AlNiCo 450 with size of Diameter 15*11.9mm, soft iron outside

AlNiCo 450 with 10.98*7.6*3.5mm

AlNiCo 5 with 22*8*5.5mm

AlNiCo 5 with Diameter 12*16mm with hole 3mm

AlNiCo 2 with 25*10*6mm

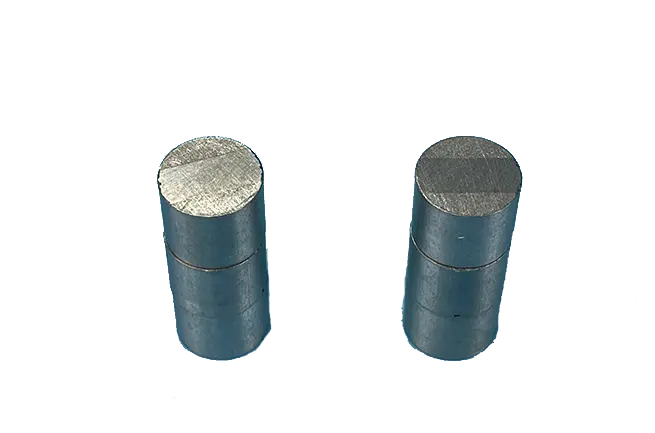

AlNiCo 8 with Diameter 6*10mm

AlNiCo 8 with Diameter 14*8mm

Customized AlNiCo Magnets for Your Individual Projects!

We understand every customer has individual needs and specifications for the AlNiCo magnets, that’s why we insist on customizing for our client, not only for design but also for manufacturing and service.

- Sizes and shapes: AlNiCo magnets come in a variety of sizes and shapes to meet the diverse needs of different applications. It’s important to note that the size and shape of AlNiCo magnets are chosen based on the intended application, available space, and required magnetic strength.

- Grades & magnetic strength:We provide a wide range of grades:

AlNiCo 5: This is one of the most widely used grades of AlNiCo magnets, often used in applications such as guitar pickups.

AlNiCo 2: This grade has a lower magnetic strength compared to AlNiCo 5. It is sometimes preferred for certain applications where a softer magnetic field is desirable, such as in specific types of pickups for musical instruments.

AlNiCo 8: This grade has a higher magnetic strength than AlNiCo 5. It is used in applications where a stronger magnetic field is required, such as in some specialized industrial applications.

AlNiCo 9: AlNiCo 9 is a less common grade that offers a balance between magnetic strength and temperature stability. It may be used in applications where both factors are important. - Working temperatures: The working temperature for AlNiCo magnets is relatively high compared to some other types of magnets. AlNiCo magnets can typically operate effectively at temperatures up to 550°C. This high-temperature stability makes them suitable for applications where elevated temperatures are encountered, such as in certain industrial and scientific environments. It’s important to note that the magnetic properties of AlNiCo magnets can be affected by temperature variations. As the temperature increases, the magnet’s magnetic strength may decrease, and it could experience some loss of magnetization. Conversely, as the temperature decreases, the magnetic strength may recover. The exact temperature performance can vary depending on the specific composition of the AlNiCo alloy. When selecting a magnet for a particular application, it’s crucial to consider the operating environment, especially if it involves extreme temperatures. If precise temperature stability is critical for the application, please consulting with us.

More Than a AlNiCo Magnets Manufacturer

Advanced Material Expertise:

Beyond AlNiCo, our material expertise spans a diverse range, incorporating cutting-edge alloys and composites. We harness materials with precision to craft solutions that meet the unique demands of modern applications.

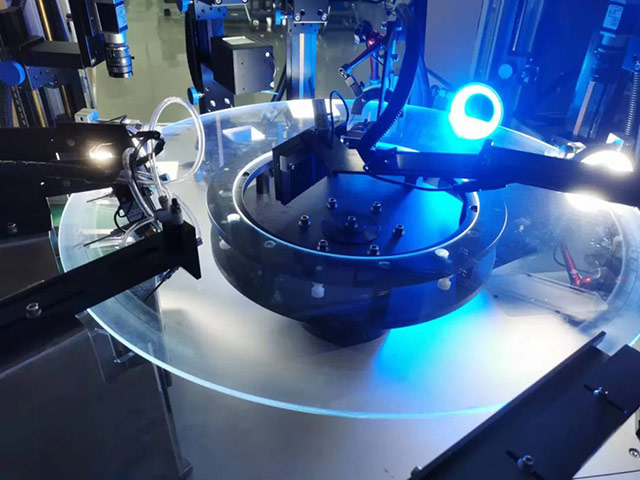

Customization Prowess:

Recognizing the varied needs of industries, we offer more than off-the-shelf products. Our customization prowess allows us to tailor magnetic solutions, optimizing size, shape, and magnetic strength to align seamlessly with specific project requirements.

Innovative Design Integration:

We are not merely suppliers but collaborators in innovation. Our team works closely with clients to integrate magnetic solutions seamlessly into their designs. From automotive applications to medical devices, our magnets are seamlessly woven into the fabric of modern technological advancements.

Responsive to Industry Challenges:

Adapting to the ever-evolving landscape of industry challenges, we stay at the forefront of research and development. Our commitment to staying abreast of emerging technologies ensures that our solutions remain not only current but also ahead of the curve.