Your Trusted Source for Neodymium Magnets Manufacturer

Are you looking for a reliable neodymium magnets manufacturer, are you searching for the strongest magnets for your application, or even expecting design for your own specificiation, I am glad you have come to the right place.

Are you eager to explore more about us, are you ready to discuss with us, let’s start!

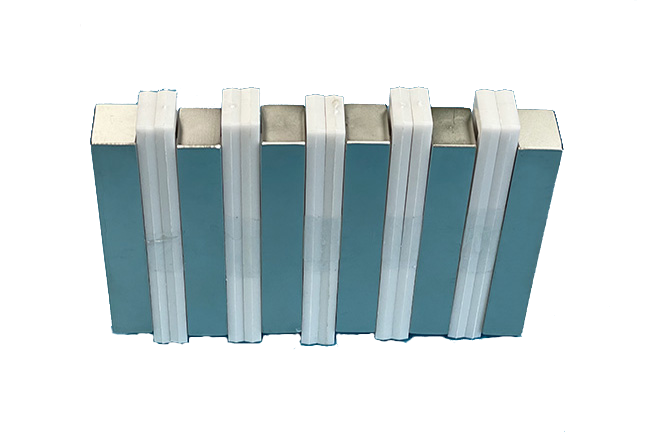

N45SH with size of 20*88*14.5mm,working temperture up to 150 degree

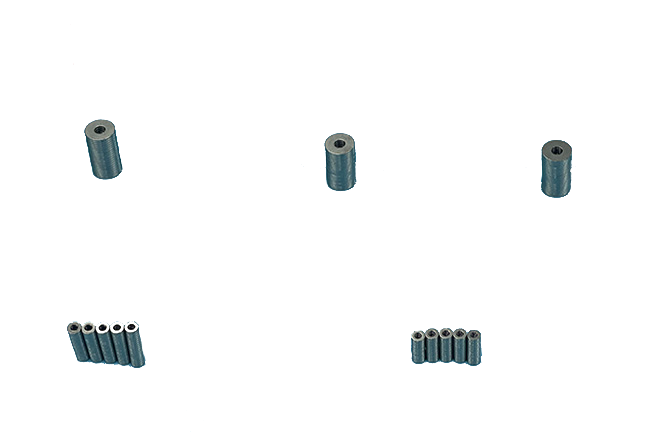

N30 with small size of OD 3*ID 1*0.5mm

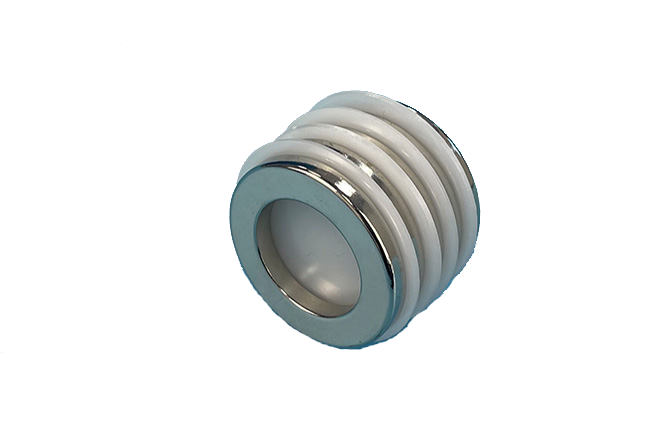

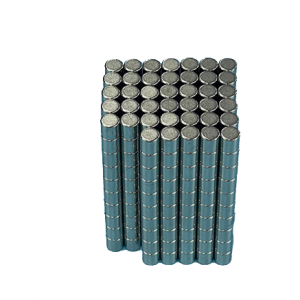

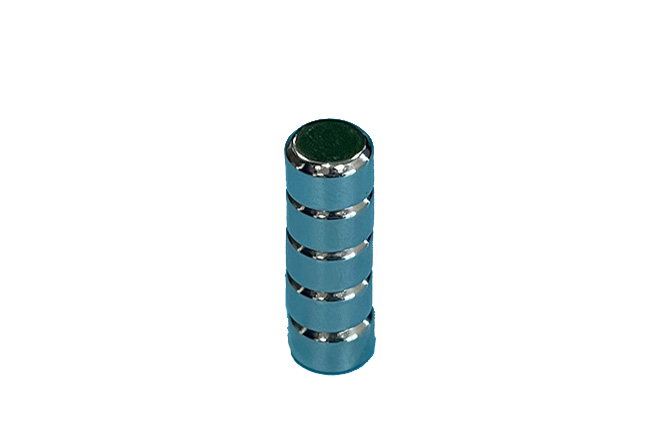

N50 with size of diameter 10*6mm, chamfer 1X45° on one side

N40 with size of 44*7.97*1mm for scissor appliaction

NdFeB plastic boned magnets with black epoxy coating

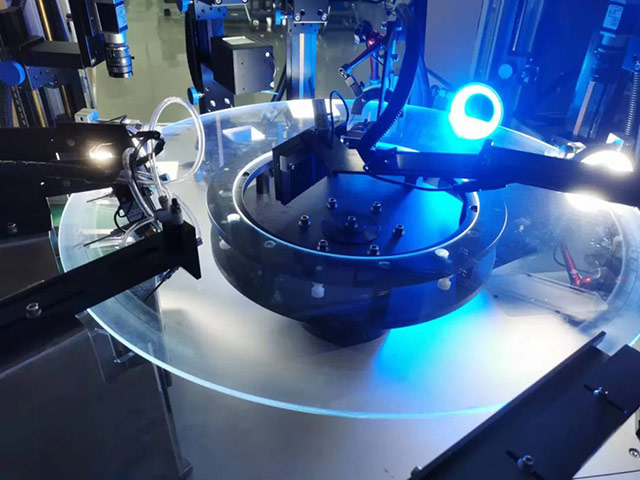

Customized Neodymium Magnets for Your Individual Projects!

We understand every customer has individual needs and specifictions for the neodymium magnets, that’s why we insit on customize for our client, not only for design but also for the manufacruring and service.

- Sizes and shapes: Neodymium magnets come in a variety of sizes and shapes to meet the diverse needs of different applications. It’s important to note that the size and shape of neodymium magnets are chosen based on the intended application, available space, and required magnetic strength.

- Grades & magnetic strength: We provide a wide range of grades:N30, N32, N33, N35, N38, N39, N40, N42, N44, N45, N48, N50, N52, N54, which is the highest grade available in current market.

- Working temperatures: Low-Temperature Grades (N35 to N45): neodymium magnets have a maximum working temperature of around 80 to 120 degrees Celsius. Medium-Temperature Grades (N48 to N50):Medium-temperature neodymium magnets can operate effectively in a temperature range of approximately 120 to 150 degrees Celsius. High-Temperature Grades (N52, N54, and higher):High-temperature neodymium magnets can operate effectively in a temperature range of 150 to 230 degrees Celsius or even higher, depending on the specific grade.

- Coatings: In addition to standard coatings such as zinc plating and NiCuNi, our offerings extend to a diverse range of specialized coatings tailored to meet varied customer needs. Our repertoire includes epoxy coatings for enhanced durability, gold and silver coatings for specific applications, as well as plastic and rubber coatings for added protection. Furthermore, we provide Teflon coatings, known for their nonstick and heat-resistant properties, as well as Parylene coatings, offering a conformal and insulating layer. This array of coatings ensures that we can cater to a wide spectrum of customer requirements, providing solutions that align precisely with specific application demands.

More Than a Neodymium Magnets Manufacturer

Advanced Material Expertise:

Beyond Neodymium, our material expertise spans a diverse range, incorporating cutting-edge alloys and composites. We harness materials with precision to craft solutions that meet the unique demands of modern applications.

Customization Prowess:

Recognizing the varied needs of industries, we offer more than off-the-shelf products. Our customization prowess allows us to tailor magnetic solutions, optimizing size, shape, and magnetic strength to align seamlessly with specific project requirements.

Innovative Design Integration:

We are not merely suppliers but collaborators in innovation. Our team works closely with clients to integrate magnetic solutions seamlessly into their designs. From automotive applications to medical devices, our magnets are seamlessly woven into the fabric of modern technological advancements.

Responsive to Industry Challenges

Adapting to the ever-evolving landscape of industry challenges, we stay at the forefront of research and development. Our commitment to staying abreast of emerging technologies ensures that our solutions remain not only current but also ahead of the curve.