Tungsten Powder

ARS provides tungsten powder and tungsten carbide powders in high quality with great density. Please contact us if you don’t find the powders you need. The powder sizes can be customized as per customers’ demands.

Tungsten Powder Features

Application: Tungsten powder is widely used to produce weight fillers, radiation shielding fillers, and induction accelerators. The thin film surface of its polymer mixture is ideally suitable for radiation protection. The large particle size makes it an ideal heavy metal filler for injection-molding applications. The unique shape and the resulting high flowability of the particles make it suitable for the metal spray industry applications. Another vital application of Tungsten powder is made of Tungsten Carbide powder and preparation of cemented carbide tools, such as turning, milling, drilling, and molds.

Chemical Composition of Tungsten Powder

| Chemical Composition | FW-1 | FW-2 | FW-3 | |

|---|---|---|---|---|

| W Content (%)≥ | 99.95 | 99.8 | 99.8 | |

| Other Elements (%) < | Fe | 0.005 | 0.03 | 0.03 |

| Al | 0.001 | 0.004 | 0.005 | |

| Mg | 0.002 | 0.005 | 0.01 | |

| Mn | 0.001 | 0.004 | 0.004 | |

| Ni | 0.001 | 0.002 | 0.004 | |

| As | 0.003 | 0.004 | 0.005 | |

| Pb | 0.0015 | 0.002 | 0.002 | |

| Bi | 0.0001 | 0.0005 | 0.0007 | |

| Sn | 0.0001 | 0.0005 | 0.0007 | |

| Sb | 0.0003 | 0.0005 | 0.0007 | |

| Cu | 0.0001 | 0.001 | 0.001 | |

| Ca | 0.0007 | 0.001 | 0.002 | |

| Mo | 0.002 | 0.002 | 0.004 | |

| K+Na | 0.005 | 0.005 | 0.01 | |

| P | 0.003 | 0.009 | 0.003 | |

| C | 0.005 | 0.004 | 0.004 | |

| O | 0.005 | 0.01 | 0.01 | |

| Special requirements to be agreed upon by the supplier and buyer | ||||

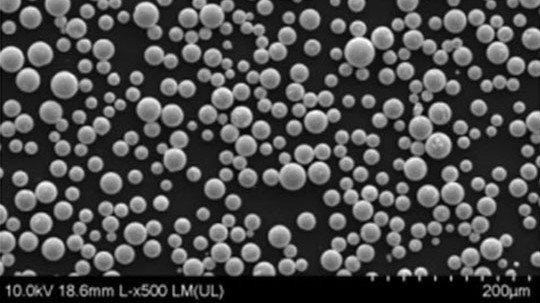

Spherical Tungsten Powder

Physical Properties of Spherical Tungsten Powder

| Size | 15-53 um | ||||

|---|---|---|---|---|---|

| Apparet Density | 10.51 g/cm3 | ||||

| Tap Density | 12.46 g/cm3 | ||||

| Hall Flow Rate | 5.82 s/50g |

Chemical Composition of Spherical Tungsten Powder

| Chemical Composition – by ICP-AES | ||||||||

|---|---|---|---|---|---|---|---|---|

| Element | W | Al | Si | Mg | Mn | Ni | As | Pb |

| Value (%) | ≥99.9 | <0.002 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Element | Sn | Sb | Cu | Ca | Mo | K+Na | ||

| Value (%) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | ||

| Gas Impurities | ||||||||

| Element | C | P | O | N | ||||

| Value (%) | 0.002 | 0.001 | 0.015 | 0.003 | ||||