[vc_row][vc_column][vc_column_text]

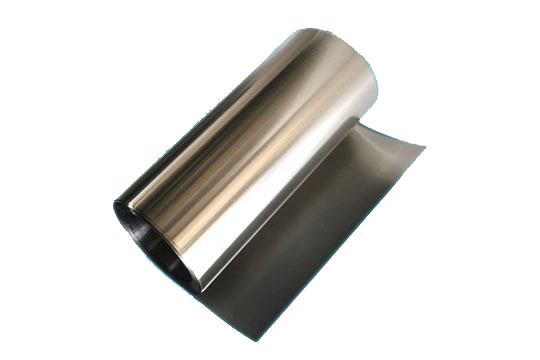

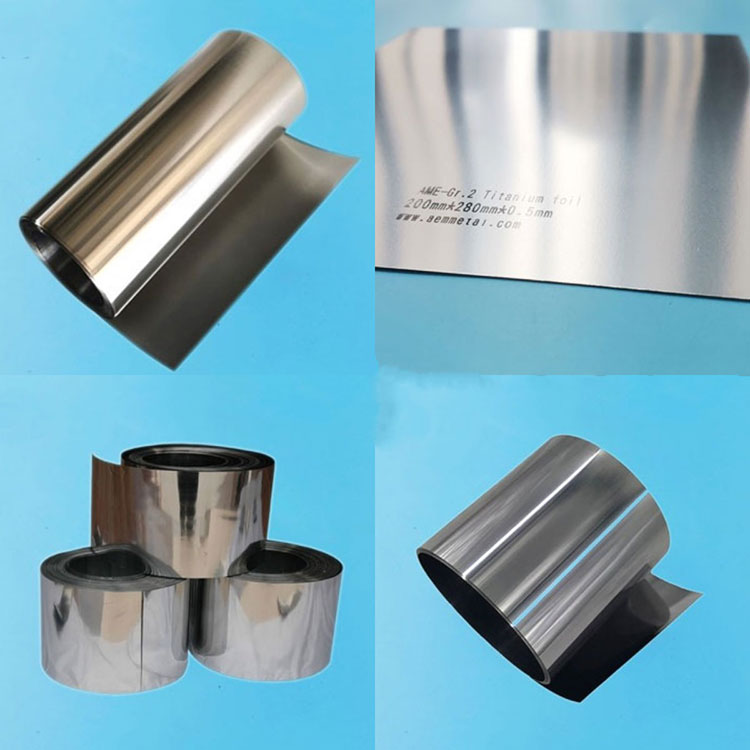

Zirconium Foil: Reliable Precision for Your Needs

Dive into the world of precision and reliability with our exceptional Zirconium Foil. At ARS METAL, we take pride in offering a diverse range of high-quality zirconium foil products designed to meet the unique needs of your projects. From standard to customized solutions, our commitment to quality shines through every layer.

Explore ARS METAL website to discover the unmatched precision, tailored options, and sustainable practices that make our zirconium foil a trusted choice across industries. Elevate your projects with the assurance of top-notch performance – that’s the essence of our Zirconium Foil offerings.

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Specifications of Zirconium Foil

| Processing | Cold-rolled, annealed |

|---|---|

| Standard | ASTM B551 |

| Thickness | 0.01 mm – 0.5 mm |

| Width | 20 – 500mm |

| Length | As you require |

| Grade | R60702, R60704, R60705 |

| Surface | No burr, no oil spots |

| Technology | Cold-rolled, annealed |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Chemical Composition of Zirconium Foil

| Grade | Element Composition (%) < | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.2 | — | 0.005 | 0.025 | 0.05 | — | 0.16 |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | — | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | — | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Why Choose ARS METAL Zirconium Foil-Our Advantages” font_container=”tag:h2|text_align:center” css=””][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

Ultra-Thin Precision:

Experience unmatched precision with our ultra-thin zirconium foil, perfect for even the most detailed projects.

High Purity:

Benefit from zirconium foil with high purity levels, minimizing impurities and ensuring optimal performance in critical applications.

Customization Excellence:

Tailor our zirconium foil to your exact specifications, offering a personalized solution that perfectly aligns with your project requirements.

Exceptional Quality Assurance:

Our zirconium foil undergoes rigorous quality control, ensuring each foil meets the highest standards for precision and performance.

Global Reputation for Reliability:

Industries worldwide trust our zirconium foil for its consistent quality, making us a reliable partner for your projects.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How to Make Zirconium Foils” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How to Make Zirconium Foils” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Melting and Alloying

The zirconium sponge is melted in an induction furnace. Alloying may occur by introducing other elements to achieve specific properties or meet application requirements.

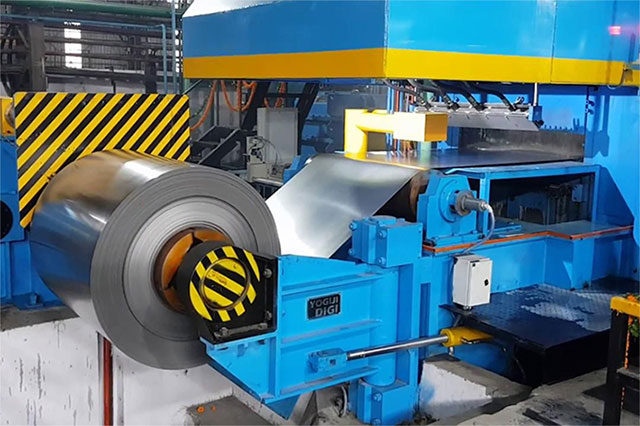

Casting or Rolling

The molten zirconium is either cast into an initial form or passed through a rolling mill to create an initial sheet or strip. This step establishes the basic shape and thickness.

Hot Rolling

The pre-shaped zirconium undergoes hot rolling to gradually thin it out while ensuring uniformity. This process improves the foil’s mechanical properties.

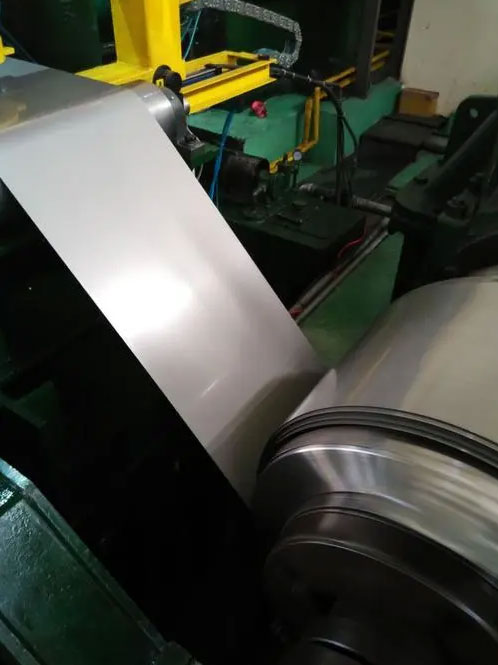

Cold Rolling

The hot-rolled zirconium foil undergoes a series of cold rolling processes to achieve the final desired thickness. Cold rolling refines the surface finish and ensures thickness uniformity.

Annealing

The zirconium foil is then subjected to annealing, a heat treatment process where the material is heated to a specific temperature and then slowly cooled. This relieves internal stresses, improves grain structure, and enhances overall mechanical properties.

Surface Treatment

Depending on the application, the zirconium foil may undergo surface treatments such as polishing, coating, or other processes to enhance specific properties.

Cutting

The final zirconium foil is cut to the desired dimensions using cutting machines.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Quality Detection of Zirconium Foils” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Quality Detection of Zirconium Foils” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Thickness and Surface Quality

Check for uniform thickness and a smooth, flawless surface. Use tools like calipers or micrometers, and visual aids such as magnifiers or optical microscopes.

Purity and Chemical Analysis

Use spectrometers or chemical analyzers to determine the purity and composition of zirconium, ensuring it meets specified standards.

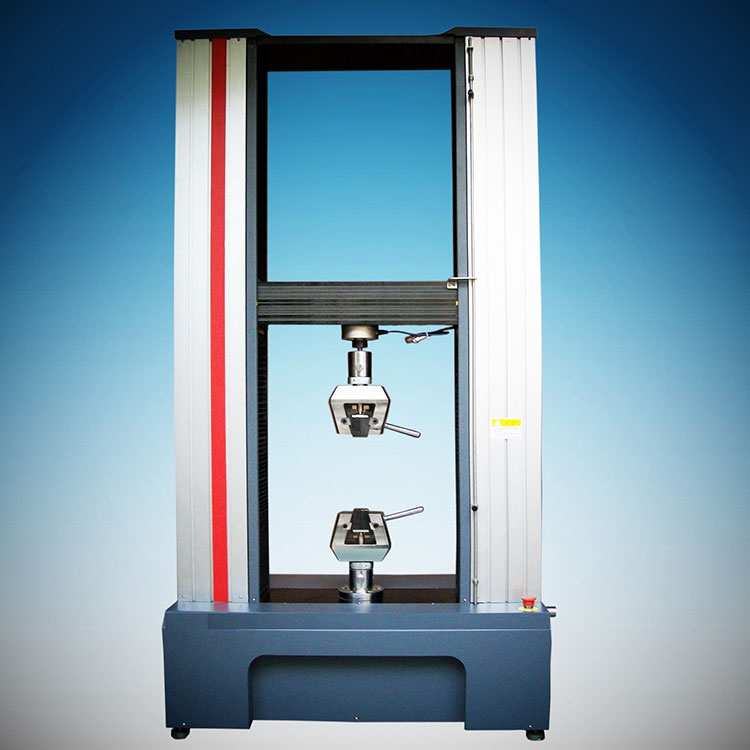

Mechanical Properties

Assess tensile strength, elongation, and microstructure for mechanical reliability. Use tensile testing machines to assess tensile strength and elongation properties.

Corrosion Resistance and Conductivity

Use a corrosion testing device to assess the foil’s resistance to corrosive conditions, and employ electrical conductivity meters to evaluate the zirconium foil’s electrical properties.

Annealing Effectiveness

Ensure proper annealing to enhance grain structure and reduce stress. Utilize tools like hardness testers to assess the annealing process’s effectiveness.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Where Our Zirconium Foil Shines-Diverse Applications” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/5″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Where Our Zirconium Foil Shines-Diverse Applications” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/5″][vc_column_text css=””]

Nuclear Industry

Zirconium foil is vital in nuclear reactors for its corrosion resistance and ability to withstand high temperatures, protect the fuel from corrosion and ensure its integrity.

[/vc_column_text][/vc_column][vc_column width=”1/5″][vc_column_text css=””]

Aerospace

Zirconium foil, due to its lightweight and high corrosion resistance, is widely used in aerospace components such as aircraft frames, engine parts, and heat shields, making it the perfect material for these rigorous applications.

[/vc_column_text][/vc_column][vc_column width=”1/5″][vc_column_text css=””]

Chemical

Zirconium foil, with its high resistance to chemicals, acids, and alkalis, is an invaluable resource for chemical processing equipment, lab crucibles, and containers. Its ability to endure harsh environments and corrosive substances without degradation further enhances its value.[/vc_column_text][/vc_column][vc_column width=”1/5″][vc_column_text css=””]

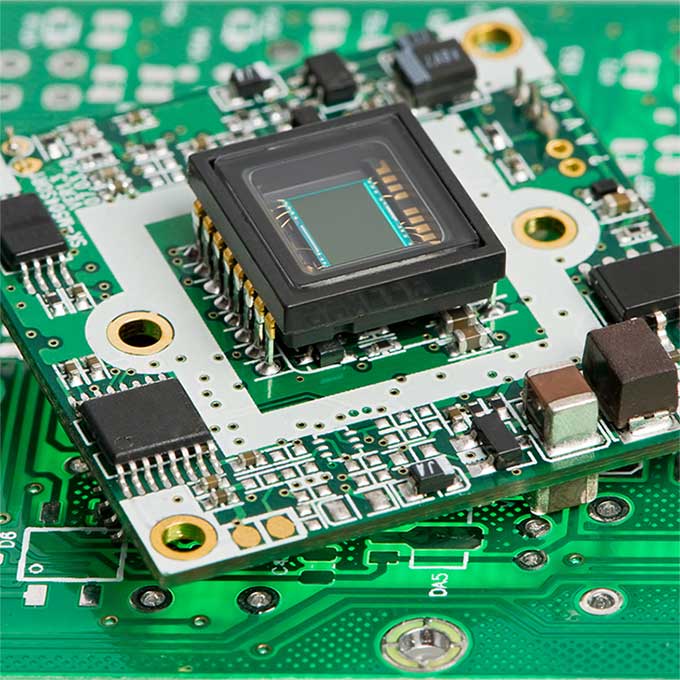

Electronics

Zirconium foil, known for its superior electrical conductivity, is used in electronic components like capacitors, sensors, and electrodes. Its high melting point and thermal stability contribute to the reliability and lifespan of electronic devices.[/vc_column_text][/vc_column][vc_column width=”1/5″][vc_column_text css=””]

Medical Devices

Zirconium foil is widely used in the medical field for implants, prosthetics, and medical devices due to its biocompatibility and resistance to body fluids. This makes it ideal for surgical tools and dental applications.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How Zirconium Foil Outperforms Its Competitors” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]Zirconium foil could compete with other thin metal foils made from materials like titanium, niobium, tantalum, and stainless steel. Each material has unique properties, with the choice depending on specific application needs. Here’s why zirconium foil might be a better option than some of these alternatives:

Corrosion Resistance:

Zirconium foil excels in corrosive environments, offering superior corrosion resistance compared to materials like stainless steel, making it a preferred choice in chemical processing and corrosive applications.

Biocompatibility:

In medical applications, zirconium foil’s biocompatibility surpasses some other metals, making it a preferred choice for certain medical devices and implants.

Lightweight Properties:

Zirconium is relatively lightweight, making it a favorable choice in industries where weight is a critical factor. It may outperform materials like stainless steel in specific weight-sensitive applications.

Thermal Stability:

Zirconium foil maintains stability across a wide temperature range, making it suitable for applications in extreme heat or cold conditions. This characteristic may give it an advantage over other materials in certain high-temperature environments.

Electrical Properties:

Zirconium’s electrical properties make it suitable for electronic applications where other materials like stainless steel or titanium may not offer comparable conductivity.

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Zirconium Foil Package” font_container=”tag:h2|text_align:center” css=””][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Zirconium Foil Package” font_container=”tag:h2|text_align:center” css=””][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row]