[vc_row][vc_column][vc_column_text css=””]

Tungsten Wire

Tungsten wire is universally used to make tungsten wire resistance for bulbs, lamps. It can also be used to make optical instruments, electric vacuum components, and high-temperature resistant parts. Tungsten wire is characterized by the highest melting point and excellent electric conductivity. It has a high-performance in sintering and high-temperature in recrystallization. For the above features, it can serve a long life in many applications.

Type: Pure tungsten wire, WRe wire, gold-plated tungsten wire Diameter: 0.01 – 1 mm

Tungsten Alloy Wire For Photovoltaic Crystalline Silicon Cutting

Tungsten alloy wire for photovoltaic crystalline silicon cutting has greater development potential than traditional carbon steel busbars due to its high strength, good fatigue resistance, good conductivity, and high potential for thinning wires, and is gradually increasing market penetration.

| The Properties of Tungsten Alloy Wire For Photovoltaic Crystalline Silicon Cutting | ||

| Diameter (um) | Min. Tensile Strength (N/mm2) | Min. Breaking Force (N) |

| 48 ≤ d ≤ 50 | 5100 | 9.2 |

| 46 ≤ d ≤ 48 | 5300 | 8.8 |

| 43 ≤ d ≤ 46 | 5300 | 7.7 |

| 40 ≤ d ≤ 43 | 5500 | 6.9 |

| 37 ≤ d ≤ 40 | 5500 | 5.9 |

| 35 ≤ d ≤ 37 | 5500 | 5.3 |

| 33 ≤ d ≤ 35 | 5700 | 4.9 |

| 31 ≤ d ≤ 33 | 5700 | 4.3 |

Cut-resistant Tungsten Wire

Tungsten wire can be processed into extremely fine specifications. Compared with stainless steel of similar specifications, the strength and hardness are greatly improved. It is used to make cut-resistant protective gloves, which can make the gloves lighter, thinner and softer while meeting the same level of cut-resistant performance.

Tungsten gloves can effectively reduce skin irritation, make them more comfortable and flexible to wear, and are suitable for a variety of hand protection occasions. Through excellent design, it is expected to increase the cut resistance level of gloves by more than 2 levels.

| Performance Comparison of Tungsten Wire, Stainless Steel Wire And PE | |||||

| Items | Tungsten Wire | Stainless Steel Wire | PE | ||

| Universal | High Strength Type | ||||

| Diameter | 13 – 35 um | 20 – 35 um | 33 – 50 um | 10 – 30 um | |

| Tensile Strength | 3600 – 4000 N/mm2 | 4800 – 6000 N/mm2 | 1000 N/mm2 | 1000 – 1500 N/mm2 | |

| Density | 19.3 g/cm3 | 19.3 g/cm3 | 7.85 g/cm3 | 0.91 g/cm3 | |

| Vickers Hardness | 800 – 850 HV | 950 – 1000 HV | ≤ 210 HV | 50 – 70 HV | |

| Pulling Force | 1% – 3% | 1% – 3% | 40% – 60% | 10% – 50% | |

| Cut Resistance (A1-A9) | A5 – A9 | A5 – A9 | A3 – A4 | A2 – A3 | |

| Flexibility (1-10) | 9 | 8 | 5 | 10 | |

Tungsten Wire in Electronics

-

Tungsten Wire in Electronics

Tungsten wire is widely used as filaments in incandescent light bulbs. The high melting point of tungsten allows it to withstand the intense heat generated during illumination.

-

Electronic Components

Tungsten wire is employed in various electronic components, including connectors and electrodes. Its excellent electrical conductivity makes it valuable in ensuring efficient performance in electronic devices.

-

Microelectronics and Semiconductors

In the field of microelectronics, tungsten wire is utilized to create conductive paths in semiconductor devices. Its stability and conductivity contribute to the reliability of intricate electronic circuits.

-

Vacuum Tubes

Tungsten wire is used as heating elements in vacuum tubes. Its stability in high-temperature, low-pressure environments is crucial for efficient and controlled heat generation in electronic applications.

-

High-Frequency Applications

Tungsten wire, due to its high melting point and conductivity, is suitable for high-frequency applications such as radiofrequency (RF) antennas and components.

Gold-Plated Tungsten Wire

The most popular and legitimate application for gold-plated tungsten is as a corona discharge wire used to produce controlled electrical discharges in filtration and printing, as well as a variety of other processes.

In addition to its use in air ionizers and in printing/photocopying, other interesting commercial and industrial applications of corona discharge include the following:

-

Removal of unwanted electric charges from aircraft surfaces

-

Manufacture of ozone for oxidation use

-

Sanitization of pool water

-

Scrubbing of particles from air conditioning systems

-

Removal of unwanted volatile organics (such as pesticides, solvents, or chemical weapons) from the atmosphere

-

Surface treatment of polymer films for use with adhesives or printing inks

-

Production of photons for Kirlian photography film exposure

-

Electrohydrodynamic (EHD) thrusters, lifters, and other ionic wind devices

-

Nitrogen laser

-

Surface treatment for tissue culture (polystyrene)

-

Ionization of samples for mass spectrometry or ion mobility spectrometry

-

Solid-state cooling components for computer chips

The Data of Gold-Plated Tungsten Wire

| Diameter | 0.02 – 0.2 mm |

| Tensile Strength | 56g/mg/200mm |

| Gold-Plated Layer | ≥99.99% |

| Tungsten Content in The Core | ≥99.92% |

| Thickness of The Gold-Plated Layer | 0.3 um ± 10% |

| Corrosion Resistance | Soaked in concentrated nitric acid for 0.5 h at 80℃ |

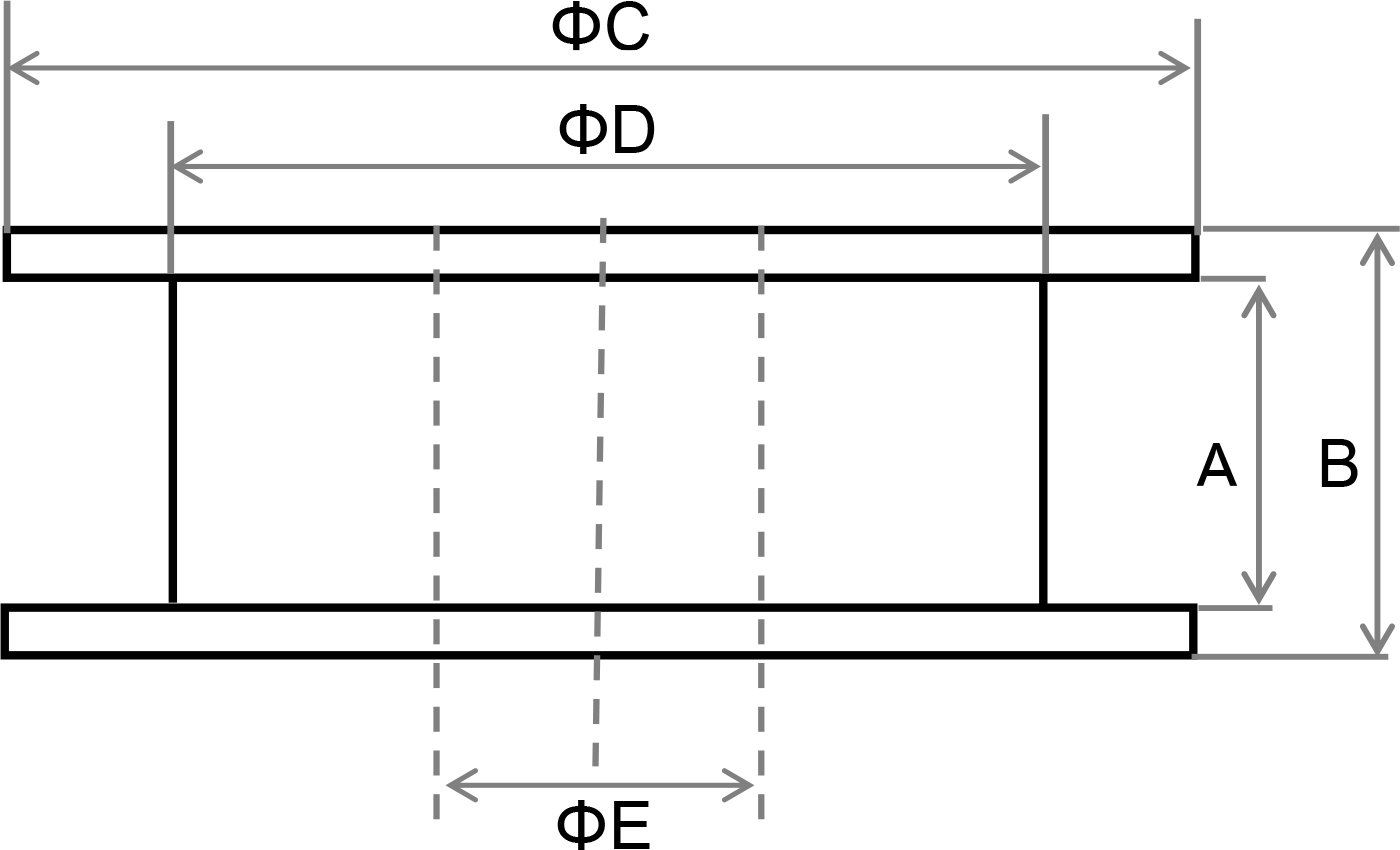

The Spools of Tungsten Wire

| A | B | C | D | E | |

| 301# | 91 | 102 | 300 | 212 | 52 |

| 302# | 85 | 93 | 300 | 180 | 52 |

| 280# | 43 | 57 | 280 | 226 | 216 |

| 266# | 31 | 40 | 268 | 226 | 216 |

| 220# | 155 | 185 | 220 | 110 | 40 |

| 125# | 100 | 125 | 125 | 80 | 16 |

| 124# | 21 | 28 | 124 | 103 | 97 |

| 120# | 25 | 35 | 120 | 90 | 10 |

| 119# | 15 | 22 | 120 | 80 | 10 |

| 118# | 20 | 28 | 118 | 102 | 95 |

| 110# | 20 | 28 | 110 | 90 | 10 |

| 106# | 26 | 34 | 106 | 75 | 14 |

| 100# | 80 | 100 | 100 | 63 | 16 |

| 58# | 6 | 10 | 61 | 39 | 6.8 |

| 61# | 28 | 25 | 60 | 44 | 14 |

| 60# | 20 | 28 | 60 | 40 | 10 |

[/vc_column_text][/vc_column][/vc_row]