In the quest for materials that can withstand extreme conditions while maintaining superior performance, molybdenum alloys stand out as a top choice. Whether you’re looking to enhance the durability of aerospace components, improve the reliability of automotive parts, or increase the lifespan of industrial machinery, molybdenum alloys offer unparalleled advantages. This comprehensive guide explores the unique properties, types, and applications of molybdenum alloys, providing a deep dive into how this material can elevate your products.

Overview of Molybdenum Alloy

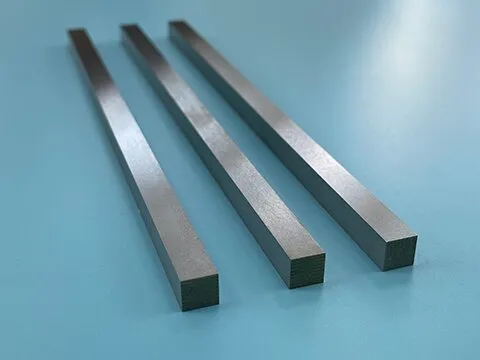

Molybdenum alloy is a class of high-performance materials characterized by its excellent mechanical properties, high thermal conductivity, and exceptional resistance to corrosion. Known for its ability to retain strength at elevated temperatures, molybdenum alloy is used across a wide range of industries, including aerospace, automotive, electronics, and construction. The alloy’s versatility and robustness make it a preferred choice for applications that require reliability and longevity.

Properties and Characteristics

Molybdenum alloys are prized for several key properties that make them suitable for demanding applications:

- Strength and Resistance: Molybdenum alloys possess a high tensile strength and can endure significant mechanical stress without deforming. This makes them ideal for heavy-duty applications where materials are subjected to high loads and pressures.

- Heat Resistance: One of the most notable properties of molybdenum alloys is their ability to maintain structural integrity at high temperatures. They can withstand environments exceeding 1,000°C, making them indispensable in industries like aerospace and automotive, where components are exposed to extreme heat.

- Corrosion Resistance: Molybdenum alloys offer excellent resistance to corrosion, especially in aggressive environments containing acids or chlorides. This property ensures longevity and reliability in chemical processing plants and other harsh settings.

- Thermal Conductivity: The high thermal conductivity of molybdenum alloys allows for efficient heat dissipation. This makes them an ideal choice for heat sinks, thermal shields, and other applications where temperature management is crucial.

Advantages of Using Molybdenum Alloy

Molybdenum alloys offer several significant advantages, making them a valuable material for a variety of applications:

- Strength-to-Weight Ratio: Despite their robust strength, molybdenum alloys are relatively lightweight. This characteristic is particularly beneficial in aerospace and automotive industries, where reducing the weight of components without compromising strength is critical for improving fuel efficiency and performance.

- Thermal Conductivity: The ability of molybdenum alloys to conduct heat efficiently is advantageous in high-temperature industrial processes. This property is also crucial in the electronics industry, where molybdenum alloys are used in the production of heat sinks and other thermal management devices.

- Wear Resistance: Molybdenum alloys are highly resistant to wear, abrasion, and erosion. This makes them an excellent choice for components that experience frequent friction and wear, such as cutting tools, molds, and dies.

- Electrical Conductivity: Certain molybdenum alloys exhibit excellent electrical conductivity, making them suitable for electrical contacts, semiconductor bases, and other electronic applications.

Types of Molybdenum Alloys

Molybdenum alloys are available in various compositions, each tailored for specific applications:

- Molybdenum-Tungsten Alloy (Mo-W): This alloy combines the toughness of molybdenum with the hardness and high melting point of tungsten. It is particularly useful in applications requiring both wear resistance and the ability to withstand high temperatures, such as cutting tools and high-performance machinery.

- Molybdenum-Rhenium Alloy (Mo-Re): Known for its exceptional high-temperature strength and resistance to thermal creep, this alloy is ideal for components exposed to extreme heat and radiation, such as rocket nozzles, turbine blades, and nuclear reactor parts.

- Molybdenum-Copper Alloy (Mo-Cu): This alloy offers a unique combination of thermal and electrical conductivity, along with good mechanical properties. It is widely used in electrical and electronic applications, including thermal management in electronic devices and heat sinks.

- TZM Alloy (Titanium-Zirconium-Molybdenum): TZM is a molybdenum-based alloy containing small amounts of titanium and zirconium. It is known for its high-temperature strength, resistance to thermal creep, and good ductility. TZM is used in a variety of high-temperature applications, including aerospace, high-temperature furnaces, and extrusion dies.

- Molybdenum-Hafnium Carbon (MHC) Alloy: This advanced alloy includes hafnium and carbon to enhance the high-temperature performance of molybdenum. MHC alloy provides superior strength and thermal stability, making it particularly suitable for applications in the aerospace and nuclear industries where extreme heat resistance is required.

Applications of Molybdenum Alloy

Due to their exceptional properties, molybdenum alloys are used in numerous industries:

- Aerospace: The aerospace industry relies on molybdenum alloys for critical components that require high strength-to-weight ratios and thermal stability. Applications include engine parts, structural elements, and landing gear components.

- Automotive: In the automotive sector, molybdenum alloys are used in high-performance engine components, transmission systems, and exhaust systems. Their ability to withstand high temperatures and resist wear makes them invaluable for enhancing vehicle performance and durability.

- Construction and Infrastructure: Molybdenum alloys are used in construction for their strength and corrosion resistance. They are found in structural components, bridges, and buildings, providing durability and long-term stability in harsh environments.

- Mining and Oil & Gas: The mining and oil & gas industries utilize molybdenum alloys for equipment that must operate in corrosive and high-wear conditions. These alloys are used in drilling equipment, pipelines, and processing machinery.

- Electronics and Electrical: Due to their thermal and electrical conductivity, molybdenum alloys are critical in the electronics industry. They are used in semiconductors, heat sinks, and other electronic components that require efficient heat management.

Comparison with Other Alloys

When selecting materials for high-performance applications, it’s essential to consider the advantages and disadvantages of different alloys:

- Molybdenum Alloy vs. Tungsten Alloy: While both molybdenum and tungsten alloys excel in high-temperature applications, molybdenum alloys offer a better strength-to-weight ratio. Tungsten, however, has a higher melting point and greater hardness, making it suitable for the most extreme conditions but at a higher weight and cost.

- Molybdenum Alloy vs. Stainless Steel: Molybdenum alloys provide superior strength and thermal stability compared to stainless steel. They are also lighter, making them more suitable for aerospace and automotive applications. However, stainless steel offers excellent corrosion resistance, especially in marine environments, and is generally more cost-effective.

- Molybdenum Alloy vs. Titanium Alloy: Both molybdenum and titanium alloys are strong and lightweight, but they serve different purposes. Titanium alloys are highly resistant to corrosion and are biocompatible, making them ideal for medical implants and environments with corrosive elements. Molybdenum alloys, on the other hand, offer better thermal stability and are often more cost-effective, making them suitable for applications requiring high-temperature performance.

Choosing the Right Alloy

Selecting the appropriate alloy depends on the specific requirements of your application. Molybdenum alloys are ideal for scenarios where high-temperature performance, strength-to-weight ratio, and resistance to wear and corrosion are critical. Tungsten alloys are preferable for applications needing extreme hardness and the highest melting points. Stainless steel offers a good balance of properties for less extreme conditions, particularly where corrosion resistance is paramount. Titanium alloys are best for lightweight, corrosion-resistant applications, especially in medical and marine environments.

Conclusion

Molybdenum alloys continue to be a cornerstone in various advanced industries due to their unique combination of properties. As technology progresses, particularly in fields like aerospace, automotive, and electronics, the demand for materials that can perform under extreme conditions is increasing. Molybdenum alloys are meeting this demand, providing solutions that enhance the performance, efficiency, and longevity of critical components.

Looking ahead, molybdenum alloys are set to play a pivotal role in emerging technologies, such as renewable energy systems and advanced electronics. Their ability to operate in high-temperature environments and resist corrosion makes them a valuable material for future innovations.

If you’re a manufacturer or industry professional looking to leverage the advantages of molybdenum alloys, our team is here to help. Contact us to explore how our tailored solutions can meet your specific needs and elevate your products to the next level of performance and durability.