Molybdenum Powder

Molybdenum powder is a dark gray or black lustrous powder. These are produced by hydrogen reduction of molybdenum trioxide and ammonium molybdates.

Physical Properties of Molybdenum Powder

F. S.S.S: 2.5um~6.0um

Bulk density: 0.85g/cm3~1.5g/cm3

Bulk density: 0.85g/cm3~1.5g/cm3

Molybdenum Powder Applications

FMo-1 is used as raw material to process the large molybdenum plate’s electrical heating element made of molybdenum silicide.

FMo-2 is used as raw material for processing molybdenum wafer, and molybdenum piercing mandrels.

Chemical Composition of Molybdenum Powder

| Grade | FMo-1 | FMo-2 | |

|---|---|---|---|

| Mo Content (%)≥ | 99.90 | 99.50 | |

| Other Elements (%) < | Pb | 0.0005 | 0.0005 |

| Bi | 0.0005 | 0.0005 | |

| Sn | 0.0005 | 0.0005 | |

| Sb | 0.0010 | 0.0010 | |

| Cd | 0.0010 | 0.0010 | |

| Fe | 0.0050 | 0.020 | |

| Al | 0.0015 | 0.0050 | |

| Si | 0.0020 | 0.0050 | |

| Mg | 0.0020 | 0.0040 | |

| Ni | 0.0030 | 0.0050 | |

| Cu | 0.0010 | 0.0010 | |

| Ca | 0.0015 | 0.0030 | |

| P | 0.0010 | 0.0030 | |

| C | 0.0050 | 0.010 | |

| N | 0.015 | 0.020 | |

| O | 0.150 | 0.250 | |

| Special requirements to be agreed upon by the supplier, and buyer | |||

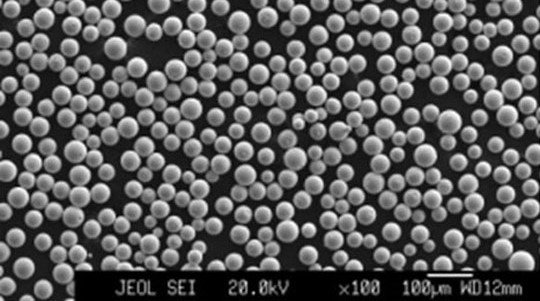

Spherical Molybdenum Powder

Our spherical Molybdenum Powder has a high level of sphericity and controlled grain size, making it the ideal powder for surface coating. It is the material of choice for many applications because it has good electrical and thermal conductivity, high melting point, and high-density. These properties are necessary to make it compatible with the most demanding industrial processes.

Physical Properties of Spherical Molybdenum Powder

| Size | 15-53 um | ||||

|---|---|---|---|---|---|

| Apparet Density | 6.25 g/cm3 | ||||

| Tap Density | 6.80 g/cm3 | ||||

| Hall Flow Rate | 11.00 s/50g |

Chemical Composition of Spherical Molybdenum Powder

| Chemical Composition – by ICP-AES | ||||||||

| Element | Mo | Pb | Bi | Sn | Sb | Cd | Fe | Al |

| Value (%) | ≥99.9 | <0.002 | <0.001 | <0.001 | <0.001 | <0.001 | <0.005 | <0.001 |

| Element | Mg | Ni | Cu | Ca | Ti | Mn | Cr | W |

| Value (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.002 | <0.001 |

| Gas Impurities | ||||||||

| Element | C | P | O | N | ||||

| Value (%) | 0.0032 | 0.001 | 0.01 | 0.0023 | ||||

Spherical Molybdenum Powder Application

– Metal injection molding (MIM);

– Thermal spray (TSA);

– Thermal spray (TSA);

Packaging of Molybdenum Powder

Packed in iron drums with inside plastic bags