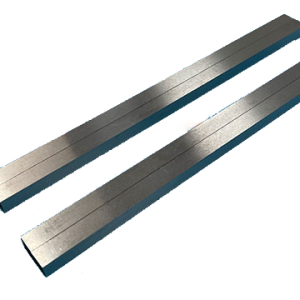

Titanium Strip

Our wide range of equipment and capabilities makes us uniquely equipped with rolling precision titanium strips to exacting dimensions. Commercially pure or unalloyed titanium strip has outstanding corrosion resistance making it the preferred material for many chemical process industries.

Titanium Strip Specifications

| Technology | Cold rolled, hot rolled |

|---|---|

| Standard | ASTM B265, ASTM F136, ASTM F67, AMS 4911, MIL 9046 |

| Grade | Gr1, Gr2, Gr3 , Gr5, Gr23, etc. |

| Condition | Cold rolled, hot rolled, annealed, quenching |

| Thickness | 0.3mm – 3mm |

| Width | 50mm – 2000mm |

| Surface | Rescaled, polished, and pickling, no burr, no oil spots |

Advantages of Titanium Strip

Low density, resistance to corrosion, and erosion-corrosion, very thin, conductive oxide surface film, smooth surface that limits adhesion of external materials, surface promotes drop-wise condensation.

Titanium Strip Applications

It is used in the chemical industry, machinery, metallurgy industry, electrolytic plating, medical industry, power plant, aerospace, petrochemical industry, navigation, military fields, and ocean engineering. Fusion welding of the commercially pure titanium grades is successful when completely protected from oxygen and nitrogen.

ARS offers controlled atmosphere annealing lines specially equipped for titanium alloys and specialized cleaning, uugerer tension leveling, slitting, edging, and oscillate winding. We also provide Tantalum / Nickel / Tungsten / Molybdenum / Zirconium / Niobium foil, and strip.

We provide a wide range of commercial titanium strip products with competitive prices of good quality.