[vc_row][vc_column][vc_column_text]

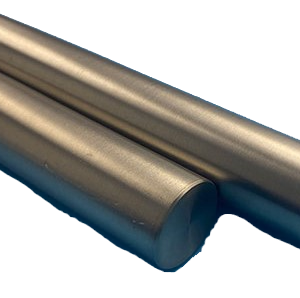

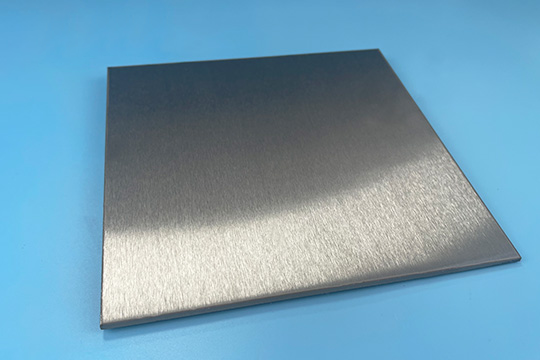

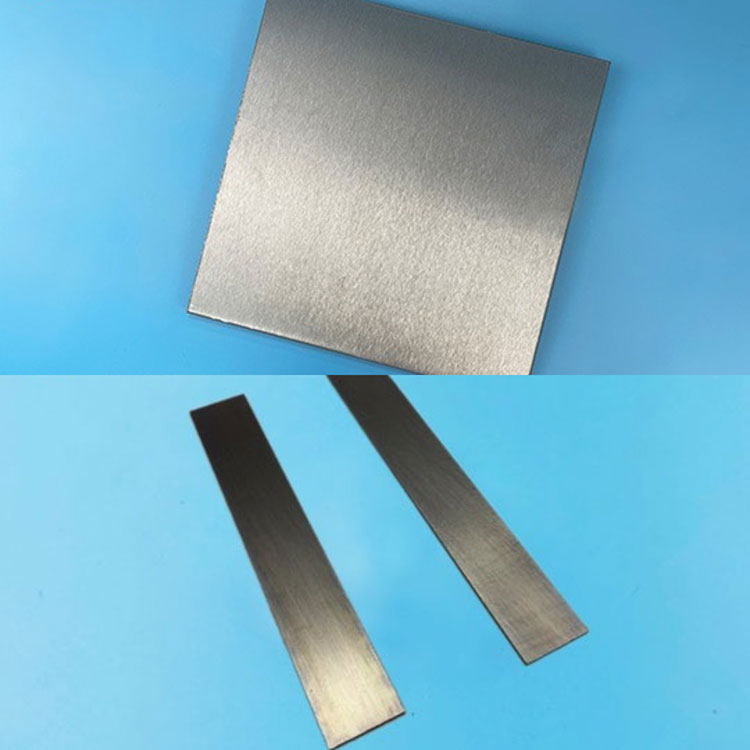

Zirconium Plate – High-Quality Solution for Your Needs

ARS METAL has a fine rolling and annealing technology to supply the perfect Zirconium Plate (Zirconium Sheet).

Our zirconium plates are engineered to international standards and specifications, and they undergo the highest level of quality control. Engineering standards defining the chemical composition, mechanical properties, and tolerance of sheets complement fully independent testing.

Choose ARS METAL, We also have shearing capabilities to meet your specific project needs.

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

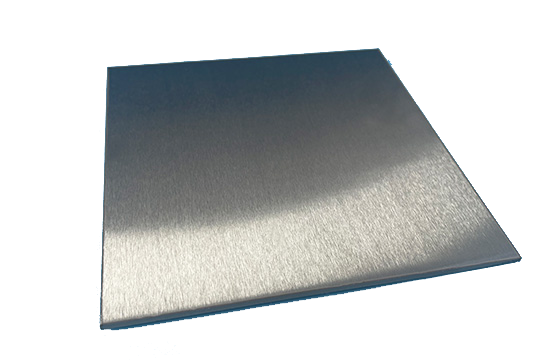

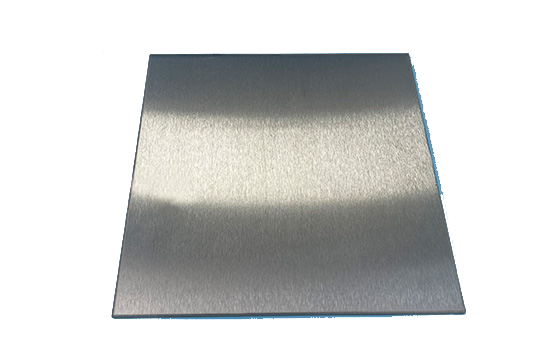

Zirconium Plate Properties

| Standard | ASTM B551 |

|---|---|

| Grade | R60702, R60704, R60705 |

| Thickness | 0.5mm – 50 mm |

| Width | 10mm – 2500mm |

| Technology | Hot-rolled, cold-rolled, hot forging, machining |

| Condition | Annealed (M),cold rolled(Y), hot rolled(R) , quenching(C) |

| Surface | Chemically cleaning or machined to be bright. Dependent on different thicknesses. |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text css=””]

| Grade | Element Composition (%) < | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.2 | — | 0.005 | 0.025 | 0.05 | — | 0.16 |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | — | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | — | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Why Choose ARS METAL Zirconium Plate-Our Advantages” font_container=”tag:h2|text_align:center” css=””][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Premium Quality and Purity

Crafted from high-purity zirconium, our plates offer premium quality, ensuring exceptional performance in challenging industrial environments.

Exceptional Corrosion Resistance and Strength

With unmatched corrosion resistance and superior mechanical strength, our zirconium plates provide long-lasting durability in aggressive chemical settings and heavy-duty applications.

Precision Customization

Tailor our zirconium plates to your exact needs with precision thickness, dimensions, and customizable surface finishes, ensuring seamless integration into diverse projects.

Versatility and Temperature Stability

From extreme heat to cold environments, our zirconium plates exhibit stability across a wide temperature range, making them versatile for various industrial and engineering applications.

Reliability Through Consistency

Experience the assurance of consistent quality across all batches, supported by comprehensive testing and certifications, minimizing the risk of performance variations and ensuring long-term durability.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How to Make Zirconium Plates?” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How to Make Zirconium Plates?” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

1. Melting and Casting:

Zirconium sponge is melted using electron beam or vacuum arc melting techniques. The molten zirconium is cast into ingots, which serve as the raw material for further processing.

2. Hot Rolling:

The zirconium ingots are heated and passed through hot rolling mills to reduce their thickness and achieve the desired dimensions. This hot rolling process helps in shaping the zirconium into a preliminary form.

3. Intermediate Annealing:

Intermediate annealing involves heating the partially rolled zirconium to remove stresses and improve its workability. This step enhances the material’s homogeneity and prepares it for further processing.

4. Cold Rolling:

The zirconium is then cold-rolled to achieve the final desired thickness and dimensions. Cold rolling increases the strength and surface finish of the material.

5. Cutting and Shearing:

The cold-rolled zirconium sheets are cut into specific sizes and shapes using cutting and shearing processes.

6. Surface Finishing:

Zirconium plates can undergo surface finishing processes, such as polishing or pickling, to achieve the desired surface texture and cleanliness.

7. Final Annealing:

The final product may undergo a final annealing process to relieve any residual stresses and optimize the material properties.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_custom_heading text=”Quality Assurance of Zirconium Plate” font_container=”tag:h2|text_align:center” css=””][vc_empty_space][vc_empty_space][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_custom_heading text=”Quality Assurance of Zirconium Plate” font_container=”tag:h2|text_align:center” css=””][vc_empty_space][vc_empty_space][vc_column_text css=””]

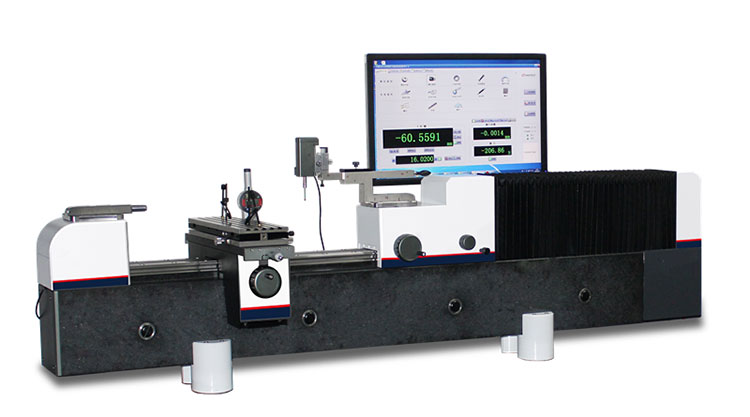

Visual Inspection

Dimensional Inspection

Chemical Composition Analysis

Hardness Testing

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][vc_column_text css=””]

[/vc_column_text][vc_column_text css=””]

Microstructure Analysis

Ultrasonic Testing

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Where Our Zirconium Plate Shines-Diverse Applications” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

Chemical Processing

Due to its excellent corrosion and oxidation resistance, zirconium plate is widely used in the manufacture of chemical equipment, such as reactors, storage tanks and so on.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Aerospace Industry

Due to its high strength, high hardness and high temperature resistance, zirconium plate is widely used in key components such as structural parts, engine parts and combustion chambers of aerospace vehicles.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

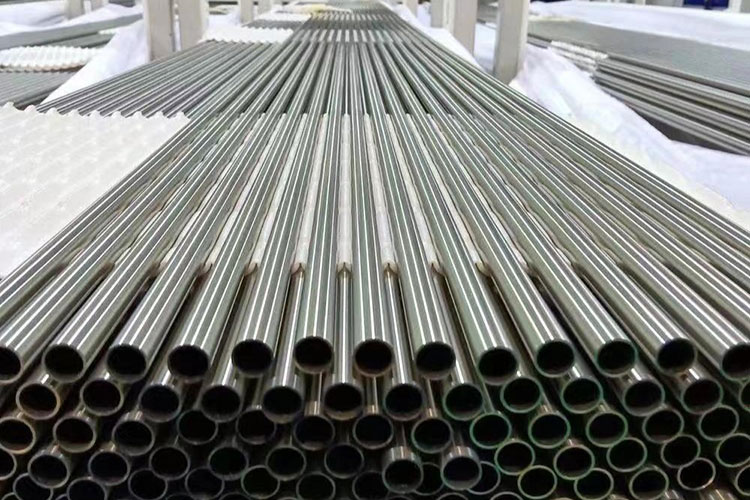

Nuclear Reactors

Due to its excellent corrosion resistance and high-temperature stability, zirconium plate is widely used in key components of nuclear reactors such as fuel elements, nuclear fuel cladding and nuclear fuel heat transfer tubes.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

Medical Implants

Due to its biocompatibility, non-magnetism and good corrosion resistance, zirconium plate is widely used in the manufacture of artificial joints, dental implants, pacemakers and other medical devices.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

Heat Exchangers

Due to its excellent heat transfer properties, zirconium plate is used in heat exchangers. Zirconium’s high thermal conductivity and corrosion resistance make it ideal for applications where heat transfer is required.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Difference between Zirconium Plate and Zirconium Sheet” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]The terms “Zirconium Plate” and “Zirconium Sheet” are often used interchangeably, but there can be slight nuances in their meaning.

Thickness:

Zirconium Plate: Generally refers to a flat, broad piece of zirconium with a thickness greater than 6mm. Plates are often associated with thicker sections used in heavy-duty applications.

Zirconium Sheet: Typically implies a thinner piece of zirconium with a thickness of less than 6mm. Sheets are commonly used for applications where a lower thickness and lighter weight are crucial.

Applications:

Zirconium Plate: Primarily utilized in heavy industries and applications where mechanical strength and durability are paramount. Examples include structural components in chemical processing equipment or aerospace applications.

Zirconium Sheet: More commonly used in applications where a lighter material is sufficient. This can include thin-walled containers, electronic components, or applications where weight is a critical factor.

In many cases, the choice between “plate” and “sheet” might be influenced by the specific requirements of a project, including factors like strength, weight, and intended use.

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How Zirconium Plate Outperforms Its Competitors” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]Compared with other plates such as tantalum plates, titanium plates, Hastelloy plates and so on, zirconium plate has the following advantages that make it stand out and become the first choice in some industries.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”How Zirconium Plate Outperforms Its Competitors” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]Compared with other plates such as tantalum plates, titanium plates, Hastelloy plates and so on, zirconium plate has the following advantages that make it stand out and become the first choice in some industries.

Corrosion Resistant

Zirconium plates, coated with a nanometre-thick passivation layer, are highly resistant to corrosion, including acids, alkalis, and most laboratory solvents. The only common acid that can corrode them is hydrofluoric acid.

Great high-temperature performance

Zirconium plates, with a high melting point of 1,855°C, are superior to most metals in high-temperature conditions. This feature is beneficial in producing zircalloys, enhancing their melting point and making them ideal for use in high-temperature applications.

Strong oxidation resistance

Zirconium plates, with their excellent oxidation resistance, can withstand long-term use in oxidative environments.

Low Neutron Absorption Ability

Zirconium plate, due to its low neutron-capture cross-section, shields fuel from nuclear fission, preventing premature or hazardous chain reactions and maintaining control over the process.

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Zirconium Plate Package” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Zirconium Plate Package” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Wooden case, plywood case, or according to clients’ demand.

[/vc_column_text][/vc_column][/vc_row]