Molybdenum Copper Alloy

MoCu alloy is a kind of pseudo-alloy that is composed of Molybdenum and Copper. It consists of Molybdenum and Copper’s characteristics, having high thermal conductivity, low thermal expansion coefficient, non-magnetic, low gas content, ideal vacuum performance, good machinability, and special high-temperature performance.

Compared with WCu alloy, MoCu alloy has a lower density and is easier to stamp. It makes MoCu suitable for volume production.

Typical MoCu Alloy Properties

| Material | Mo Content | Copper Content | Density | Thermal Conductivity at 25℃ | CTE at 25℃ |

| Wt% | Wt% | g/cm3 | W/M∙K | (10-6/K) | |

| Mo85Cu15 | 85±1 | Balance | 10 | 160-180 | 6.8 |

| Mo80Cu20 | 80±1 | Balance | 9.9 | 170-190 | 7.7 |

| Mo70Cu30 | 70±1 | Balance | 9.8 | 180-200 | 9.1 |

| Mo60Cu40 | 60±1 | Balance | 9.66 | 210-250 | 10.3 |

| Mo50Cu50 | 50±0.2 | Balance | 9.54 | 230-270 | 11.5 |

| Mo40Cu60 | 40±0.2 | Balance | 9.42 | 280-290 | 11.8 |

Cu/Mo/Cu (CMC)

Description of CMC

Cu/Mo/Cu (CMC) is a sandwich composite including a Molybdenum core layer and two copper-clad layers. It has adjustable CTE and high thermal conductivity, making it suitable for the heat sink, head frame, and microchannel cooler for PCB. All types of CMC sheets can be stamped into components.

Typical CMC Properties

| Material | Composite | Copper Content | Thermal Conductivity at 25℃ W/M∙K | CTE at 25℃ | |

| Cu:Mo:Cu | g/cm3 | In-plane | Thru-thickness | (10-6/K) | |

| CMC13:74:13 | 13:74:13 | 9.88 | 200 | 170 | 5.6 |

| CMC 141 | 1:04:01 | 9.75 | 220 | 180 | 6 |

| CMC 131 | 1:03:01 | 9.66 | 244 | 190 | 6.8 |

| CMC 121 | 1:02:01 | 9.54 | 260 | 210 | 7.8 |

| CMC 111 | 1:01:01 | 9.32 | 305 | 250 | 8.8 |

Cu/MoCu/Cu

Description of Cu/MoCu/Cu

Cu/MoCu/Cu is a sandwich composite similar to Cu/Mo/Cu, including a MoCu alloy core layer and two Copper clad layers. The normal proportion of MoCu alloy is Mo70Cu30, sometimes Mo50Cu50, and so on. The ratio of the CTE of Cu/MoCu/Cu is adjustable. It has different CTE in x, and y-direction, with higher thermal conductivity than WCu, MoCu & CMC. All types of Cu/Mo70Cu/Cu sheets can be stamped into components.

Typical Cu/MoCu/Cu Properties

| Material | Composite | Density | Thermal Conductivity at 25℃ | CTE at 25℃ | Tensile Strength |

| Cu:Mo70Cu:Cu | g/cm3 | W/M∙K | 10-6/K | MPa | |

| Cu/MoCu/Cu141 | 1:04:01 | 9.5 | 220 | 7.3/10.0/8.5 | 380 |

| Cu/MoCu/Cu232 | 2:03:02 | 9.3 | 255 | 7.5/11.0/8.5 | 350 |

| Cu/MoCu/Cu111 | 1:01:01 | 9.2 | 260 | 9.5 | 310 |

| Cu/MoCu/Cu212 | 2:01:02 | 9.1 | 300 | 11.5 | 230 |

S-CMC

S-CMC is a sandwich composite with 5 or 7 layers with better thermal conductivity and anti-distortion ability than CMC. S-CMC is also suitable for stamping.

Typical S-CMC Materials Properties

| Material | Composite | Density | Thermal Conductivity at 25℃ W/M∙K | CTE at 25℃ | |

| Cu:Mo:Cu:Mo:Cu | g/cm3 | In-plane | Thru-thickness | (10-6/K) | |

| S-CMC51515 | 5:1:5:1:5 | 9.2 | 350 | 295 | 12.8 |

| S-CMC31313 | 3:1:3:1:3 | 9.66 | ≈ | ≈ | ≈ |

| S-CMC61216 | 6:1:2:1:6 | 9.54 | ≈ | ≈ | ≈ |

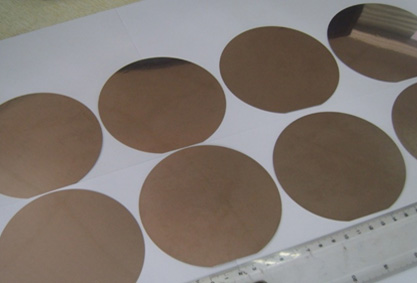

Wafer Substrates for LED Chips

With the development of LED industry in the direction of high efficiency and power, heat dissipation materials have become a top priority for solving LED thermal management problems, thereby improving performance across various lighting applications. Due to the excellent thermal conductivity and controlled thermal expansion, the molybdenum-copper and tungsten-copper alloys are the preferred heat sink materials for wafer substrates for LED packaging to reduce the overall package thermal resistance. Metal is an expert in thermal management materials made from molybdenum, tungsten, and their alloys with copper. We offer heat sink materials in mirror surfaces, as well as in plated surfaces with nickel and gold.

Wafer Substrates Typical Properties

| Type | Composition (wt%) |

Diameter (inch) |

Thickness (mm) |

Ra (um) |

Density (g/cm3) |

Thermal Conductivity (W/m∙K) |

CTE (10-6/K) |

| Pure Mo | Mo | 2, 4, 6 | 0.1~0.2±0.02 | 0.04~0.1 | 10.2 | 140 | 5.2 |

| Mo85Cu15 | Cu: 15±1 Mo: Bal. |

2, 4, 6 | 0.1~0.2±0.02 | 0.04~0.1 | 9.93±0.3 | 160-180 | 6.8 |

| Mo80Cu20 | Cu: 20±1 Mo: Bal. |

2, 4, 6 | 0.1~0.2±0.02 | 0.04~0.1 | 9.90±0.3 | 170-190 | 7.7 |

| W90Cu10 | Cu: 1O±1 W: Bal. |

2, 4, 6 | 0.1~0.2±0.02 | 0.04~0.1 | 17.0±0.3 | 180-190 | 6.5 |

| W80Cu20 | Cu: 15±1 Mo: Bal. |

2, 4, 6 | 0.1~0.2±0.02 | 0.04~0.1 | 15.6±0.3 | 200-220 | 8.2 |