as rocket nozzles and other propulsion systems. The high melting point and mechanical strength of tungsten make it well-suited for withstanding the extreme conditions associated with space travel.

Radiation Shielding

Tungsten bars, due to their high density, are utilized in radiation shielding applications. They are employed in medical facilities for shielding against X-rays and gamma rays, ensuring the safety of personnel and patients.

Ion Implantation

In semiconductor manufacturing, tungsten bars are used in ion implantation processes. The ability of tungsten to withstand high-energy ion bombardment makes it suitable for use as a target material in ion implanter.

Chemical Composition of Tungsten Bars

| W (≥%) | Chemical Content (≤ %) | |||||||||||||

| 99.95 | K | Fe | Al | Mo | Si | As | Ca | Cr | Mg | Mn | Na | Ni | Bi | Cd |

| 0.0015 | 0.003 | 0.003 | 0.003 | 0.0015 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.0005 | 0.0005 | |

| Cu | Pb | Sb | Co | Ti | Sn | |||||||||

| 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |||||||||

Tungsten V.S. Tungsten Alloy

| Pure Tungsten | Lanthanated-Tungsten Alloy | Tungsten Rhenium Alloy | |||||

| Composition | W | WLa10 (0.8-1.2% La2O3), WLa15 (1.3-1.7% La2O3), WLa20 (1.8-2.2% La2O3) | WRe3%, WRe5%, WRe25%, WRe26% | ||||

| Properties | High melting point. High density. Brittle. |

Enhanced ductility compared to pure tungsten. Improved electron emission characteristics. High-temperature stability. |

Improved ductility and tensile strength compared to pure tungsten. High-temperature strength and stability. Moderate electrical resistivity. |

||||

| Applications | TIG welding electrodes. High-temperature furnace components. Radiation shielding. |

Electron emitters in electron microscopy. Cathodes in electronics. High-temperature applications. |

Aerospace applications (thermocouples, rocket nozzles). High-temperature furnace elements. X-ray tubes |

||||

| Costs | Generally less expensive. | Moderate cost. | More expensive due to the addition of rhenium. | ||||

Summary

Pure Tungsten

Best for applications requiring the highest melting point and density.

Ideal when brittleness is not a limiting factor.

W-La Alloy

Offers improved ductility compared to pure tungsten.

Suitable for applications requiring enhanced electron emission.

Tungsten-Rhenium Alloy

Provides a balance of strength, ductility, and high-temperature stability.

Valuable in aerospace and high-temperature environments.

The choice depends on the specific requirements of the application, considering factors such as temperature conditions, mechanical properties, and cost considerations. Each material has its advantages, and the selection should be tailored to the needs of the particular use case.

Maintenance and Care Tips

Tungsten bars, given their unique properties and applications, require specific maintenance and care to ensure optimal performance and longevity. Here are some maintenance and care tips for tungsten bars:

-

Handling and Storage:

Handle with Care: Tungsten is a hard and brittle material. Avoid dropping or subjecting tungsten bars to impact, as this can lead to chipping or breakage. Avoid Contaminants: Keep tungsten bars away from contaminants, such as oils and greases, which can affect their performance.

-

Cleaning:

Use Mild Cleaning Agents: When cleaning tungsten bars, use mild cleaning agents and solvents. Harsh chemicals can react with tungsten and compromise its surface integrity.

Avoid Abrasives: Refrain from using abrasive materials for cleaning, as they can scratch or damage the surface.

-

Temperature Considerations:

Avoid Rapid Temperature Changes: Tungsten bars can withstand high temperatures, but rapid temperature changes, especially extreme quenching, may lead to thermal stress and potential cracking.

Gradual Cooling: Allow tungsten bars to cool gradually after exposure to high temperatures to minimize thermal shock.

-

Welding Applications:

Check for Contamination: In welding applications, ensure that the tungsten electbare is free from any contamination, which can affect the quality of the weld.

Proper Grinding Techniques: When grinding tungsten electbares for welding, use proper techniques and equipment to maintain the correct tip geometry.

-

Storage Conditions:

Dry Storage: Store tungsten bars in a dry environment to prevent corrosion or oxidation.

Avoid Humidity: If tungsten bars are exposed to high humidity, consider using moisture-absorbing materials in storage areas.

-

Avoid Excessive Force:

Minimize Bending: Tungsten bars are rigid but can be brittle. Avoid applying excessive force or bending, especially if the bar has a small diameter.

-

Use in Appropriate Applications:

Know the Limitations: Be aware of the limitations of tungsten bars. While they excel in high-temperature and high-strength applications, they may not be suitable for applications requiring high ductility.

-

Regular Inspection:

Check for Damage: Periodically inspect tungsten bars for any signs of damage, such as cracks or chips.

Replace Damaged Bars: If any damage is detected, replace the tungsten bar to prevent compromising the performance of the material.

-

Proper Machining Practices:

Use Suitable Tools: When machining tungsten bars, use tools that are designed for hard materials to avoid excessive wear and ensure precision.

[/vc_column_text][/vc_column][/vc_row]