[vc_row][vc_column][vc_column_text]

Custom Titanium Parts – Machined Titanium Supplier

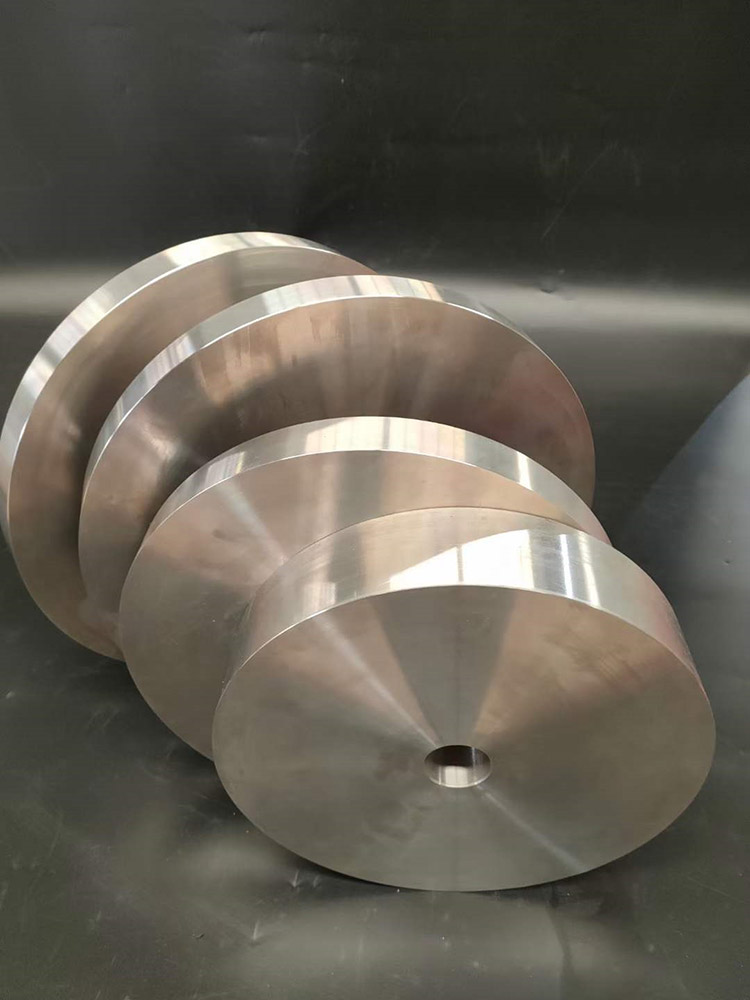

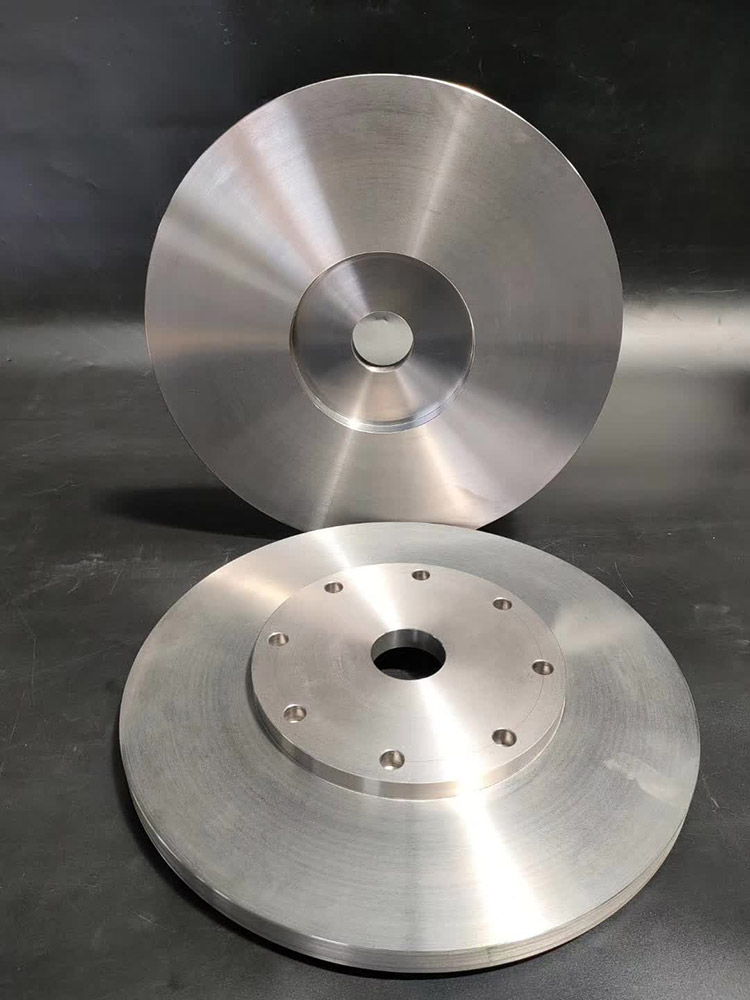

Discover excellence in titanium CNC machining with ARS Metal, where we offer a comprehensive range of services to craft custom parts in Titanium Gr.1, Gr.2, and Gr.5.

At ARS Metal, our extensive manufacturing network features a diverse array of CNC mills and turning centers. These cutting-edge facilities enable us to produce a wide spectrum of components – from straightforward ‘as-machined’ workholdings to intricate, organic geometries with strict tolerances.

Our custom titanium parts are tailored to your exact specifications, offering a level of precision that goes beyond off-the-shelf solutions. The processing scope includes but is not limited to high-precision medical in vitro diagnostic instruments, robots, intelligent equipment, analytical instruments, optical instruments, 5G equipment, petroleum equipment, new energy equipment, etc.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””]

Stock Shape include:

Plate & Sheet & Foil

Tube & Pipe

Flat Bar & Round Bar

Grade:

Pure Titanium: Gr.1, Gr.2

Titanium alloy: Gr.5, Gr.7, Gr.9

[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

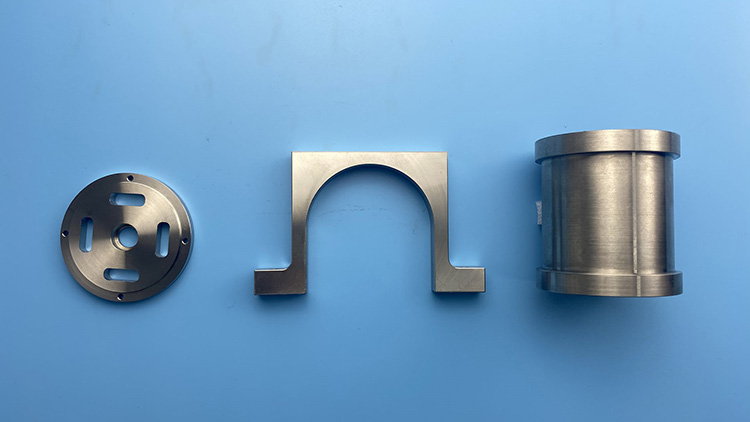

[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Custom Titanium Parts Display

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Custom Titanium Parts Display

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

Properties of Titanium

Exceptionally high strength-to-weight ratio

Corrosion resistant

Ductile

High melting point

Non-magnetic

Low thermal conductivity

Low electrical conductivity[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

Application

Aircraft/spacecraft frames and engines

Missiles and other weaponry

Hydraulic systems

Ocean-deployed surveillance devices and submarines

Gears

Compressor blades

Sporting equipment[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_empty_space][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

Fuel Injection Components

Material: Gr.5 (Ti6Al4V)

Dimensions: 85 mm x 85 mm x 50 mm

Product details: The fuel injection component is a multi-microporous product. The number of micropores can reach 189. The minimum micropore diameter accuracy can be 0.38±0.012mm. All apertures are offset in the same direction. TC4 titanium alloy is selected for CNC processing. This product has excellent corrosion resistance, high strength, good toughness and weldability.

Scope of use: used in automobile parts, motorcycle parts, mechanical parts, ship parts, petrochemical equipment, medical equipment, etc.

Processing process: milling is carried out through an intelligent 5-axis automatic machining center, using customized drill bits and anti-burr technology to ensure that the finish inside the hole is within the range of Ra1.6, flatness 0.01mm, and rotation groove angle tolerance 0.05°, and the product will turn without burrs. side.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Process of Custom Titanium Parts

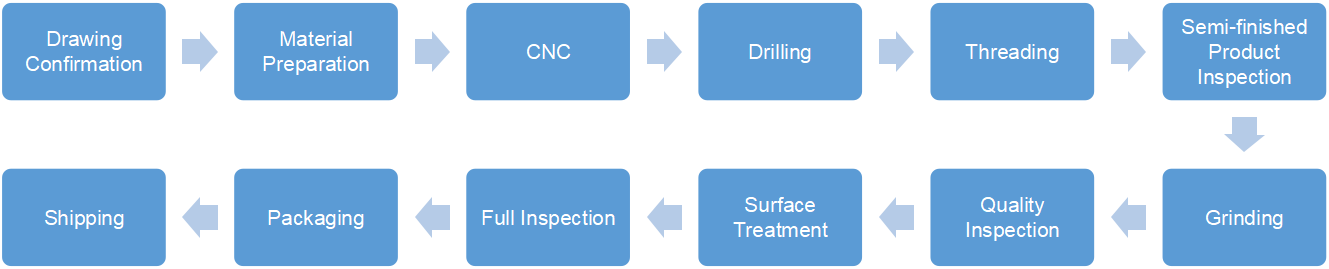

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Process of Custom Titanium Parts

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Titanium Processing Center

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Titanium Processing Center

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”” css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”” css=””]

Explore Endless Possibilities with Customization Options

Material Selection:

Choose from a range of titanium grades, including TA7 and Ti-6Al-4V, to match the specific requirements of your application.

Dimensional Precision:

Specify precise dimensions and tolerances for your custom titanium parts, ensuring a perfect fit for your project.

Surface Finishes:

Elevate the aesthetics and functionality of your components with customizable surface finishes, including polished, brushed, or coated options.

Innovative Features:

Add bespoke features such as threading, grooves, or other intricate details to meet the unique demands of your project.

[/vc_cta][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

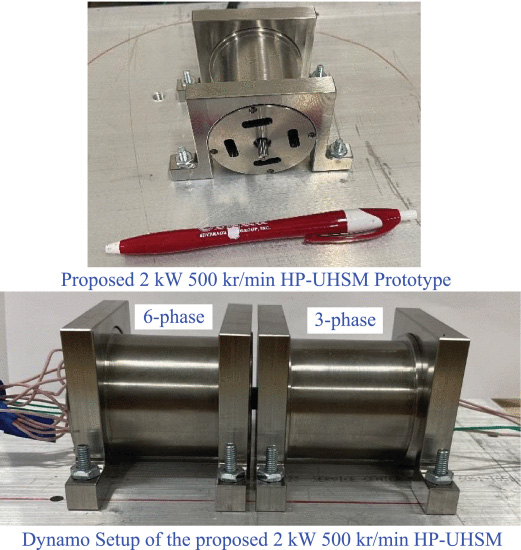

The Cooperation with Mississippi State University

ARS Metal provides the titanium alloy custom parts for “Designing High-Power Ultra-High-Speed Motor Using a New Multiphysics Multi-Objective Optimization Method for Mechanical Antenna Applications”.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”The Cooperation with King Abdullah University of Science & Technology

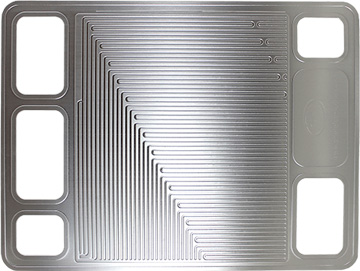

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”The Cooperation with King Abdullah University of Science & Technology

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”3/4″][vc_column_text css=””]A titanium bipolar plate substrate is usually chosen as the base metal due to its low cost, ease of manufacture into stampable bipolar plates, and its light weight.

[/vc_column_text][/vc_column][vc_column width=”3/4″][vc_column_text css=””]A titanium bipolar plate substrate is usually chosen as the base metal due to its low cost, ease of manufacture into stampable bipolar plates, and its light weight.

The cell performance of the gold-plated bipolar plates is close to and even better than the PEM fuel cells with graphite and pure titanium bipolar plates. Gold-plated titanium bipolar plates can be employed to produce fuel cells with light weight, low coating cost and low contact resistance, ideal for portable applications.[/vc_column_text][/vc_column][/vc_row]