Your Trusted Source for N52 Neodymium magnets

Are you looking for a reliable N52 Neodymium magnets manufacturer, are you searching for the strongest magnets for your application, or even expecting design for your own specificiation, I am glad you have come to the right place.

Are you eager to explore more about us, are you ready to discuss with us, let’s start!

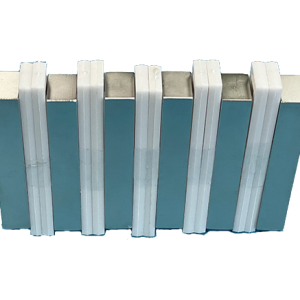

High grade N52 with diameter 10mm * 10

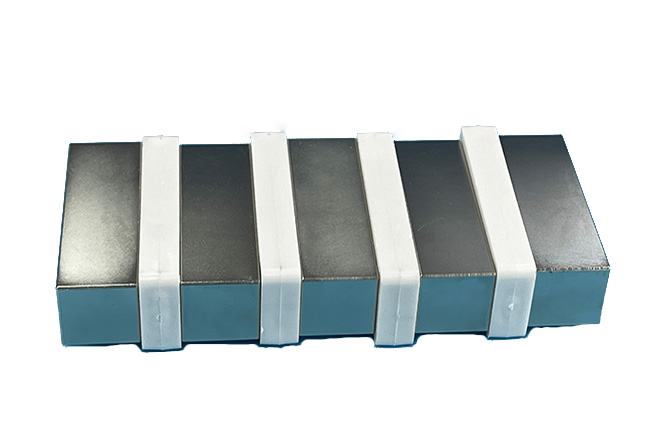

High grade N52, with size of 65*22*22

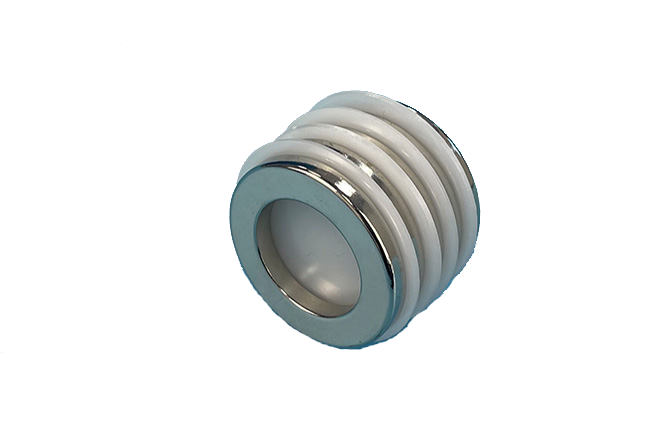

High grade N52, with size of OD 40mm * ID 25 * thickness 5mm

What are N52 Neodymium magnets?

Neodymium magnets, also known as NdFeB, NIB, or Neo magnets, are a type of rare-earth magnet made from an alloy of neodymium, iron, and boron to form the Nd2Fe14B tetragonal crystalline structure. They are the strongest type of permanent magnet commercially available, thereinto N52 is the top high grade in its category.

N52 Magnet Grade:

The “N52” designation specifically refers to the grade of the neodymium magnet. The grading system ranges from N35 to N52, with N52 being the highest, indicating a higher maximum energy product.

In the neodymium magnet grading system, the letter “N” stands for neodymium, and the number represents the maximum energy product in Mega-Gauss-Oersteds (MGOe). The higher the number, the stronger the magnet.

N52 magnets have a maximum energy product of 52 MGOe, making them one of the strongest commercially available neodymium magnets. These magnets are often chosen when a very high magnetic strength is required for a particular application.

What is the specification of N52 Neodymium magnets

What are the main applications for N52 Neodymium magnets:

Electronics: Neodymium magnets are widely used in electronic devices such as hard disk drives, headphones, and speakers due to their small size and high magnetic strength.

Motors and Generators: N52 magnets find extensive use in electric motors and generators, contributing to the efficiency and power of these devices.

Medical Devices: Neodymium magnets are utilized in various medical applications, including magnetic resonance imaging (MRI) machines and magnetic therapy devices.

Industrial Applications: N52 magnets are employed in industrial settings for tasks like metal separation in recycling plants, magnetic lifters, and in machining and manufacturing processes.

Consumer Products: These magnets are used in consumer products like magnetic clasps, closures for bags, and magnetic toys.

What are the advantages for N52 Neodymium magnets:

High Magnetic Strength: N52 magnets have an exceptionally high magnetic strength, making them suitable for applications that require a powerful magnetic field.

Compact Size: Despite their strength, neodymium magnets are relatively small and lightweight, which makes them ideal for applications where space is limited.

Cost-Effective: Neodymium magnets are cost-effective compared to other types of strong magnets, making them a popular choice for various applications.

Versatility: These magnets can be shaped into various forms, allowing for flexibility in design and application.

What should take care when use N52 Neodymium magnets:

When using N52 magnets, it’s crucial to consider these factors and follow safety guidelines to ensure proper handling and prevent accidents.

Brittleness: N52 magnets can be more brittle than lower-grade magnets, so they need to be handled with care to avoid chipping or breakage.

Corrosion: Neodymium magnets are prone to corrosion, so protective coatings are often applied to prevent degradation.

Temperature Sensitivity: Their magnetic properties can be sensitive to temperature variations, and high temperatures may cause a reduction in magnet strength.

When using N52 magnets, it’s crucial to consider these factors and follow safety guidelines to ensure proper handling and prevent accidents.

More Than a Neodymium Magnets Manufacturer

Advanced Material Expertise:

Beyond Neodymium, our material expertise spans a diverse range, incorporating cutting-edge alloys and composites. We harness materials with precision to craft solutions that meet the unique demands of modern applications.

Customization Prowess:

Recognizing the varied needs of industries, we offer more than off-the-shelf products. Our customization prowess allows us to tailor magnetic solutions, optimizing size, shape, and magnetic strength to align seamlessly with specific project requirements.

Innovative Design Integration:

We are not merely suppliers but collaborators in innovation. Our team works closely with clients to integrate magnetic solutions seamlessly into their designs. From automotive applications to medical devices, our magnets are seamlessly woven into the fabric of modern technological advancements.

Responsive to Industry Challenges

Adapting to the ever-evolving landscape of industry challenges, we stay at the forefront of research and development. Our commitment to staying abreast of emerging technologies ensures that our solutions remain not only current but also ahead of the curve.