[vc_row][vc_column width=”2/3″][vc_column_text css=””]Our Tantalum Niobium Alloy: Reliable and Durable

Our tantalum niobium alloy is engineered for exceptional strength and heat resistance, ideal for demanding applications. We prioritize high quality and tailor our alloys to meet your specific needs, ensuring reliability and longevity. We use advanced manufacturing techniques to ensure consistent, high-quality production of our alloy. This includes precision engineering and stringent quality checks.

By choosing our product, you’re opting for a solution that delivers performance and durability. Beyond our commitment to product excellence, we pride ourselves on our customer support and service. When you choose our alloy, you gain access to our expert team, ready to assist with technical guidance and responsive support.

Get A Fast Quote[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Product Specifications: ARS Metal’s Tantalum Niobium Alloy

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Product Specifications: ARS Metal’s Tantalum Niobium Alloy

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]Formula: TaNb

Purity: ≥99.9% or ≥99.95%

Grade: Ta-Nb3, Ta-Nb20, Ta-Nb30, Ta-Nb40

Appearance: Typically metallic grey in color, various forms (plate/sheet, bar, rod, tube, foil, wire, sputtering target)

Melting Point: N/A

Boiling Point: N/A[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Our Tantalum Niobium Alloy Range

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Our Tantalum Niobium Alloy Range

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Tantalum Niobium Foil

Materials: Ta-3Nb, Ta-20Nb, Ta-30Nb, Ta-40Nb

Standard: ASTM B708-98

Thickness: 0.03-0.07 mm

Width: 30-200 mm

Length: >50 mm

Tantalum Niobium Sheet & Plate

Materials: Ta-3Nb, Ta-20Nb, Ta-30Nb, Ta-40Nb

Standard: ASTM B708-98

Thickness: 0.07-20 mm

Width: 30-1000 mm

Length: 30-3000 mm

Tantalum Niobium Tube

Materials: Ta-3Nb, Ta-20Nb, Ta-30Nb, Ta-40Nb

Standard: ASTM B521-98

Outer diameter: 2-120 mm

Wall thickness: 0.5-5 mm

Length: 200-3000 mm

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Tantalum Niobium Alloy Rod & Bar

Grade: TNb-W-Ta TNb-W-Mo-Zr TTa-W TNb-W TTa-Nb TNb-Zr

| Grade | TNb-W-Ta | TNb-W-Mo-Zr | TTa-W | TNb-W | TTa-Nb | TNb-Zr | |

|---|---|---|---|---|---|---|---|

| Impurity Content , %,Max |

C | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| O | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| N | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| Application | For cast ingot and super alloys | ||||||

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Tantalum-Niobium Alloy Wire

| Grade | Chemical Compositions,Max | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | N | H | Nb | Fe | Ti | W | Mo | Si | Ni | Ta | |

| TaNb-1 | 0.01 | 0.02 | 0.01 | 0.0015 | 3-50 | 0.01 | 0.01 | 0.05 | 0.02 | 0.005 | 0.01 | Balance |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Niobium Alloy Applications

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”3/4″][vc_empty_space][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”3/4″][vc_empty_space][vc_column_text css=””]

1. Aerospace and Aviation

The alloy’s resistance to high temperatures and corrosion makes it suitable for jet engines and other aerospace components.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”3/4″][vc_empty_space][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”3/4″][vc_empty_space][vc_column_text css=””]

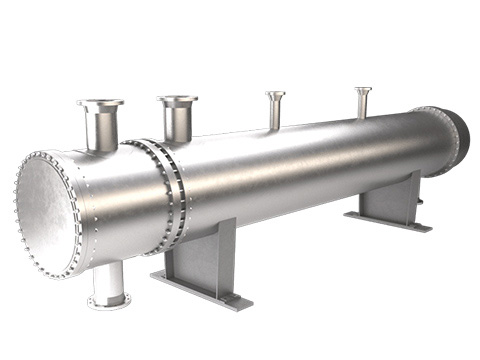

2. Chemical instruments

In chemical processing, the alloy’s corrosion resistance is vital. It is great for making heat exchangers and heating parts in chemical tools[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”3/4″][vc_empty_space][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”3/4″][vc_empty_space][vc_column_text css=””]

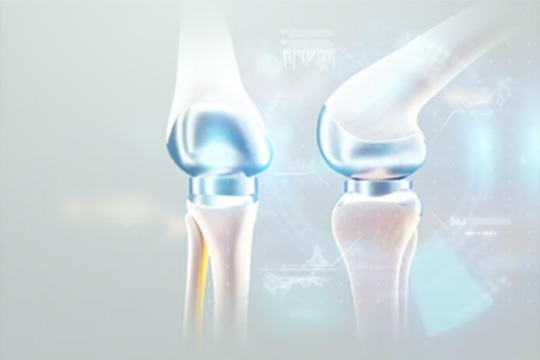

3. Medical Devices

The alloy is also used in medical devices. Its biocompatibility makes it safe for implants and surgical instruments.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”3/4″][vc_empty_space][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”3/4″][vc_empty_space][vc_column_text css=””]

4. Heat Insulation and Vacuum Furnaces

Tantalum niobium alloy handles very high temperatures well. This makes it great for making heating parts, insulation, and containers in vacuum furnaces.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

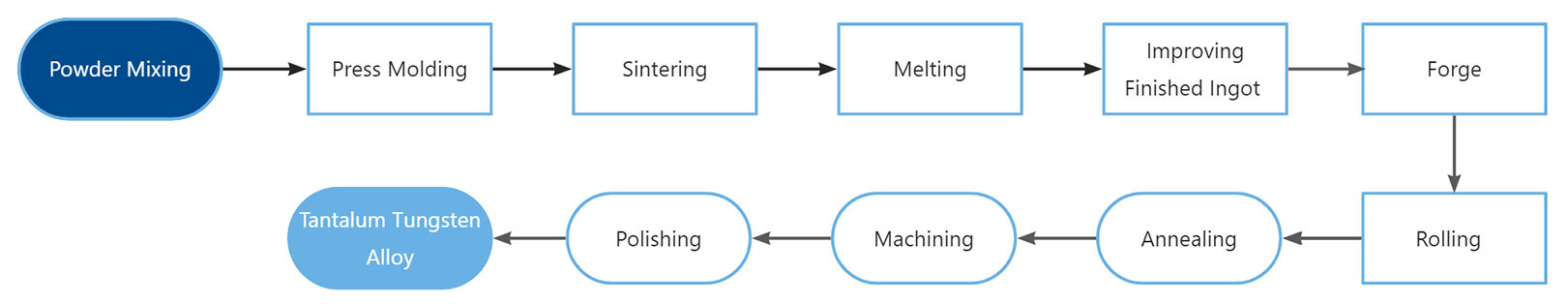

1. Powder Mixing

Mix ultra-fine tantalum powder and tungsten powder in the required proportions, then blend the mixture evenly in a drum-type mixer to obtain a uniform mixed powder.

2. Press Molding

Load the fine powder into the mold and press it into shape.

3. Sintering

Place the alloy rods in a vacuum sintering furnace, apply vacuum heating to sinter and obtain rough ingot blanks.

4. Melting

Melt the rough ingots multiple times using a vacuum electron beam furnace or vacuum arc furnace to produce alloy ingots.

5. Improving Finished Ingot Properties

Place the alloy ingot blanks in a high-frequency furnace, heat and forge multiple times, and process the surface oxide layer to produce finished ingots.

6. Forge

Cut and forge the billet according to the size and weight of the profile.

7. Rolling & Annealing

Repeatedly roll or forge, followed by multiple vacuum annealings to obtain rods or plates.

8. Machining and Polishing

Finally, through machining and polishing, achieve high-performance tantalum-tungsten alloy finished plates and rods.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Tantalum Tungsten Alloy: A Comprehensive Guide for Buyer

What is Tantalum Tungsten Alloy? A Brief Overview

Tantalum-tungsten alloy is a tough and long-lasting material made by mixing tantalum and tungsten. Tantalum makes it flexible and resistant to rust, while tungsten makes it very strong and able to withstand high temperatures.

This alloy is often used in making parts for airplanes, chemical tools, and medical devices because it can handle tough conditions like high heat and wear. It’s great for jobs where you need something that lasts a long time and doesn’t break down easily. Its unique properties make it ideal for harsh environments and demanding applications.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Unique Properties of Tantalum Tungsten Alloy

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

High Density and Hardness:

The alloy’s significant density and hardness make it resistant to wear and tear, contributing to its long service life.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Outstanding Corrosion Resistance:

It exhibits superior resistance to corrosion, even in aggressive chemical environments, ensuring longevity and durability.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Exceptional Melting Point:

The alloy maintains structural integrity under extreme temperatures, making it suitable for high-heat applications.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

Ductility:

Despite its strength, the alloy remains ductile (flexible), a quality contributed by tantalum.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Efficient Thermal Conductivity:

This property is critical for applications requiring efficient heat dissipation.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Stable Electrical Characteristics:

The alloy’s consistent electrical properties make it highly reliable for use in electronic applications.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

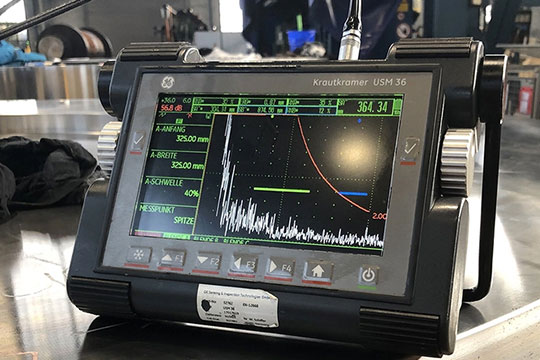

Quality Control: Tantalum Tungsten Alloy Testing

Making sure tantalum tungsten alloy is of top quality is very important because it’s used for important jobs in many industries. Quality checks and tests are a big part of making the alloy. Let’s look at the main ways we test and control the quality of tantalum alloy:

Visual Inspection:

Surface Check: Each product is visually inspected for any surface imperfections such as scratches, pits, or irregularities. Dimensional Accuracy: The thickness, width, and length of the alloy are measured to ensure they meet specified tolerances.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Chemical Analysis:

Purity Testing: To confirm the chemical composition and purity of the tantalum, tests like X-ray fluorescence (XRF) and inductively coupled plasma (ICP) are conducted. Trace Elements Analysis: Identifying trace elements is crucial to ensure the alloy’s suitability for sensitive applications, especially in electronics and medical fields.

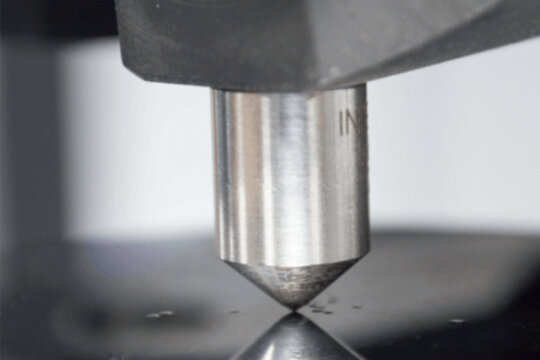

Mechanical Property Testing:

Tensile Strength Test: Determines the alloy’s strength by measuring its resistance to breaking under tension. Elongation Measurement: Assesses the ductility of the alloy, or how much it can stretch before breaking.

Non-Destructive Testing (NDT):

Ultrasonic Testing: Ultrasonic waves are used to detect internal flaws or inhomogeneities. Radiographic Testing: X-rays or gamma rays are used to inspect the internal structure of the tubes, identifying any internal defects.

Corrosion Resistance Testing:

The product is exposed to various corrosive agents to ensure its resistance, a key property for its use in chemical processing and medical devices.

Thickness Measurement:

Using micrometers or other precise instruments, the exact thickness of the product is verified, as it is a critical factor in many applications.

Certification and Documentation:

After passing all tests, the product is certified. A report is provided to the buyer detailing the tests conducted and their results, ensuring traceability and quality assurance.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Non-Destructive Testing (NDT)

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Composition of Tantalum Niobium Alloy

| Description | Mainly Content (%) | Impurities (%, Maximum) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ta | Nb | Fe | Si | Ni | W | Mo | Ti | O | C | H | N | |

| TaNb3 | Reminder | 2.5~3.5 | 0.005 | 0.005 | 0.004 | 0.005 | 0.005 | 0.004 | 0.012 | 0.005 | 0.0015 | 0.005 |

| TaNb20 | Reminder | 17.0~23 | 0.005 | 0.005 | 0.004 | 0.005 | 0.005 | 0.004 | 0.012 | 0.005 | 0.0015 | 0.005 |

| TaNb30 | Reminder | 27.0~33 | 0.005 | 0.004 | 0.003 | 0.004 | 0.004 | 0.003 | 0.012 | 0.004 | 0.0015 | 0.004 |

| TaNb40 | Reminder | 37.0~43 | 0.005 | 0.004 | 0.003 | 0.004 | 0.004 | 0.003 | 0.012 | 0.004 | 0.001 | |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Tantalum Niobium Alloy List

Tantalum Niobium Foil

Materials: Ta-3Nb, Ta-20Nb, Ta-30Nb, Ta-40Nb

Standard: ASTM B708-98

Thickness: 0.03-0.07 mm

Width: 30-200 mm

Length: >50 mm

Tantalum Niobium Sheet & Plate

Materials: Ta-3Nb, Ta-20Nb, Ta-30Nb, Ta-40Nb

Standard: ASTM B708-98

Thickness: 0.07-20 mm

Width: 30-1000 mm

Length: 30-3000 mm

Tantalum Niobium Alloy Rod & Bar

Grade: TNb-W-Ta TNb-W-Mo-Zr TTa-W TNb-W TTa-Nb TNb-Zr

| Grade | TNb-W-Ta | TNb-W-Mo-Zr | TTa-W | TNb-W | TTa-Nb | TNb-Zr | |

|---|---|---|---|---|---|---|---|

| Impurity Content , %,Max |

C | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| O | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | |

| N | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | |

| Application | For cast ingot and super alloys | ||||||

Remarks: Add element ratios can be added as required by the users’ special requirements to be agreed upon by the supplier and buyer.

Tantalum Niobium Tube

Materials: Ta-3Nb, Ta-20Nb, Ta-30Nb, Ta-40Nb

Standard: ASTM B521-98

Outer diameter: 2-120 mm

Wall thickness: 0.5-5 mm

Length: 200-3000 mm

Tantalum-Niobium Alloy Wire

Chemical Composition

Sizes/Tolerance(mm.max)

Φ(0.2-2.0mm)±0.01mm;Φ(2.0-3.0mm)±0.02mm

| Grade | Chemical Compositions,Max | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | N | H | Nb | Fe | Ti | W | Mo | Si | Ni | Ta | |

| TaNb-1 | 0.01 | 0.02 | 0.01 | 0.0015 | 3-50 | 0.01 | 0.01 | 0.05 | 0.02 | 0.005 | 0.01 | Balance |

Special requirements to be agreed upon by the supplier and buyer

Tantalum & Niobium Heating Elements

Applications: For heating elements in high-temperature vacuum furnaces

Tantalum & Niobium Heat Insulation Shields

Applications: For the insulation shields in high-temperature vacuum furnaces

Tantalum & Niobium Crucibles

Applications: For rare-earth metallurgy, load plates for anodes of tantalum and niobium, and insulation and niobium electrolytic capacitors sintered at high-temperatures, and corrosion-resistant containers in chemical industries.

Other Tantalum Niobium Products

Ta-Nb alloy is available in sheet and rod form in basically the same size range as tantalum. AEM is experienced in the production of Ta-Nb alloy products. Please feel free to contact us if you are interested in our Ta-Nb alloy products.[/vc_column_text][/vc_column][/vc_row]