[vc_row][vc_column width=”2/3″][vc_column_text]

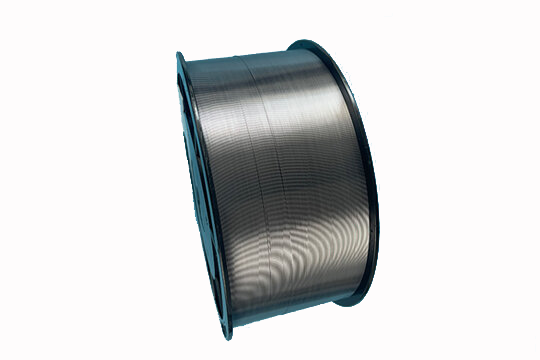

High-Performance Tantalum Wire: The Choice for Professionals

When it comes to sourcing tantalum wire, quality is paramount. We understand this need deeply. That’s why we prioritize the highest standards in every aspect of our tantalum wire production.

Our commitment to quality begins with the raw materials. We source only the finest grade tantalum. This ensures superior performance and durability.

From initial processing to the final product, each step undergoes strict scrutiny. This approach guarantees that our tantalum wire meets the highest industry standards.

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_empty_space][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Our Tantalum Wire Specification

Whether you need tantalum wire in specific diameters, lengths, or purity levels, we can accommodate. Our production flexibility allows us to offer a range of customization options.

Grade: R05200, R05400, R05252(Ta-2.5W), R05255(Ta-10W), R05240(Ta-40Nb)

Standard: ASTM B365-98, ASTM F560(Medical Grade)

Purity: Ta >99.9% or >99.95%

Elevate your projects with our Premium tantalum wire: precision sizes from 0.1 mm to 4 mm for superior performance[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

| Diameter, Inch (mm) | Tolerance, +/-Inch (mm) |

|---|---|

| 0.010~0.020 (0.254~0.508) | 0.0005 (0.013) |

| 0.020~0.030 (0.508~0.762) | 0.00075 (0.019) |

| 0.030~0.060 (0.762~1.524) | 0.001 (0.025) |

| 0.060~0.090 (1.524~2.286) | 0.0015 ( 0.038) |

| 0.090~0.125 (2.286~3.175) | 0.002 (0.051) |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Why Choose Our Tantalum Wires?

When selecting a supplier for tantalum wires, the decision goes beyond just the product. It’s about choosing a partner who can offer expertise, quality, customization, and assurance. Here’s why our tantalum wires stand out as the best choice.

Industry-Leading Expertise and Support

With years of experience in the field, we possess deep knowledge about tantalum and its applications. This expertise is crucial in helping you select the right wire for your specific needs.

Improved Tantalum Wire Quality

Heat and Surface Treatment Optimization:

Decreased surface defects in tantalum wire by refining treatment processes and raw material control, reducing defect rate to 0.25%.

Enhanced Rolling Process:

Achieved a stable burr rate of 0.2% in tantalum wire through better surface quality control.

Drawing Machine and Die Adjustments:

Reduced wire corrugation to 0.04% by optimizing machine parts and die positioning.

Guide Wheel Improvements:

Lowered the rate of bending-related defects to 0.24%.

Strictest Tolerance:

Our production process adheres to the strictest tolerances, guaranteeing that each tantalum wire delivers consistent and exacting performance.

Exceptional Purity Levels:

Our tantalum wires boast an impressive purity of up to 99.97%, ensuring top-tier quality and performance in every application.

Customized Solutions for Diverse Needs

Recognizing the diverse needs of our clients, we specialize in application-specific solutions, tailoring our tantalum wires to your unique requirements.

Certifications and Quality Standards

Each wire is crafted to align with rigorous international standards, boasting both ISO certification and adherence to ASTM guidelines.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Applications in Industry and Technology

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””]

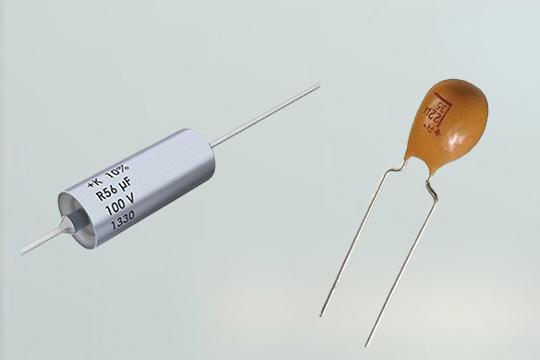

For Capacitor Leads

Capacitor grade tantalum wire, used in high-quality capacitors, is purer and smoother than other types. It’s strong with few defects. The wire ranges from 0.15mm to 1.0mm thick.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

Medical Grade Tantalum Wire

Tantalum can be made into ultra-thin wires, thinner than human hair. They are good for surgeries because they can be sterilized, don’t irritate, and are strong, but hard to knot.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

In Hot Furnaces

Tantalum wire is used in super-hot furnaces. It doesn’t melt even at extreme temperatures. This makes it great for heating elements in these furnaces.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

In Vacuum Electronics

Tantalum wire is also used in electronics that work in vacuums, like some tubes. It’s good at conducting electricity and can release electrons, which is necessary for these devices.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Manufacturing Processes for Tantalum Wire

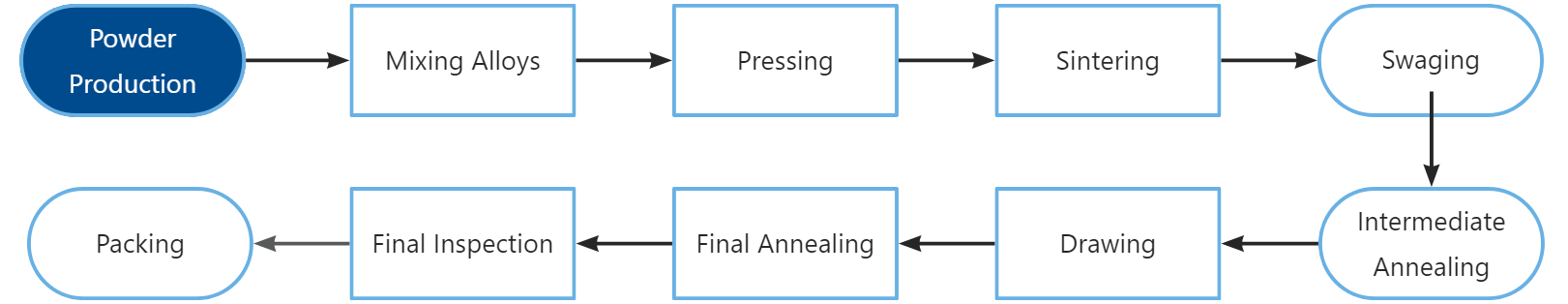

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]The manufacturing process of tantalum wire involves several key steps to ensure its quality and precision. Here’s a breakdown of the process, based on Powder Metallurgy.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Advanced Powder Production

ARS Metal uses advanced chemical reduction to create ultra-pure, uniform metal powders. This process is key for high-quality metal products.

Mixing Alloys

Our alloy mixing process is characterized by meticulous precision. This creates alloys with unmatched performance and reliability.

Precision Pressing and Shaping

Using state-of-the-art pressing techniques, we mold our metal powders into desired shapes. Our technology excels in producing complex geometries with high precision.

Sintering Process

Our sintering process employs advanced technology. It bonds powder grains effectively, creating dense and robust sinter blocks. This step is crucial for the durability of our products.

Swaging:

The tantalum is shaped by rotating and hammering. This step is crucial for initially forming the metal into a more workable shape, preparing it for further refinement.

Intermediate Annealing:

Annealing is a heating process that makes the metal more bendable and less hard. It helps make tantalum easier to shape into wire and removes any inner flaws or stress.

Drawing:

After annealing, the tantalum is pulled through different sized molds to make it thinner. This process, called drawing, is repeated several times with smaller molds each time to get the wire to the right thickness.

Final Annealing:

After the tantalum is made into wire, it goes through one last heating process. This relaxes the wire and makes it stronger and more flexible. This final step is important to make sure the wire is of good quality.

Final Product Inspection

Inspect the final Tantalum wire, including dimensional measurements, surface inspection, chemical composition analysis, etc. This ensures that the final product meets specifications.

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Tantalum Wire: A Comprehensive Guide For Buyer

What is Tantalum Wire? A Brief Overview

Tantalum wire is a refined form of the tantalum metal. It’s transformed into thin, flexible wires. These wires retain all the key properties of tantalum. This makes them valuable in various applications.

Unique Properties of Tantalum Wire vs Other Metal Wire

Tantalum wire stands out due to its distinct characteristics:

Flexibility:

Despite its strength, tantalum wire is highly flexible. This makes it easy to use in various applications.

High Melting Point:

It withstands extreme temperatures. This is crucial for high-temperature environments.

Resistance to Corrosion:

It does not corrode easily. This is true even in acidic or alkaline conditions.

Excellent Conductivity:

The wire conducts electricity efficiently. This is essential in electrical and electronic applications.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text css=””]

Grades of Tantalum Wire

| Grade | Description | Primary Applications |

|---|---|---|

| R05200 | Unalloyed, pure tantalum. Known for its corrosion resistance. | Electronics: Making fine wires for anode leads in tantalum capacitors. Fabricating wire meshes and filters used in corrosive environments. |

| R05400 | Processed for biocompatibility and purity. | Medical Devices: Crafting wires for surgical sutures and orthopedic pins. |

| R05255 (Ta-10W) | Enhanced strength and heat resistance due to tungsten. | Aerospace: Producing high-strength wires for aerospace wiring and components. |

| R05252 (Ta-2.5W) | Tailored for enhanced electrical properties. | Superconductors: Used in making ultra-thin wires for superconducting applications. |

| R05240 (Ta-40NB) | Suited for extreme conditions, combining strength and heat resistance. | Aerospace and Defense: Employed in wiring and cabling that can withstand extreme environmental conditions. |

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text css=””]

Quality Control: Tantalum Wire Testing

Quality control is key in making tantalum wire. It makes sure the wire works well for its specific use.

Tensile Strength Test:

This checks if the wire is strong. We pull the wire until it breaks to see how much force it can take.

Bend Test:

Repeatedly bend the wire to check how many times it can bend without breaking. This tells us about its flexibility and strength.

Diameter Check:

This makes sure the wire is not too thick or thin. It’s important for jobs where size matters.

Chemical Test:

This looks at what the wire is made of. It checks if the wire won’t rust and will conduct electricity well.

Surface Check:

This looks for any rough spots or problems on the wire’s surface. It’s important for uses where the wire needs to be smooth.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row]