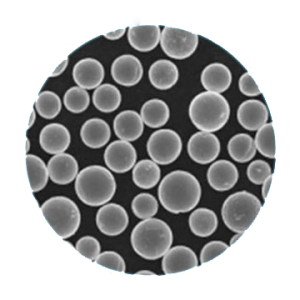

ARS provides chromium powder, manganese powder, stannum (Tin) powder, molybdenum powder, and zinc powder with different particle sizes. Chromium and Tin powder can be used for diamond carcass materials. The Manganese powder is always used in alloying element additives, and in diamond saw blades.

Molybdenum powder is a raw material widely used in molybdenum and molybdenum alloy production. Some are used for making electric heating elements, molybdenum head, and powder metallurgy materials.

The Zinc metal powder is divided into fines powder, normal powder, and superfine powder according to particle size. It is an important industrial raw material, mainly used in chemical, metallurgical, pharmaceutical, and other industries. Especially, It is used extensively in the coatings industry.

In the cold-galvanizing industry, the zinc content of zinc-rich coatings is 40%-70% of the coating’s total weight. It is widely used in the surface preservation of metal materials in seawater, freshwater, and atmospheric media, such as ships, containers, chemicals, anti-corrosion treatment of metal parts, metal parts, automobiles, motorcycles, bicycles, oil pipelines, open-air steel component towers, bridge steel structures, and highway guardrails in water conservancy projects.

Metal Powder

| Grade | Product Name | Chemical Composition (wt%) | Particle Size | Apparent Density (g/cm3) |

|---|---|---|---|---|

| O-1 | Chromium (Cr) Powder | Cr: >99.0 Other: <1.0 |

-200 mesh Customized sizes are available. |

– |

| O-2 | Sliver Powder | Al:≥ 99.0% | 0-800nm Customized sizes are available. |

– |

| O-3 | CuAg alloy Powder | Ag: Bal Cu: 18 |

– | – |

| O-4 | Manganese (Mn) Powder | Mn: >99.9 Other: <0.1 |

– | – |

| O-5 | Stannum (Sn) Powder | Sn: 99.9 Fe: ≤0.015 Pb: <0.04 S: <0.01 Cu: <0.04 |

-200 mesh | 3.3-4.3 |

| O-6 | Stannum (Sn) Powder | Sn: 99.9 Fe: ≤0.015 Pb: <0.03 S: <0.01 Cu: <0.03 |

-325mesh | 3.2-3.8 |

| O-7 | Stannum (Sn) Powder | Sn: 99.9 Fe: ≤0.015 Pb: <0.04 S: <0.01 Cu: <0.03 |

-100 mesh | 3.6-4.6 |

| O-8 | Molybedenum (Mo) Powder | Mo: > 99.5 Other: ≤0.5 |

-200 mesh Customized sizes are available. |

– |

| O-9 | Tantalum (Ta) Powder | Ta:≥ 99.9 Cu: ≤0.01 Ti: <0.03 Fe: <0.06 |

30-300 nm Customized sizes are available. |

– |

| O-10 | Spuerfines Zinc (Zn) Powder | Total Zn: ≥99 Zn metal: ≥97 Pb: <0.1 Cd: <0.05 Fe: <0.02 Acid-insoluble: <0.1 |

-1500 mesh Max: ≤10 um -1200 mesh Max: ≤12 um -1000 mesh Max: ≤13 um -800 mesh Max: ≤15 um |

– |

| O-11 | Normal Zinc (Zn) Powder | Total Zn: ≥99 Zn metal: ≥97 Pb: <0.1 Cd: <0.05 Fe: <0.02 Acid-insoluble: <0.1 |

-625 mesh Max: ≤20 um -500 mesh Max: ≤25 um -400 mesh Max: ≤38 um -325 mesh Max: ≤45 um |

– |

| O-12 | Fines Zinc (Zn) Powder | Total Zn: ≥99 Zn metal: ≥97 Pb: <0.1 Cd: <0.05 Fe: <0.02 Acid-insoluble: <0.1 |

-200 mesh Max: ≤75 um -120 mesh Max: ≤120 um -60 mesh Max: ≤250 um -40 mesh Max: ≤425 um |

– |

Oxide Ceramics powder

| Grade | Product Name | Chemical Composition (wt%) | Particle Size | Hardness | Temperature |

|---|---|---|---|---|---|

| O-13 | Yttrium oxide powder | Y2O3:≥ 99.99 | -200+325 mesh | – | – |

| O-14 | 7-8 Y2O3 zirconium powder | ZrO2+Y2O3 >98 | -200+325 mesh | HV0.3 600 | ≤ 1700℃ |

| O-15 | Chromium oxide powder | Cr2O3:≥ 98 | -200+325 mesh | HV0.3 900-1200 | ≤ 540℃ |

| O-16 | Composition powder | Cr+Al: 20 Ni+Co: 75 |

-140+325 mesh | HRC 20 | ≤ 900℃ |