[vc_row][vc_column][vc_column_text]

Discover ARS METAL Tantalum Bars: Strong and Reliable

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Our Product Specifications

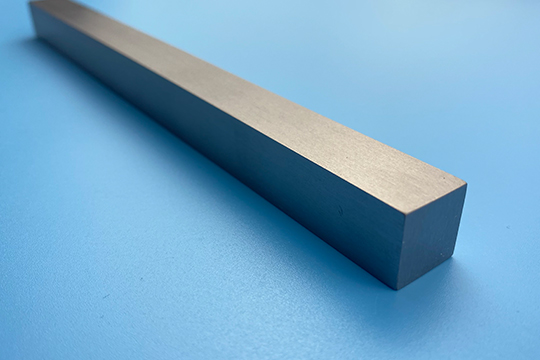

Our tantalum round bars are crafted to suit your needs. You can choose from a variety of lengths, either as random-sized pieces or cut to the specific length you need. The diameter of these bars ranges from a slim 0.125 inches up to a substantial 5.00 inches.

Grade: R05200, R05400, R05252(Ta-2.5W), R05255(Ta-10W)

Standard: ASTM B365-98

Purity: Ta >99.95% or >99.99%

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Here, you can find a list of our standard tantalum round bar sizes. We also have a range of standard sizes for our tantalum rectangular bars.

Can’t find the size you’re looking for? No problem! Just get in touch with us, and we’ll help you customize the right size for your project.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

| Width | Thickness | Length | Length Tolerance |

| 15mm | 15mm | 600mm | +1mm, -0 |

| 20mm | 20mm | 1000mm | +1mm, -0 |

| 45mm | 45mm | 1200mm | +2mm, -0 |

| 60mm | 60mm | 1500mm | +3mm, -0 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Chemical Composition of Tantalum Bar

| Grade | TTa-01 | TTa-02 | TTa-1 | TTa-2 | |

| Impurity Content ,%,Max |

C | 0.004 | 0.006 | 0.015 | 0.02 |

| O | 0.01 | 0.03 | 0.15 | 0.15 | |

| N | 0.003 | 0.01 | 0.008 | 0.01 | |

| Cr | 0.005 | – | 0.005 | 0.01 | |

| Nb | 0.005 | 0.1 | 0.01 | 0.02 | |

| Fe | 0.005 | 0.01 | 0.005 | 0.01 | |

| W | 0.002 | 0.05 | 0.003 | 0.005 | |

| Mo | 0.001 | 0.02 | 0.003 | 0.005 | |

| Si | 0.002 | 0.025 | 0.003 | 0.015 | |

| Ni | 0.005 | 0.01 | 0.01 | 0.01 | |

| Ta | Balance | Balance | Balance | Balance | |

| Size | Φ(15-26)×(100-500) | (12-17)×(12-17)×(100-400) | |||

| Density(g/cm3) | ≥15.6 | – | |||

| Application | For materials to processed | For superalloys and electron beam melting | |||

[/vc_column_text][vc_custom_heading text=”Custom-Made Tantalum Bars for Your Specific Needs

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

Tailoring to Unique Requirements

Every industry has unique needs. We provide custom solutions of tantalum bar to meet specific demands. This includes varying sizes, shapes, and compositions. Our team works closely with clients. We understand their specific applications and requirements. This ensures the final product meets their precise needs.

Meeting Industry-Specific Standards

Different industries have specific standards. Our custom-made tantalum bars meet these standards. We serve industries like aerospace, medical, and electronics. We ensure our products comply with industry regulations. This includes standards for purity, strength, and durability.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Our Tantalum Bars Advantages

At ARS METAL, we understand the critical role our tantalum bars play in a myriad of industrial applications. That’s why we’ve dedicated ourselves to not only meeting but surpassing industry standards. Here’s how our tantalum bars stand out:

Exceptional Purity Levels:

Our tantalum bars boast an impressive purity of up to 99.97%, ensuring top-tier quality and performance in every application.

Optimized Density:

We achieve a density of up to 99.5% in our tantalum bars, providing enhanced durability and reliability in demanding environments.

Precision in Production:

We follow rigorous standards in our production, ensuring every tantalum bar we make performs reliably and precisely.

Customized Solutions:

Understanding our clients’ varied demands, we focus on creating tantalum bars that are specifically suited to your unique applications.

Tailored Dimensions:

Beyond our standard range, we offer tailor-made sizes to perfectly fit your specific requirements.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”What Tantalum Bar is Used for

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””]

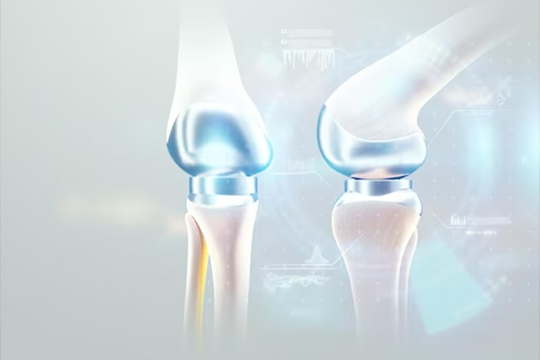

Medical Technology Uses

The biocompatibility of tantalum makes it perfect for medical technology. It’s used in surgical instruments and implants. Its corrosion resistance ensures safety and longevity inside the human body.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

Aerospace Components

Jet Engine Parts: In aerospace, tantalum bars are used for parts that require heat resistance. Spacecraft Construction: Their strength and durability are crucial in extreme space conditions.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

Laboratory Equipment

Tantalum bars are essential in laboratory settings. They are used in various equipment due to their resilience. Their chemical resistance makes them ideal for lab use. They handle reactive substances without degrading.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

Machined Fasteners

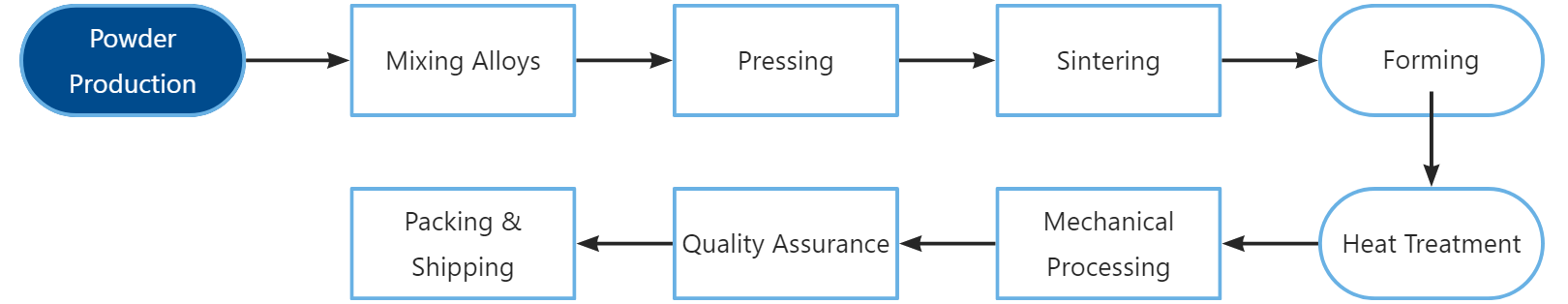

Tantalum machined fasteners have high corrosion tolerance. They replace fasteners made of less durable materials. These are used in mining, energy, pharmaceuticals, metal, and chemical manufacturing. They prevent malfunctions and costly repairs.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Manufacturing Processes for Tantalum Bar (Powder Metallurgy)

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

Advanced Powder Production

ARS Metal uses advanced chemical reduction to create ultra-pure, uniform metal powders. This process is key for high-quality metal products.

Mixing Alloys

Our alloy mixing process is characterized by meticulous precision. This creates alloys with unmatched performance and reliability.

Precision Pressing and Shaping

Using state-of-the-art pressing techniques, we mold our metal powders into desired shapes. Our technology excels in producing complex geometries with high precision.

Cutting-Edge Sintering Process

Our sintering process employs advanced technology. It bonds powder grains effectively, creating dense and robust sinter blocks. This step is crucial for the durability of our products.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Forming for Enhanced Durability

We use unique forming methods to increase material density and strength. Our process ensures our tantalum bars can withstand rigorous applications.

Specialized Heat Treatment

Our heat treatment process is tailored to each product. It fine-tunes the mechanical properties of the metal, ensuring ease of subsequent processing and optimal performance.

Precision Mechanical Processing

ARS Metal offers specialized mechanical processing. Our services include turning, milling, grinding, cutting, joining, and coating. We focus on precision and quality in every step.

Final Product Inspection

Inspect the final Tantalum bar, including dimensional measurements, surface inspection, chemical composition analysis, etc. This ensures that the final product meets specifications.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Your Comprehensive Guide to Purchasing Tantalum Bars

What is Tantalum Bar? A Brief Overview

Tantalum bars are solid, long pieces of tantalum metal. Tantalum is a rare, highly durable, and corrosion-resistant material. It is used in various industries for its exceptional properties. Tantalum bars are typically used in manufacturing, electronics, and aerospace industries. They are chosen for their strength, malleability, and resistance to corrosion and high temperatures.

Unique Properties of Tantalum Bar

Tantalum bars are known for several unique properties:

High Melting Point:

They can withstand extremely high temperatures. They have a melting point over 3000°C, making them ideal for high-heat environments.

Corrosion Resistance:

Tantalum bars resist corrosion, even when exposed to strong acids.

Ductility:

Despite their strength, they are highly malleable, allowing them to be formed into various shapes without breaking.

Conductivity:

They conduct electricity well, which is essential in electronic applications.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Grades of Tantalum Bar

When selecting tantalum bars, understanding the various grades and their specific applications is crucial.

Below is a detailed overview of the main tantalum bar grades, presented in a uniform format for clarity:

| Grade | Description | Primary Applications |

|---|---|---|

| R05200 | Unalloyed tantalum. Known for its high purity and excellent corrosion resistance. | Chemical processing equipment, high-temperature furnace parts, and heat exchangers. |

| R05400 | Unalloyed tantalum, similar to R05200, but with slight variations in processing and properties. | Chemical and aerospace industries |

| R05255(Ta-10W) | Alloy containing 90% tantalum and 10% tungsten. Offers enhanced strength and higher melting point. | Suitable for aerospace and missile parts, and applications requiring higher strength and thermal stability. |

| R05252(Ta-2.5W) | Comprises 97.5% tantalum and 2.5% tungsten. known for durability. | Surgical implants and instruments, as well as electronic components. |

| R05240(Ta-40Nb) | A blend of 60% tantalum and 40% niobium, this alloy offers excellent corrosion resistance and physical properties. | Frequently used in superconducting magnets, nuclear reactors, and missile parts. |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Important Factors to Consider When Buying a Tantalum Bar

Check Quality and Purity

Understand the Grade and Composition

Size and Shape

Needs for Your Specific Use

Reliable Suppliers

Budgeting

[/vc_column_text][/vc_column][/vc_row]