[vc_row][vc_column][vc_column_text css=””]

Silver tungsten alloy, also known as tungsten silver alloy, is a combination of tungsten and silver.

It has some awesome properties! Silver gives it high conductivity, thermal conductivity, and a high melting point. On the other hand, tungsten adds high hardness, resistance to welding, minimal material transfer, and high burning resistance. These two elements come together to create a sintering material called silver tungsten.

It has some awesome properties! Silver gives it high conductivity, thermal conductivity, and a high melting point. On the other hand, tungsten adds high hardness, resistance to welding, minimal material transfer, and high burning resistance. These two elements come together to create a sintering material called silver tungsten.

But here’s the thing, silver and tungsten don’t naturally get along. So, we have to use a special method called powder metallurgy to make silver tungsten alloys. If the tungsten content is more than 60%, we use a process called infiltration. Now, the properties of these alloys depend on the ratio of silver to tungsten. If there’s more tungsten, the alloy becomes more resistant to electric arcs and wear. However, the thermal and electrical conductivity decreases.

In summary, silver tungsten alloys are a cool mix of silver and tungsten. They have some really useful properties, but their characteristics depend on how much tungsten is in the mix.

Tungsten Silver Alloy Applications

Tungsten silver alloy has many uses. It is often used to make electrodes and welding materials.

For example, it can be used in low-voltage automatic switches, high-voltage circuit breakers, and protection switches.

Specifications of Silver Tungsten Alloy

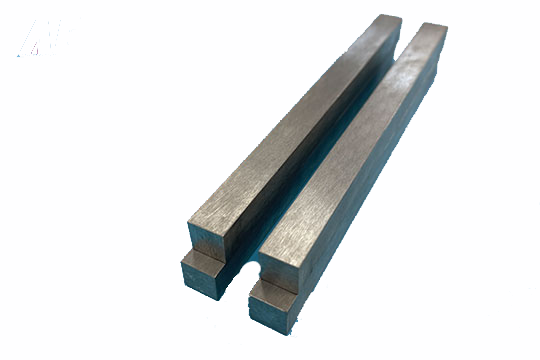

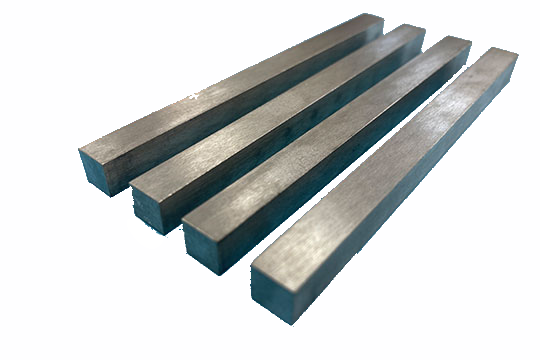

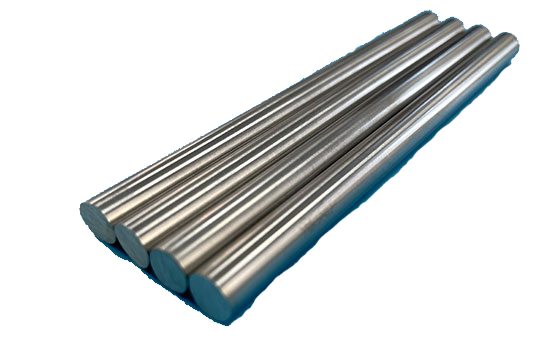

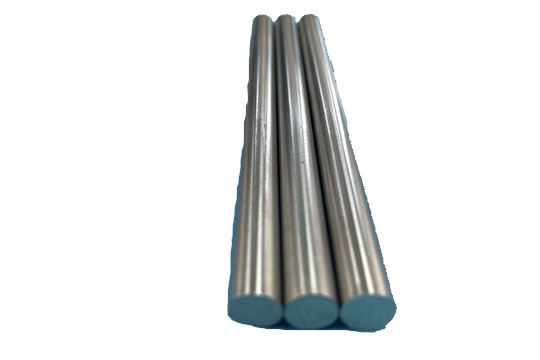

W-Ag rods, bars, sheets, plates, and tubes of different sizes.

W-Ag electrode and contact.

Silver Tungsten Alloy Properties

| Grade | Ag % |

Total Impurities % (≤) |

W % |

Density g/cm3 (≥) |

Hardness HRB (≥) |

Resistivity μΩ·cm (≤) |

Conductivity IACS/% (≥) |

Bending Strength Mpa (≥) |

| AgW30 | 70±1.5 | 0.5 | Bal. | 11.75 | 75 | 2.3 | 75 | |

| AgW40 | 60±1.5 | 0.5 | Bal. | 12.4 | 85 | 2.6 | 66 | |

| AgW50 | 50±1.5 | 0.5 | Bal. | 13.15 | 105 | 3 | 57 | |

| AgW55 | 45±1.5 | 0.5 | Bal. | 13.55 | 115 | 3.2 | 54 | |

| AgW60 | 40±1.5 | 0.5 | Bal. | 14 | 125 | 3.4 | 51 | |

| AgW65 | 35±1.5 | 0.5 | Bal. | 14.5 | 135 | 3.6 | 48 | |

| AgW70 | 30±1.5 | 0.5 | Bal. | 14.9 | 150 | 3.8 | 45 | 657 |

| AgW75 | 25±1.5 | 0.5 | Bal. | 15.4 | 165 | 4.2 | 41 | 686 |

| AgW80 | 20±1.5 | 0.5 | Bal. | 16.1 | 180 | 4.6 | 37 | 726 |

Process of Silver Tungsten Alloy

Dosing – Mixture powder – Pressing – Sintering – Polishing – Inspection.

Silver Tungsten Electrode

A silver tungsten electrode is commonly used in various industries like engines, electric power, electronics, metallurgy, spaceflight, and aviation. When exposed to air and operating current, it can develop a surface film that increases contact resistance.

In simpler terms, the electrode can form a layer on its surface that makes it harder for electricity to pass through.

Silver WC Alloy Properties

| Grade | Ag % |

WC % |

Density g/cm3 (≥) |

Conductivity IACS/% (≥) |

Hardness HRB (≥) |

| AgWC50 | 50±2 | Bal. | 12.2 | 29 | 85 |

| AgWC40 | 60±2 | Bal. | 11.7 | 34 | 75 |

| AgWC30 | 70±2 | Bal. | 11.2 | 36 | 57 |

Advantages of Silver WC Alloy

● High arc erosion resistance

● Excellent electrical conductivity

● Outstanding contact welding resistance

● Very low chopping current

Typical Silver Tungsten Alloy Products

Silver tungsten plate;

Silver tungsten bar;

Silver tungsten electrode.

Advantage of Tungsten Silver Alloy

-

High conductivity, high hardness

-

High heat conductivity

-

Wear resistance, resistance to the burning of the arc

Production Technology of Silver Tungsten Alloy

It is manufactured by a process involving pressing, sintering, and infiltrating with the silver under strictly controlled conditions. Tungsten based composites are strong refractory metal materials with superior heat, electric arc, wear and deformation resistance at high-temperature welding, flash butt, and spot welding.

They have excellent electrical and thermal conductivity. The properties of Tungsten composites vary according to the silver-to-tungsten ratio. If the tungsten content improves, the electric arc and wear resistance will increase, and on the other hand, the thermal and electrical conductivity will reduce.

[/vc_column_text][/vc_column][/vc_row]