[vc_row][vc_column][vc_column_text]

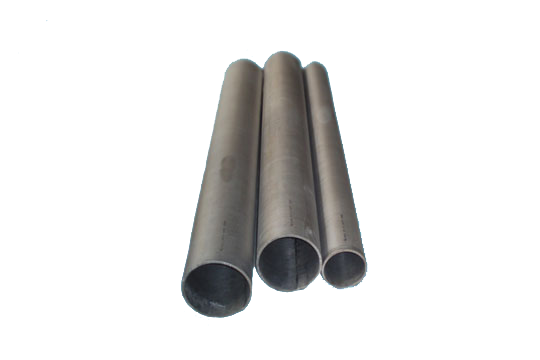

Premium Zirconium Tube for Superior Performance

Welcome to ARS METAL! We’re experts in making top-quality zirconium tubes. Our commitment to quality comes from our strong values and constant pursuit of perfection. We know zirconium tubes are vital, and we’re here to meet the highest standards.

Explore endless possibilities with our exceptional zirconium tubes at ARS METAL. We use cutting-edge technology to make durable and precise tubes. No matter your industry, we’ve got you covered. On this page, discover our product details, technical details, and real-world applications. ARS METAL is the trusted choice for excellent zirconium tube solutions. Join us on this journey!

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Specifications of Zirconium Tube

| Technique | Zirconium welded tube, zirconium seamless tube |

|---|---|

| Grade | R60702, R60704, R60705 |

| Standard | ASTM B523, ASTM B353, ASTM B658 |

| Size | OD(0.5-200)mm*WT(0.1-20)mm*L(MAX 20000)mm |

| Shape | Round, square |

| Surface | Polished or according to customer’s requirement |

| Processing | Hot rolling, cold rolling, drawing, extruding |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_column_text css=””]

Chemical Composition of Zirconium Tube

| Grade | Element Composition (%) < | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.2 | — | 0.005 | 0.025 | 0.05 | — | 0.16 |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | — | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | — | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Mechanical Properties of Zirconium Tube

| Material | State | Rm (≥)/MPa | Rp0.2 (≥)/MPa | A50mm (≥)/% |

|---|---|---|---|---|

| Zirconium 702 | Annealed | 379 | 207 | 16 |

| (UNS R60702) | ||||

| Zirconium 704 | Annealed | 413 | 241 | 14 |

| (UNS R60704) | ||||

| Zirconium 705 | Annealed | 552 | 379 | 16 |

| (UNS R60705) |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Zirconium Tube Fittings Product Forms

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Why Choose ARS METAL Zirconium Tube-Our Advantages

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

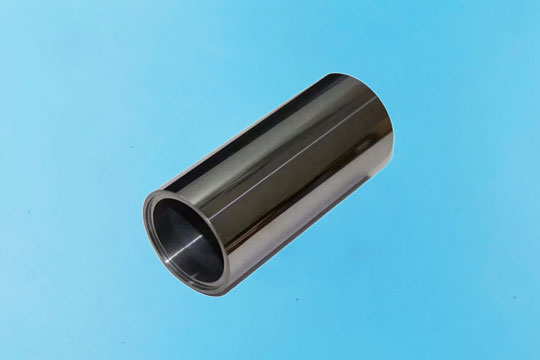

Unparalleled Quality

Our zirconium tubes are crafted with precision and adhere to the highest quality standards, ensuring durability and reliability in every application.

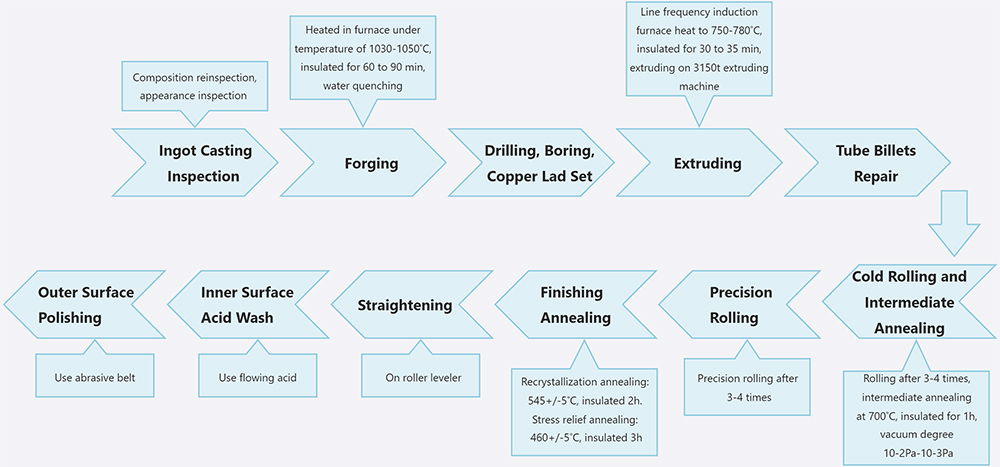

Cutting-edge Technology

We use the latest tube manufacturing technologies to ensure our products lead in innovation and deliver superior performance.

Corrosion Resistance

Our tubes are engineered to resist corrosion, making them ideal for industries where harsh chemical environments are a concern.

High-Temperature Stability

With exceptional thermal stability, our zirconium tubes maintain structural integrity even in high-temperature applications, ensuring consistent performance.

Customized Solutions

Tailored to meet your specific needs, our zirconium tubes are available in a diverse range of sizes and specifications, providing a customized solution for every project.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Quality Assurance of Zirconium Tube: Testing and Certifications

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Quality Assurance of Zirconium Tube: Testing and Certifications

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

Chemical Composition Analysis

Conduct spectroscopic analysis to verify the zirconium tube’s chemical composition, ensuring it meets the specified alloy requirements.

Dimensional Inspection

Employ precise measurements and dimensional checks to confirm that the zirconium tube adheres to the specified dimensions and tolerances.

Non-Destructive Testing (NDT)

Utilize NDT methods such as ultrasonic testing, eddy current testing, or radiographic testing to identify internal and surface defects without affecting the tube’s integrity.

Heat Treatment Verification

Verify the effectiveness of the heat treatment process by conducting metallurgical examinations to ensure proper grain size and distribution.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

Surface Finish Inspection

Evaluate the surface finish through visual inspection and surface profilometry to ensure a smooth and defect-free surface.

Mechanical Property Testing

Perform tests such as tensile testing, hardness testing, and impact testing to assess the mechanical properties, ensuring the tube meets strength and durability requirements.

Corrosion Resistance Testing

Subject the zirconium tube to corrosion resistance tests, such as salt spray testing, to assess its performance in challenging environments.

Hydrostatic Testing

Conduct hydrostatic tests to evaluate the tube’s ability to withstand internal pressure, ensuring it meets safety and performance standards.

Certifications

Obtain relevant certifications and adhere to industry standards to demonstrate compliance with quality requirements. We produce high-quality zirconium (Zr702, Zr704, Zr705), and its alloy (Zr2, Zr4), according to ASTM standards.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Applications Across Industries: Zirconium Tube in Action

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

Chemical Processing

Zirconium tubes are widely used in the chemical industry for handling corrosive chemicals and acids. Their resistance to corrosion makes them suitable for reactors, heat exchangers, and other chemical processing equipment.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

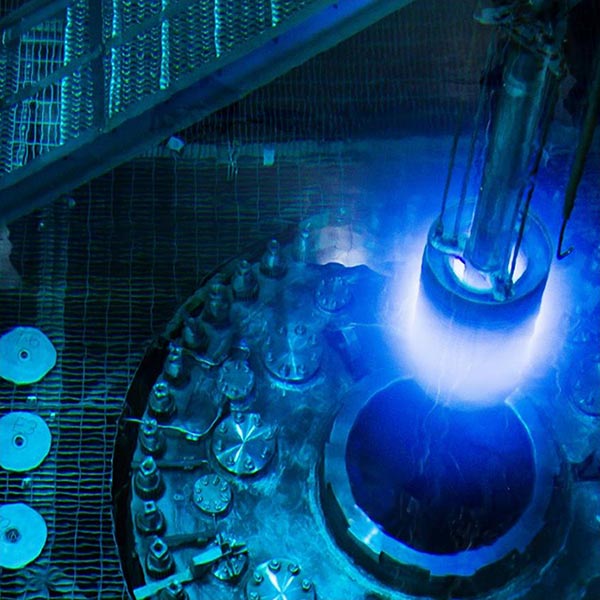

Nuclear Power

Zirconium is a crucial material in nuclear reactors. Zirconium tubes are used in fuel assemblies for their low neutron absorption characteristics, allowing efficient energy production in nuclear power plants.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Aerospace

Zirconium tubes are utilized in aerospace applications, particularly in the manufacturing of components for aircraft engines and other aerospace systems. Their lightweight nature and resistance to high temperatures contribute to their suitability in this industry.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

Heat Exchangers and Condensers

Zirconium tubes are commonly used in the construction of heat exchangers and condensers, particularly in industries where resistance to corrosion and high temperatures is crucial.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Offshore Aquaculture

Due to their corrosion resistance and suitability for use in marine environments, zirconium tubes can be used for aquaculture piping systems, desalination units, seawater filtration systems, hydraulic systems and so on.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Marine Industry

Zirconium tubes are used for the manufacture of corrosion-resistant structural components in offshore engineering equipment and ships. The excellent corrosion resistance of zirconium alloys makes zirconium tubes an ideal material for use in seawater, which contains a large amount of salts and chlorides that are extremely corrosive to metallic materials.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”How Zirconium Tube Outperforms Its Competitors

” font_container=”tag:h2|text_align:center” css=””][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

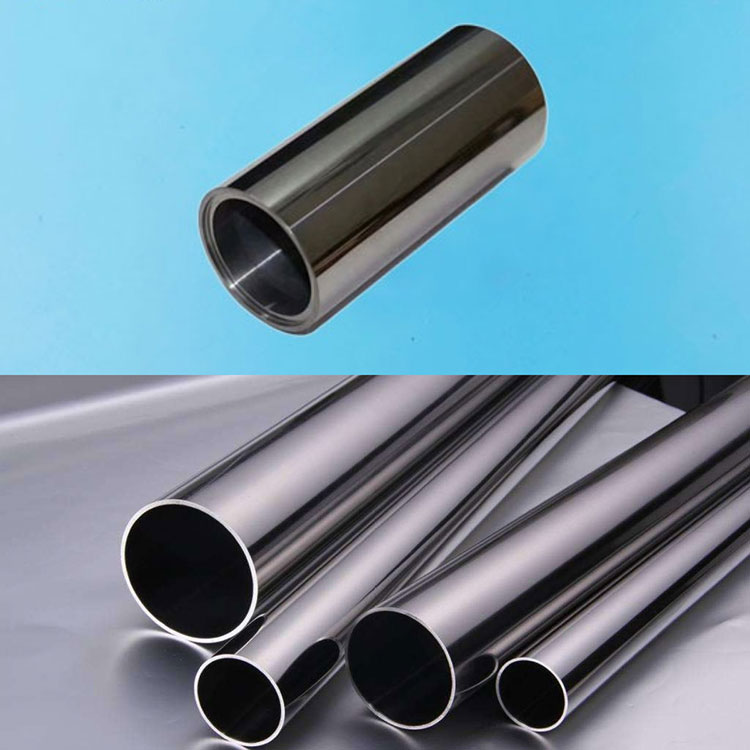

Zirconium Tubes vs. Stainless Steel Tubes:

Stainless Steel Tubes: Stainless steel is commonly used in corrosive environments.

Advantages of Zirconium Tubes:

Superior Corrosion Resistance: Zirconium tubes outperform stainless steel in aggressive chemical environments. High-Temperature Stability: Zirconium tubes maintain structural integrity in high-temperature applications better than stainless steel.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Zirconium Tubes vs. Stainless Steel Tubes:

Stainless Steel Tubes: Stainless steel is commonly used in corrosive environments.

Advantages of Zirconium Tubes:

Superior Corrosion Resistance: Zirconium tubes outperform stainless steel in aggressive chemical environments. High-Temperature Stability: Zirconium tubes maintain structural integrity in high-temperature applications better than stainless steel.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Zirconium Tubes vs. Hastelloy Tubes:

Hastelloy Tubes: Hastelloy alloys are corrosion-resistant and used in chemical processing.

Advantages of Zirconium Tubes:

Comprehensive Corrosion Resistance: Zirconium tubes offer excellent resistance to a diverse array of aggressive chemicals. Resistance to Strong Acids: Zirconium tubes outperform Hastelloy in resisting corrosion from strong acids.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Zirconium Tubes vs. Inconel Tubes:

Inconel Tubes: Inconel is known for its high-temperature resistance and corrosion resistance.

Advantages of Zirconium Tubes:

Enhanced Corrosion Resistance: Zirconium tubes demonstrate superior corrosion resistance, particularly in severe chemical conditions. Wider Chemical Compatibility: Zirconium tubes are compatible with a broader range of chemicals compared to Inconel.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Zirconium Tubes vs. Plastic Tubes (e.g., PTFE):

Plastic (e.g., PTFE) Tubes: Plastic tubes are used in some corrosive environments due to their chemical resistance.

Advantages of Zirconium Tubes:

High-Temperature Stability: Zirconium tubes maintain structural integrity in high-temperature applications, outperforming plastic. Greater Mechanical Strength: Zirconium tubes provide better overall mechanical strength compared to certain plastic materials.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row]

[/vc_column_text][/vc_column][/vc_row]