Cobalt Powder

Cobalt powder’s three forms are reduced, electrolytic, and atomized. It’s one of the key ingredients of superhard alloy. The properties determined the bonding property, strength, and toughness of superhard alloy. It is widely used for hard alloy, diamond tools, high-temperature alloys, magnetic materials of metallurgical products, and making rechargeable batteries, industrial blasting agents, rocket fuel, and medical products.

Cobalt-based alloy powder is a hard alloy powder that can resist various wear, corrosion, and oxidation at high temperatures. It contains a considerable proportion of Cr, and W, and a small amount of Ni, Mo, Si, C, Nb, Ta elements while Co is the main ingredient. These cobalt alloy powders are used in overlayed welding, spray welding, which can also fabricate casting, and powder metallurgy components, such as high-temperature pressure valves, sawtooths, and helical rotors.

Most of our customers are alloy production companies and coating companies from all over the world. They ordered large quantities at one time. The cobalt powder supplier ARS provides high-density powders with customized sizes. If you did not find the size you need, please email us or have any queries about powders, please contact us. We will be delighted to provide help.

Cobalt Metal powder

| Grade | Product Name | Chemical Composition (wt%) | Particle Size | Apparent Density (g/cm3) | Properties |

|---|---|---|---|---|---|

| Co-1 | Cobalt Powder | Co: ≥ 99.5% Ni: 0.05 Fe: 0.01 Na: 0.015 Cu: 0.01 Zn: 0.08 Mg:0.008 C: 0.030 S: 0.03 Mn: 0.008 O: 0.50 |

≤ 2 um, -200 mesh, -300 mesh Customized sizes are available. |

0.7 – 1.0 | Lightgray, electrolytic, reduced, atomized |

Cobalt-based Alloy Powder (Thermal Sparaying and Welding Powder)

Cobalt has a hexagonal-closed-packed (hcp) crystal structure at temperatures below 417℃. Intrinsically, it has a low coefficient of friction resulting in excellent wear resistance. At temperatures above 417℃, cobalt transforms from HCP to FCC (face-centered-cubic) crystal structure, thereby generating thermal stress. Therefore, it is recommended that in weld overlaying and spraying, the parts being coated are pre-heated to 500-600℃ to avoid cracking in the coating or overlay.

Co-Cr-W

| Grade | Hardness HRC | Chemical Composition | Particle (mesh) | Application | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | W | Fe | Mo | Ni | Co | Mn | P | |||||||||||||

| Co01 | 48-54 | 2.4 | 30 | 1 | 12 | ≦3.00 | ≦1.00 | ≦3.00 | Bal. | ≦1.00 | 100/270 | Valve seats, bearing, cutting blades | ||||||||||

| Co03 | 48-54 | 2.3 | 30 | 1 | 12 | ≦3.00 | / | ≦3.00 | Bal. | / | 100/270 | Needle valve seats, guide roils valve seats | ||||||||||

| Co06 | 38-44 | 1.2 | 30 | 1 | 4.5 | ≦3.00 | ≦3.00 | Bal. | ≦1.00 | 100/270、300/500 | Engine values, high temperature pressure valves, turbo engine blades | |||||||||||

| Co156 | 40-45 | 1.6 | 28 | 1.1 | 4 | Bal. | 100/270 | Automotive partis, military application | ||||||||||||||

| Co06H | 43-48 | 1.3 | 30 | 1.5 | 5.5 | 3.00Max | 0.8 | 3.00Max | Bal. | 1.0Max | 100/270 | Engine values, high temperature pressure valves, turbo engine blades | ||||||||||

| Co12 | 42-48 | 1.4 | 29 | 1.4 | 8.5 | ≦3.00 | ≦1.00 | ≦3.00 | Bal. | ≦1.00 | 100/270 | High temperature pressure valves, turbo engine blades | ||||||||||

| Co12B | 45-49 | 1.3 | 30 | 1 | 5.5 | 3.0Max | 5 | 10.5 | Bal. | 1.0Max | 100/270 | Saw, guide plates | ||||||||||

| Co12H | 48-53 | 1.7 | 30 | 1.7 | 7 | 2.0Max | 2 | 3.0Max | Bal. | 0.5Max | 100/270 | High temperature pressure valves, saw teeth, extrusion screws | ||||||||||

| Co6113 | 43-48 | 1.8 | 27 | 4 | 6 | Bal. | 100/270 | Resistance to corrosion and wear | ||||||||||||||

| Co107 | 40-44(46-50) | 2 | 35 | 1 | 5 | 2.0Max | 24 | Bal. | 1 | 100/270 | Work hardening | |||||||||||

| Co19 | 48-56 | 1.8 | 31 | 1 | 11 | 3.0Max | 3.0Max | Bal. | 1 | 100/270 | Cutting knives | |||||||||||

| CoF | 37-44 | 1.6 | 26 | 1.1 | 12 | 3.0max | 0.5Max | 22.5 | Bal. | 0.5Max | 100/270 | Engine values | ||||||||||

| CoFH | 38-44 | 1.4 | 28 | 1.2 | 12 | 3.0Max | 0.8 | 22.5 | Bal. | 0.5 | 100/270 | Engine values | ||||||||||

| Co20 | 47-53 | 2.5 | 32 | 1 | 18 | ≦3.00 | ≦1.00 | ≦3.00 | Bal. | ≦1.00 | 300/500 | Bearing sleeves, wear plates | ||||||||||

| Co07 | 30-36 | 0.4 | 26 | 0.9 | 5.5 | 3.0Max | 3.0Max | Bal. | 0.3 | 100/270 | Steam turbine blades, brass casting molds, extrusion molds | |||||||||||

| CoX-40 | 30-35 | 0.8 | 25.5 | 0.4 | 7.5 | 1.0Max | 1.0Max | 10.5 | Bal. | 0.5Max | 0.04Max | 100/270 | Steam turbine pans for resisting high temperature degradation and erosion | |||||||||

| Co31 | 30-35 | 0.4 | 25.5 | 0.8 | 7.5 | 2.0Max | 0.5Max | 10.5 | Bal. | 0.5Max | 100/270 | Steam turbine pans for resisting high temperature degradation and erosion | ||||||||||

| Co694 | 47-53 | 1 | 28 | 1 | 19 | 2.5Max | Bal. | 1 | 100/270 | Steam turbine parts for resisting temperature degradation and erosion | ||||||||||||

| Co25 | 20Max | 0.05Max | 20 | 0.8 | 15 | 3.0Max | 8 | 10 | Bal. | 1.3 | 100/270 | Hot extrusion molds | ||||||||||

| Co306 | 34-40 | 0.4 | 25 | 1 | 2.5 | 4.0Max | 6 | Bal. | 1 | 100/270 | Steel hot rolling shears, clangs, guide rolls | |||||||||||

| Co238 | 20-26 | 0.1 | 26 | 1 | 20 | 3 | Bal. | 1 | 100/270 | Forging dies | ||||||||||||

| Co190 | 57-63 | 3.3 | 26 | 0.8 | 14 | 3.0Max | 1.0Max | 3.0Max | Bal. | 1.0Max | 100/270 | Oil drilling heads | ||||||||||

| Co400 | 48-54 | 0.08Max | 8.5 | 2.5 | 2.0Max | 29 | 1.0Max | Bal. | 0.5Max | 100/270、300/500 | Galvanizing line bearing sleeves and shaft sleeves | |||||||||||

| Co400M1 | 50-54 | 0.08Max | 14 | 2.6 | 0.5Max | 26 | 0.5 | Bal. | 0.1Max | 100/270、300/500 | Resist high-temperature corrosion, galvanizing bearing sleeves, shaft sleeves | |||||||||||

| Co400M2 | 46-52 | 0.08Max | 17 | 1.2 | 0.5Max | 22 | 0.5Max | Bal. | 0.5Max | 100/270、300/500 | Resist high temperature corrosion, galvanizing bearing sleeves, shaft sleeves, natural gas engine valves | |||||||||||

| Co800 | 52-58 | 0.08Max | 17.5 | 3.5 | 2.0Max | 29 | 1.0Max | Bal. | 0.5Max | 300/500 | Resist high temperature degradation | |||||||||||

Co-Cr-Mo

| Grade | Hardness (HRC) | Chemical Composition | Particle (mesh) | Application | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | Fe | Mo | Ni | Co | Mn | |||||||||||

| Co706 | 38-43 | 1.2 | 29 | 0.5 | 3.0Max | 5 | 3.0Max | Bal. | 1 | 100/270、300/500 | Pressure valves with high temperature corrosion resistance | |||||||

| Co712 | 45-50 | 1.8 | 29 | 0.5 | 3.0Max | 9 | 3.0Max | Bal. | 0.5 | 100/270 | Pressure valves with high temperature corrosion resistance, ectrusion screws | |||||||

| Co701 | 50-56 | 2.5 | 31 | 0.5 | 3.0Max | 13 | 3.0Max | Bal. | 0.5 | 100/270 | Pressure valves with high temperature corrosion resistance, ectrusion screws | |||||||

| Co720 | 54-60 | 2.5 | 33 | 0.5 | 3.0Max | 18 | 3.0Max | Bal. | 0.8 | 300/500 | Pressure valves with high temperature corrosion resistance | |||||||

| Co721 | 18-24 | 0.05Max | 30 | 0.6 | 8 | 4 | 0.3Max | Bal. | 0.7 | 100/270 | Steam turbine erosion-resistant parts | |||||||

Self-fusing Cobalt Base Alloy Powder

| Grade | Hardness (HRC) | Chemical Composition | Particle (mesh) | Application | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | W | Fe | Mo | Ni | Co | Mn | B | |||||||

| Co157 | 51-57 | 0.3 | 22 | 1.5 | 5 | 3.0Max | 3.0Max | Bal. | 2.4 | 150/300 | High temperature pressure valves | |||||

| Co158 | 40-46 | 0.8 | 29 | 1.5 | 5.5 | 3.0Max | ≦1.00 | ≦3.00 | Bal. | ≦1.00 | 0.8 | 150/300 | High temperature pressure valves | |||

| Co158V | 45-50 | 1 | 30 | 1.2 | 8 | 3.0Max | 3 | Bal. | 0.3Max | 0.8 | 200/400 | Motorcycle engine valves | ||||

| CoWC35 | 57-63 | 2.4 | 12 | 2.6 | 33 | 3.0Max | 9 | Bal. | 1.9 | 150/300 | Motorcycle engine valves | |||||

| CoSF6 | 40-46 | 0.6 | 18 | 2.3 | 7.5 | 3.0Max | 1.0Max | 14 | Bal. | 0.5Max | 1.7 | 150/300 | Galvanizing line bearing and shaft sleeves | |||

| CoSF12 | 46-52 | 0.9 | 18 | 2.8 | 9 | 3.0Max | 14 | Bal. | 0.5Max | 1.8 | 150/300 | High temperature pressure valves and seats | ||||

| CoSF1 | 52-58 | 1.2 | 19 | 2.8 | 12 | 3.0Max | 12 | Bal. | 0.5Max | 2.4 | 150/300 | High temperature pressure valves and seats | ||||

| CoSF20 | 59-64 | 1.5 | 19 | 3 | 15 | 2.0Max | 13 | Bal. | 0.5Max | 3 | 150/300 | High temperature pressure valves and seats | ||||

| CoSFT400 | 55-60 | 0.1 | 10 | 2.5 | 1.0Max | 22 | 5 | Bal. | 0.5Max | 1.8 | 100/270 | Galvanizing line bearing shaft sleeves | ||||

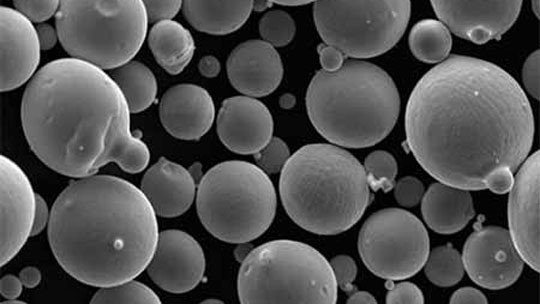

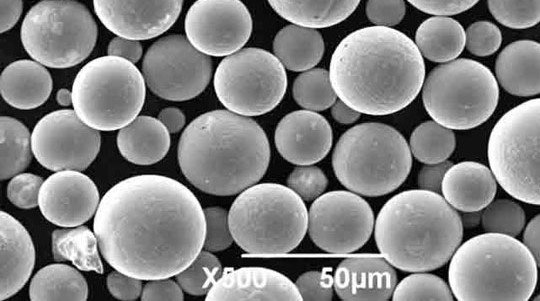

Spherical Cobalt Based Alloy Powder

Spherical Cobalt Based Alloy Powder

Cobalt-based alloy powder is hard alloy powder that can resist various wear, corrosion, and oxidation at high-temperature. It contains a considerable proportion of Cr and W, and a small amount of Ni, Mo, Si, C, Nb, Ta elements and Co is the main ingredient. These cobalt alloy powders are used in overlayed welding, spray welding, which can also fabricate casting, and powder metallurgy components, such as high-temperature pressure valve, sawtooths, and helical rotor.

Chemical Composition of Cobalt-based Alloy Powder

| Chemical Composition (wt%) |

Grade | |||||

|---|---|---|---|---|---|---|

| CoCrMo | CoCrMoW | GH5188 | GH5605 | GH5941 | ||

| Cr | 26-30 | 23.7-25.7 | 20-24 | 19-21 | 19-23 | |

| Mo | 5-7 | 4.6-5.6 | ||||

| Si | ≤1 | 0.8-1.2 | ||||

| Mn | ≤1 | |||||

| Fe | ≤0.75 | ≤0.5 | ≤3 | ≤3 | ≤1.5 | |

| Ni | ≤0.5 | 20-24 | 9-11 | 19-23 | ||

| Co | Bal. | Bal. | Bal. | Bal. | Bal. | |

| W | ≤0.5 | 4.9-5.9 | 13-16 | 14-16 | 17-19 | |

| C | ≤0.16 | 0.05-0.15 | 0.05-0.15 | ≤0.1 | ||

| Al | ≤0.1 | |||||

| Ti | ≤0.1 | |||||

| P | ≤0.02 | |||||

| S | ≤0.01 | |||||

| B | ≤0.01 | |||||

| O | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | |

| N | 0.13-0.25 | 0.13-0.25 | 0.13-0.25 | |||

| Ta | ≤0.05 | ≤0.05 | ≤0.05 | |||