Tantalum Powder

Tantalum powder can be divided into three categories: capacitor tantalum, metallurgical tantalum, and voltage tantalum powder.

High-capacitance Tantalum Powder Series

Features:

• Excellent materials for making chips, impregnated tantalum electrolytic capacitors, and organic polymer capacitors. It has the advantages of good moldability, high specific capacitance, small leakage current, and low equivalent series resistance.

Electrical Properties

| Grade | Capacitance(+10%-6%) (μFV/g) |

Volume Shrinkage (%) |

Current Leakage (nA/μFV) |

Dissipation Factor (%) |

Breakdown Voltage (V) |

|---|---|---|---|---|---|

| FTa16-700 | 70000 | ≤15 | ≤0.5 | ≤40 | ≥120 |

| FTa16-500 | 50000 | ≤18 | ≤0.4 | ≤25 | ≥120 |

| FTa16-400 | 40000 | ≤18 | ≤0.4 | ≤20 | ≥120 |

| FTa16-300 | 30000 | ≤18 | ≤0.4 | ≤20 | ≥120 |

| FTa16-230 | 23000 | ≤18 | ≤0.4 | ≤15 | ≥140 |

Chemical Analysis (Maximum Values/wt ppm)

| Grade | O | C | N | H | Fe | Ni | Cr | Si | Ti | Nb | Na+K | W | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FTa16-700 | 4000 | 40 | 1000 | 180 | 30 | 30 | 20 | 20 | 5 | 30 | 40 | 10 | 5 |

| FTa16-500 | 3500 | 40 | 500 | 170 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-400 | 3000 | 40 | 500 | 170 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-300 | 2500 | 30 | 400 | 120 | 30 | 30 | 20 | 20 | 5 | 30 | 30 | 10 | 5 |

| FTa16-230 | 2500 | 30 | 150 | 120 | 30 | 30 | 20 | 20 | 5 | 30 | 20 | 10 | 5 |

Physical Properties

| Grade | Bulk Density(g/cm3) | Average Fisher Size(um) | Particle-size Distribution (-325mesh%) |

|---|---|---|---|

| FTa16-700 | 1.5-2.1 | 1.8-3.0 | ≤35 |

| FTa16-500 | 1.6-2.2 | 2.0-3.4 | ≤35 |

| FTa16-400 | 1.6-2.2 | 2.0-3.5 | ≤35 |

| FTa16-300 | 1.7-2.3 | 2.4-3.5 | ≤35 |

| FTa16-230 | 1.7-2.3 | 2.4-3.5 | ≤35 |

Middle-Voltage Tantalum Powder Series

Features:

• It’s suitable for making medium to high voltage solid tantalum electrolytic capacitors with high-reliability requirements from 20 to 63V.

Electrical Properties

| Grade | Capacitance(+10%-6%) (u FV/g) |

Current Leakage (nA/u FV) |

Dissipation Factor (%) |

Breakdown Voltage (V) |

|---|---|---|---|---|

| FDP-100 | 10000 | ≤0.4 | ≤10 | ≥180 |

| FDP -80 | 8000 | ≤0.4 | ≤10 | ≥230 |

| FDB -52 | 5200 | ≤0.5 | ≤8 | ≥240 |

| FTa40-42 | 4200 | ≤0.5 | ≤8 | ≥240 |

Chemical Analysis (Maximum Values/wt ppm)

| Grade | O | C | N | Fe | Ni | Cr | Si | Ti | Nb | Na | K | W | Mo | Al | Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FDP-100 | 2200 | 60 | 100 | 50 | 10 | 15 | 20 | 5 | 30 | 15 | 15 | 20 | 10 | 5 | 5 |

| FDP-80 | 2100 | 60 | 100 | 50 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

| FDB-52 | 1700 | 45 | 50 | 35 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

| FTa40-42 | 1700 | 45 | 50 | 35 | 10 | 15 | 20 | 5 | 30 | 10 | 10 | 20 | 10 | 5 | 5 |

Physical Properties

| Grade | Bulk Density (g/cm3) | Average Fisher Size (um) | Particle-size Distribution (-325mesh%) |

|---|---|---|---|

| FDP-100 | 1.5-2.3 | 3.0-5.0 | ≤30 |

| FDP-80 | 1.7-2.5 | 3.0-5.0 | ≤30 |

| FDB-52 | 3.0-4.0 | 4.5-8.0 | ≤30 |

| FTa40-42 | 3.5-4.5 | 5.0-9.0 | ≤30 |

High-Voltage Tantalum Powder Series

Features:

Electrical Properties

| Grade | Capacitance (+10%-6%)(uFV/g) |

Current Leakage (nA/u FV) |

Dissipation Factor (%) |

Breakdown Voltage (V) |

|---|---|---|---|---|

| FTa50-50 | 5000 | ≤0.6 | ≤6 | ≥260 |

| FTa50-40 | 4000 | ≤0.6 | ≤6 | ≥260 |

| FDC-50 | 5000 | ≤0.7 | ≤6 | ≥300 |

| FTa63-40 | 4000 | ≤0.7 | ≤6 | ≥300 |

| FTa63-35 | 3500 | ≤0.7 | ≤6 | ≥300 |

| FTa63-28 | 2800 | ≤0.7 | ≤5 | ≥300 |

| FTa63-25 | 2500 | ≤0.7 | ≤4 | ≥300 |

| FTa63-20 | 2000 | ≤0.7 | ≤3 | ≥300 |

| FTa63-15 | 1500 | ≤0.7 | ≤3 | ≥300 |

| FTa63-10 | 1000 | ≤0.7 | ≤3 | ≥300 |

Chemical Analysis (Maximum Values/wt ppm)

| Grade | O | N | C | Fe | Ni | Cr | Si | Ti | Nb | W | Mo | AL | Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FTa50-50 | 1800 | 60 | 50 | 40 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa50-40 | 1600 | 60 | 50 | 40 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FDC-50 | 2000 | 60 | 60 | 50 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-40 | 1800 | 60 | 40 | 35 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-35 | 1600 | 60 | 40 | 30 | 15 | 15 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-28 | 1400 | 40 | 30 | 20 | 10 | 10 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-25 | 1400 | 40 | 30 | 20 | 10 | 10 | 20 | 10 | 30 | 10 | 10 | 5 | 5 |

| FTa63-20 | 1200 | 40 | 25 | 15 | 10 | 10 | 20 | 5 | 30 | 10 | 10 | 5 | 5 |

| FTa63-15 | 1000 | 40 | 25 | 15 | 10 | 10 | 20 | 5 | 30 | 10 | 10 | 5 | 5 |

| FTa63-10 | 1000 | 40 | 25 | 15 | 10 | 10 | 20 | 5 | 30 | 10 | 10 | 5 | 5 |

Physical Properties

| Grade | Bulk Density(g/cm3) | Average Fisher Size(μm) |

|---|---|---|

| FTa50-50 | 2.5-3.5 | 5.5-7.5 |

| FTa50-40 | 3.0-4.0 | 7.5-11.0 |

| FDC-50 | 2.5-3.5 | 4.0-7.0 |

| FTa63-40 | 3.5-4.5 | 8.0-11.0 |

| FTa63-35 | 3.5-4.5 | 8.0-12.0 |

| FTa63-28 | 3.5-5.5 | 8.0-12.0 |

| FTa63-25 | 4.0-6.0 | 9.0-14.0 |

| FTa63-20 | 4.0-6.0 | 8.0-13.0 |

| FTa63-15 | 5.0-6.5 | 9.0-15.0 |

| FTa63-10 | 5.5-6.5 | 10.0-20.0 |

Tantalum Powder for Metallurgical Purposes

Features:

Grade:FTa-01, FTa-02, FTa-1

| Grade | FTa-01 | FTa-02 | FTa-1 | |

|---|---|---|---|---|

| Main Content | Ta,%,Minimum | 99.95 | 99.95 | 99.95 |

| Impurity Content , %,Max |

O | 0.100 | 0.120 | 0.180 |

| C | 0.005 | 0.005 | 0.008 | |

| N | 0.005 | 0.005 | 0.008 | |

| H | 0.003 | 0.003 | 0.003 | |

| Fe | 0.004 | 0.004 | 0.005 | |

| Ni | 0.003 | 0.003 | 0.005 | |

| Cr | 0.003 | 0.003 | 0.005 | |

| Nb | 0.003 | 0.003 | 0.005 | |

| W | 0.002 | 0.002 | 0.002 | |

| Mo | 0.001 | 0.001 | 0.002 | |

| Si | 0.003 | 0.003 | 0.005 | |

| Mn | 0.001 | 0.001 | 0.001 | |

| Ti | 0.001 | 0.001 | 0.001 | |

| Fsss(um) | 3.0-10.0 | 3.0-10.0 | 3.0-10.0 | |

| Sieve Mesh | -80 | -80 | -80 | |

| Application | Tantalum processing and alloying additives | |||

| Special requirements to be agreed upon by the supplier and buyer | ||||

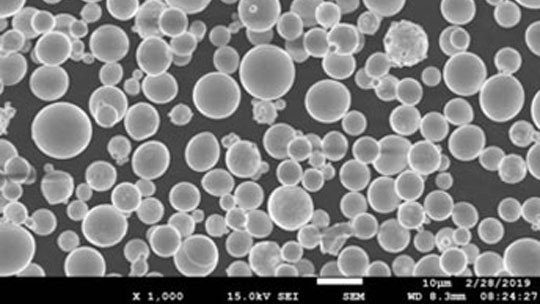

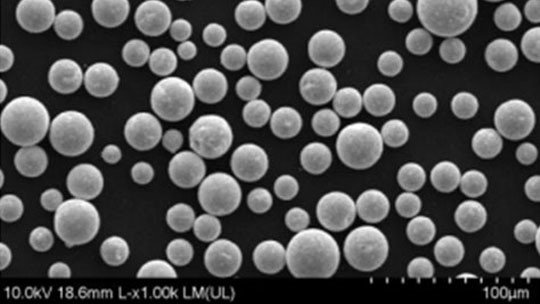

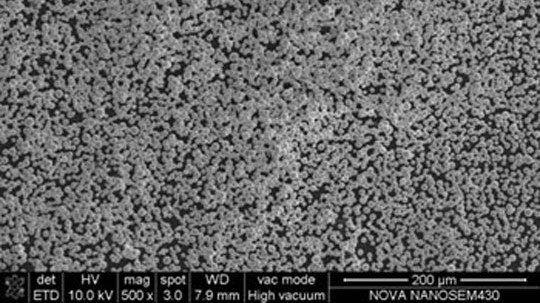

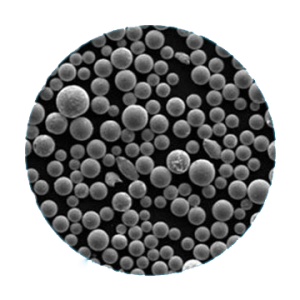

Spherical Tantalum Powder

ARS’s spherical Tantalum powder is a good choice for 3D printing technology as its high purity, uniform particle size, complete surface structure, easy dispersion, large specific surface area, and high surface activity. Our spherical Tantalum powder has a high level of sphericity and controlled grain size, which make it the ideal powder for surface coating. It is the material of choice for many applications because of its biocompatible features, among other things.

Physical Properties of Spherical Tantalum Powder

| Size | 15-53 um | ||||

|---|---|---|---|---|---|

| Apparet Density | 9.75 g/cm3 | ||||

| Tap Density | 10.8 g/cm3 | ||||

| Hall Flow Rate | 5.8 s/50g |

Chemical Composition of Spherical Tantalum Powder

| Chemical Composition – by ICP-AES | ||||||||

|---|---|---|---|---|---|---|---|---|

| Element | Ta | Fe | Mg | Cu | Al | Ca | Sn | Mn |

| Value (%) | ≥99.9 | 0.002 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Element | Ti | Mo | W | Nb | Si | Cr | Ni | |

| Value (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | |

| Gas Impurities | ||||||||

| Element | C | H | O | N | ||||

| Value (%) | 0.002 | 0.0018 | 0.045 | 0.004 | ||||

Features of Spherical Tantalum Powder

– High resistance to corrosion;

– Resistant to high temperature.

Application of Spherical Tantalum Powder

– Additive manufacturing (AM);

– Thermal spray (TSA);