[vc_row][vc_column][vc_column_text css=””]

Cemented Carbide – Tungsten Carbide Rod & Bar

Cemented Carbide is a kind of powder metallurgy product, which is mainly composed of high hardness refractory metal carbide(WC or TiC) micro powder and sintered in vacuum sintering furnace or HIP sintering furnace. The metal element cobalt (CO), nickel (Ni), molybdenum (Mo) are used as binder.

Within the field of engineering materials, tungsten carbides play a crucial role as they combine high hardness and high toughness, and they constitute the most versatile hard materials group for engineering and tooling applications. Scientists and engineers are working on adding different functional micro metals to the powder formula of cemented carbide to make this material even more powerful.

focuses its business mainly on tungsten carbide(WC) products, including tungsten carbide rod and bar. WC with binder Cobalt is the most general combination that can fulfill most applications, and Nickel can be applied to situations when the magnetism is not allowed to exist in.

| Grade | Grain Size | Co Wt % |

Density g/cm3 |

HV30 | HRA | TRS N/mm2 |

KIC Mpa•m0.5 |

|

| XN108 | K10-K20 | 0.2 | 8 | 14.46 | 2100 | 94.6 | 4500 | 10.5 |

| XU30 | K30-K40 | 0.4 | 12 | 14.1 | 1750 | 92.5 | 4000 | 15.2 |

| YF06 | K05-K10 | 0.6 | 6 | 14.9 | 1850 | 93.1 | 3800 | 9.2 |

| XF20S | K20-K30 | 0.6 | 10 | 14.37 | 1600 | 91.5 | 4000 | 15.4 |

| XF20T | K20-K30 | 0.6 | 10 | 14.45 | 1650 | 91.7 | 3800 | 15.4 |

| XF30 | K20-K30 | 0.6 | 12 | 14.15 | 1680 | 92 | 4000 | 13.2 |

| YL10A | K10-K20 | 0.8 | 8 | 14.65 | 1780 | 92.8 | 4200 | 10.7 |

| YL10.2 | K20-K30 | 0.8 | 10 | 14.42 | 1600 | 91.5 | 4000 | 14.6 |

| YL10.2S | K20-K30 | 0.8 | 10 | 14.46 | 1630 | 91.6 | 4000 | 17.5 |

| XL10 | K20-K30 | 1 | 10 | 14.4 | 1560 | 91 | 3800 | 14.9 |

| XL06H | K05-K10 | 1.2 | 6.5 | 14.85 | 1700 | 92.2 | 3600 | 11 |

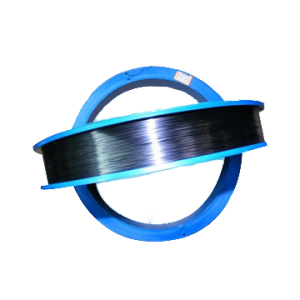

Tungsten Carbide Rods

Carbide rod of which tungsten carbide grain size ranges from 0.2micron to 0.8micron, cobalt content ranges from 6% to 12%, hardness ranges from 91.4HRA to 95HRA.

Carbide rod is the raw material to make cutting tools, such as end mills, reamers, turning tools, carbide planer cutters, carbide drills, carbide boring bar cutters, etc., for cutting or machining cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone, and ordinary steel, heat-resistant steel, stainless steel, high manganese steel, tool steel, wood, and other difficult-to-cut materials.

As one of the top tungsten carbide rod suppliers, is especially good at carbide bars for cutting difficult-to-cut materials and super hard matels.

Advantages of Cemented Carbide

-

Does not wear so quickly as it is harder

-

Resists even high temperatures

-

Application fields: wherever tools or components are exposed to high wear (e.g. when cutting hard materials)

-

Improved quality of the tools and parts

-

Longer tool life

-

Improved security

Cemented Carbide in Comparison to Other Materials

-

Diamond/PCD: hardest existing material, but characterised by high fracture toughness

-

Cemented carbide: enormous flexibility thanks to composition, can be designed either with higher toughness or higher wear resistance depending on the application. Range of applications varies extremely for cemented carbide and offers the greatest scope

-

Steel: high toughness, but low hardness

-

Ceramic: very low density, lighter than cemented carbide and heat-conducting, excellent hardness, low toughness

-

CBN: high hardness, low toughness

-

Cermet: high hardness, combines the hardness of cemented carbide and ceramic, but less tough

[/vc_column_text][/vc_column][/vc_row]