[vc_row][vc_column][vc_column_text css=””]

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

Material TypeZ RatioSymbolSputterAtomic WeightMax Power Density*Atomic Number(Watts/Square Inch)Color/AppearanceType of BondThermal ConductivityCommentsMelting Point (°C) Coefficient of Thermal Expansion

| Niobium | 0.492 |

| Nb | DC |

| 92.90638 | 100 |

| 41 | |

| Gray, Metallic | Indium, Elastomer |

| 54 W/m.K | Attacks W source. |

| 2,468 | |

| 7.3 x 10-6/K |

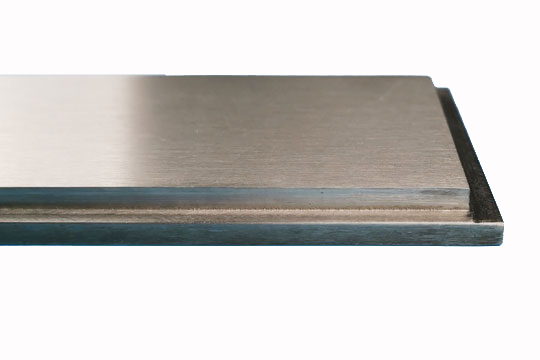

Niobium Sputtering Target

Purity: Nb>99.9%, 99.95%, 99.99%, 99.995%

Standard: ASTM B393-05

Density: >8.3g/cc

Recrystallization: >95%

Surface Roughness: Ra 0.8-1.6

Flatness: 0.1mm or 0.1%

provides niobium target with uniform, high-density microstructure, and controlled texture, promoting uniform sputtering rates and generally superior sputtering behavior.

Chemical Composition of Niobium Sputtering Target

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

GradeChemical Composition, MaxFeSiMoWTiCrTaNiOCHNNb+Ta≥%

| Nb3 | 20 | 20 | 80 | 100 | 10 | 10 | 1000 | 20 | 250 | 100 | 15 | 150 | 99.9 |

| Nb2 | 10 | 10 | 50 | 50 | 5 | 5 | 500 | 10 | 200 | 50 | 10 | 100 | 99.95 |

| Nb1 | 5 | 5 | 10 | 20 | 1 | 1 | 100 | 1 | 100 | 30 | 10 | 50 | 99.99 |

Niobium Sputtering Target Specifications

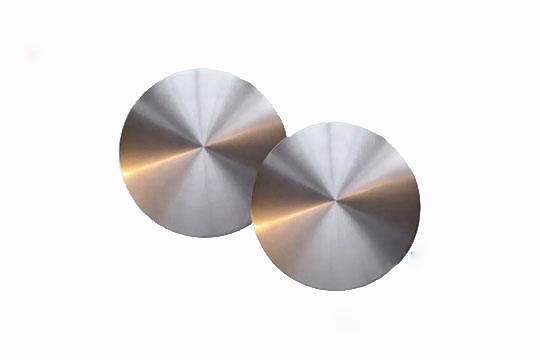

We can supply 8″, 12″ niobium round shape sputtering target. The largest disc target that we can provide is with 29” diameter. Below are most of the standard sizes for our tantalum rectangle sputtering targets. If you do not see the size that you need, please feel free to contact us.

Sizes/Tolerance(mm.max)

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

ThicknessToleranceWidthToleranceLengthToleranceGradeⅠGradeⅡ

| 3-8 | ±0.1 | ±0.2 | 50-400 | ±0.2 | 50-1800 | ±0.2 |

| 8-14 | ±0.1 | ±0.2 | 50-350 | ±0.2 | 50-1500 | ±0.2 |

| ≥14 | ±0.1 | ±0.2 | 50-300 | ±0.2 | 50-1200 | ±0.2 |

Sizes/Tolerance(mm.max)

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

| Thickness | Tolerance | Diameter | Diameter Tolerance | |

| GradeⅠ | GradeⅡ | |||

| 3-8 | ±0.1 | ±0.2 | 50-450 | ±0.2 |

| 8-14 | ±0.1 | ±0.2 | 50-450 | ±0.2 |

| ≥14 | ±0.1 | ±0.2 | 50-400 | ±0.2 |

[/vc_column_text][/vc_column][/vc_row]