| Coefficient of Thermal Expansion | 4.9 x 10-6/K |

| Theoretical Density (g/cc) | 7.2 |

| Z Ratio | 0.305 |

| Sputter | DC |

| Max Power Density* (Watts/Square Inch) |

80 |

| Type of Bond | Indium, Elastomer |

| Comments | Films very adherent. High rates possible. |

Chromium Sputtering Targets

Chromium is a steely-grey, lustrous, hard, and brittle metal that takes a high polish resists tarnishing, and has a high melting point. Chromium sputtering targets are widely used in hardware tool coating, decorative coating, and flat display coating. Hardware coating is used in various mechanical and metallurgical applications such as robot tools, turning tools, molds (casting, stamping). The film’s thickness is generally 2~10um, and the film requires high hardness, low wear, impact resistance, and resistance with thermal shock and high adhesion property. Chromium sputtering targets are commonly applied in the glass coating industry. The most important application is the preparation of automotive rearview mirrors. With the increasing requirements of automotive rearview mirrors, many companies have switched from the original aluminizing process to the vacuum sputtering chromium process.

Chromium Sputtering Targets Information

Chromium Sputtering Targets

Purity: 99.5-99.95%;

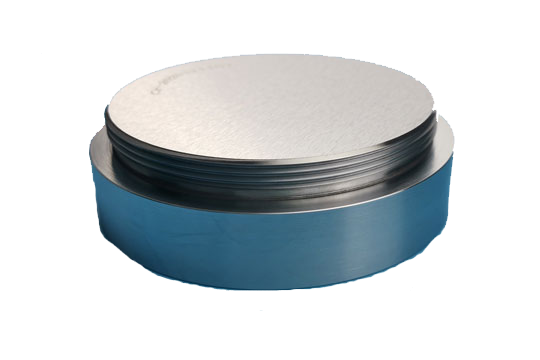

Circular: Diameter <= 14 inch, Thickness >= 1mm;

Block: Length <= 32 inch, Width <= 12 inch, Thickness >= 1mm;

Targets Type: Planar sputtering target, Rotary sputtering target, Acr cathode.

Chromium Sputtering Targets Analysis

AEM Deposition manufacture chromium sputtering targets with high purity. The highest purity can reach to 99.95%. The analytical methods we use includes:

1. Metallic elements analyze using GDMS.

2. Gas elements analyze using LECO.

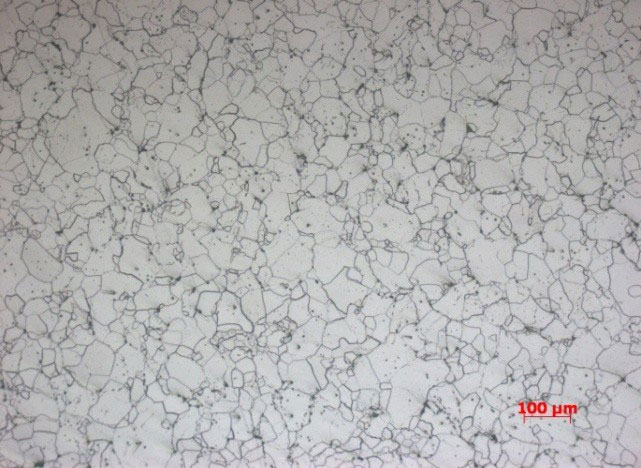

Below picture is a metallographic diagram of Chromium Sputtering Target: