[vc_row][vc_column][vc_column_text css=””]

Molybdenum Powder

A dark-gray or black lustrous powder, molybdenum was confused with graphite and lead ore before being recognized as a new element. The metal, silvery-white, is very hard but is softer and more ductile than tungsten. Molybdenum has a high melting point, good resistance to corrosion, excellent wear, and abrasion resistance, good electrical and thermal conducting properties. It is valuable for alloying, as it improves the harden-ability and toughness of quenched and tempered steels.

Molybdenum Powder Specifications

Atomic Number: 42

Molecular Weight (g/mol.): 95.94

Density, Theoretical(g/cc): 10.29

Specific Heat @20°C (cal/g-°C): 061

Melting Point (°C): 2610

Boiling Point (°C): 5560

Thermal Conductivity @100°C (cal/s-cm°C): 325

Lattice Type: Body-centered cubic

Heat of Fusion (cal/g): 70 cal/g

Heat of Combustion (cal/g): 1812

Crystallography: cubic structure, body-centered

Molybdenum Powder Grades

FMo-1, FMo-2

Molybdenum Powder Applications

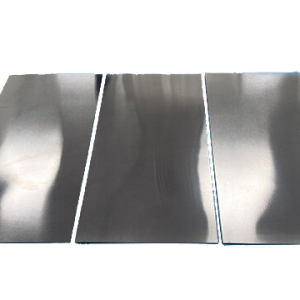

FMo-1 is used as raw material for processing the large sized molybdenum plate, an electrical heating element made of molybdenum silicide.

FMo-2 is used as raw material for processing molybdenum wafer, Molybdenum piercing mandrels

Molybdenum Powder Properties

F.S.S.S: 2.5um~6.0um

Bulk density: 0.85g/cm3~1.5g/cm3

Molybdenum Powder Package

Steel drum of 100kg or 50Kg net each lined with plastic bags

Chemical Composition of Molybdenum Powder

| Type | FMo-1 | FMo-2 | |

| Mo Content (%) ≥ | 99.9 | 99.5 | |

| Other Elements (%) < | Pb | 0.0005 | 0.0005 |

| Bi | 0.0005 | 0.0005 | |

| Sn | 0.0005 | 0.0005 | |

| Sb | 0.001 | 0.001 | |

| Cd | 0.001 | 0.001 | |

| Fe | 0.005 | 0.02 | |

| Al | 0.0015 | 0.005 | |

| Si | 0.002 | 0.005 | |

| Mg | 0.002 | 0.004 | |

| Ni | 0.003 | 0.005 | |

| Cu | 0.001 | 0.001 | |

| Ca | 0.0015 | 0.003 | |

| P | 0.001 | 0.003 | |

| C | 0.005 | 0.01 | |

| N | 0.015 | 0.02 | |

| O | 0.15 | 0.25 | |

“Mo” is the part remaining after subtracting these elements exclude a gas element from 100.

Percent by Weight

Plasma Spherical Molybdenum Powder

Application

This kind of molybdenum powder is essentially different from other granulating molybdenum powders. Spherical molybdenum powder has lower impurity contents, higher bulk density, higher tap density, narrow particle size distribution, and good fluidity. It’s an essential and irreplaceable material for spraying, near-net molding, injection molding.

Chemical Composition

O ≤ 300ppm Fe, Ni, K≤10ppm

Physical Properties

Bulk density: ≥6.0 g/cm3

Tap density: ≥6.5 g/cm3

Hall flow rate: ≤40s/50g

Rate of spheroidization: ≥98%

Monthly Output

25~45μm: 200kg/month

45~90μm: 600kg/month

90~150μm: 200kg/month

<25μm: 100kg/month

Spherical Molybdenum Powder

Application

This kind of molybdenum powder is essentially different from other granulating molybdenum powders. Spherical molybdenum powder has lower impurity contents, higher Bulk density, higher tap density, narrow particle size distribution, and good fluidity. It’s essential and irreplaceable material for spraying, near-net molding, injection molding.

Chemical Composition

O ≤ 300ppm Fe, Ni, K≤10ppm Physical Properties: Bulk density: ≥6.0 g/cm3 Tap density: ≥6.5 g/cm3 Hall flow rate: ≤40s/50g Rate of spheroidization: ≥98%

Monthly Output

25~45μm: 200kg/month

45~90μm: 600kg/month

90~150μm: 200kg/month

<25μm: 100kg/month Your special request available.

[/vc_column_text][/vc_column][/vc_row]