[vc_row][vc_column][vc_column_text css=””]

Tantalum Carbide Powder: Elevating Industrial Performance

Tantalum Carbide Powder is a cutting-edge industrial material known for its exceptional qualities and ability to boost performance. At ARS Metal, we are dedicated to crafting high-quality Tantalum Carbide Powder. Our product is designed to meet the diverse needs of various industries. We prioritize creating a powder that is not only of superior quality but also highly functional and effective.

What makes our Tantalum Carbide Powder unique? It’s the meticulous attention to detail in our manufacturing process, paired with rigorous quality control. This results in a product that is not only reliable but also superior in performance.

Our Tantalum Carbide Powder is durable, efficient, and versatile. It offers clear advantages over traditional materials, making it a smart choice for various industries. It is often used as a fine-crystalline additive to tungsten carbide alloys. Whether you need a standard solution or a custom formulation, we can cater to your specific requirements.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Carbide Powder Specifications

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Carbide Powder Specifications

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

| Formula: | TaC192.96 |

| Purity: | 99.0% to 99.9% |

| Particle Size: | 0.5-5 Micron (customizable) |

| CAS Number: | CAS-12070-06-3 |

| Grade: | FTaC-1, FTaC-2 |

| Appearance: | Brown to black powder |

| Melting Point: | 3880°C / 7016°F |

| Boiling Point: | 5500°C / 9932°F |

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Compositions of Tantalum Carbide Powder

| Grade | FTaC-1 | FTaC-2 | ||

| Grade | Na(Nb)C | ≥99.5 | ≥99.0 | |

| T.C | ≥6.20 | ≥6.20 | ||

| F.C | ≤0.1 | ≤0.15 | ||

| Impurity Content ,%,Max | Nb | 0.3 | 1 | |

| Fe | 0.05 | 0.1 | ||

| Si | 0.008 | 0.01 | ||

| Al | 0.005 | 0.005 | ||

| Ti | 0.0085 | 0.015 | ||

| O | 1 | 0.35 | 0.35 | |

| 2 | 0.3 | 0.3 | ||

| 3 | 0.2 | 0.2 | ||

| 4 | 0.15 | 0.15 | ||

| N | 0.025 | 0.05 | ||

| Na | 0.005 | 0.008 | ||

| Ca | 0.005 | 0.008 | ||

| Mn | – | – | ||

| Fsss(μm) | 1 | 0.8-1.0 | ||

| 3 | 1.0-1.2 | |||

| 3 | 1.2-1.5 | |||

| 4 | 1.5-3.0 | |||

[/vc_column_text][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Carbide Applications

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]Tantalum carbide stands out in the materials world. Its remarkable hardness and incredible thermal properties don’t just make it popular; they make it essential in a variety of industries. Here, we explore its main applications.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

Enhanced Cemented Carbide

Tantalum carbide boosts the quality of cemented carbide. It makes these alloys stronger, more stable, and easier to work with by improving their internal structure.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

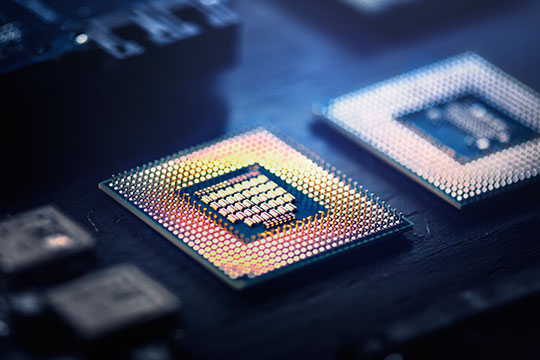

Semiconductor Industry

Tantalum Carbide (TaC) nano-materials are promising in the semiconductor industry. Use in thin film coatings, heat dissipation components, and integrated circuits (ICs).[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

High-temperature Alloy

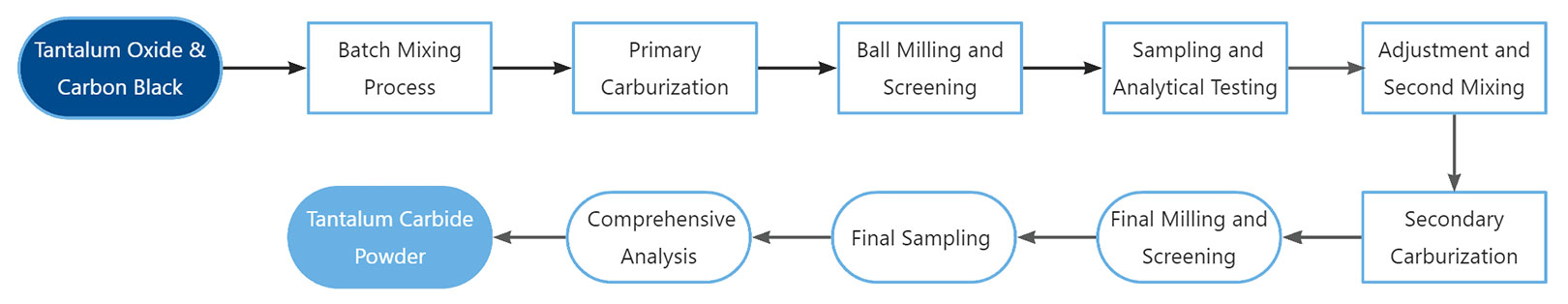

Tantalum carbide is very strong at high temperatures, much more than top-quality polycrystalline graphite. It’s the only material that stays strong between 2900℃ and 3200℃.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Manufacturing Processes for Tantalum Carbide Powder (Reduction Method)

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

-

Preparation of Raw Materials:

-

Batch Mixing Process:

-

Primary Carburization:

-

Ball Milling and Screening:

-

Sampling and Analytical Testing:

-

Adjustment and Second Mixing:

-

Secondary Carburization under Vacuum:

-

Final Milling and Screening:

-

Final Sampling and Comprehensive Analysis:

-

Preparation of Tantalum Carbide Powder:

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Carbide Powder: A Comprehensive Guide for Buyer

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

What is Tantalum Carbide Powder? A Brief Overview

Tantalum carbide is a light brown powder that looks like metal and has tiny, evenly-sized particles. It’s strong, heavy, and has great chemical stability. It works well at high temperatures and is good at conducting electricity.

Tantalum carbide powder is a significant type of metal-ceramic material. Tools crafted from this material can endure high temperatures, up to 3800 degrees, and are as hard as diamonds. When used as a grain refiner in tungsten-based hard alloys, it notably enhances the alloy’s capabilities.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

Unique Properties of Tantalum Carbide Powder

Tantalum Carbide Powder is known for its distinct and valuable properties. Its unique features make it a preferred material in various industries. Below is a detailed look at its key properties:

Exceptional Hardness:

Tantalum Carbide is one of the hardest materials known, ranking just below diamond. This extreme hardness is crucial for manufacturing robust cutting and drilling tools, ensuring durability and efficiency in high-wear scenarios.

High Melting Point:

It has an extraordinary melting point, over 3,000 degrees Celsius. This quality allows Tantalum Carbide to perform reliably in environments with extreme heat, aking it vital in aerospace engineering and military equipment.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Chemical Resistance:

This powder is highly resistant to chemical corrosion. It maintains stability and retains its properties even in harsh chemical environments, not reacting significantly with most acids and alkalis.

Electrical and Thermal Conductivity:

Tantalum Carbide stands out for its excellent electrical conductivity, playing a significant role in electronic applications. Its ability to efficiently conduct electricity is crucial for various electronic devices.

Tantalum Carbide Powder VS Tungsten Carbide Powder

Tantalum Carbide (TaC) and Tungsten Carbide (WC) powders are key materials in advanced industries. Both are known for their hardness and durability. Yet, they have distinct qualities and uses. Let’s explore their differences in a simplified manner:[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

| Feature | Tantalum Carbide (TaC) Overview | Tungsten Carbide (WC) Overview |

|---|---|---|

| Composition | Made of tantalum and carbon, TaC is known for stability and thermal shock resistance. | A blend of tungsten and carbon, WC is recognized for its extreme hardness and wear resistance. |

| Hardness | Very hard, slightly less than WC, suitable for durable applications. | One of the hardest materials, ideal for high-wear industrial applications. |

| Thermal Properties | With a melting point over 3,800°C, perfect for aerospace and high-speed cutting tools. | High melting point (around 2,870°C) but less suitable for extreme heat compared to TaC. |

| Chemical Resistance | Shows excellent resistance to chemicals, making it ideal for corrosive environments. | Good chemical resistance, slightly less effective than TaC in highly corrosive settings. |

| Electrical Conductivity | Good conductivity with superior thermal properties, beneficial in electronic applications requiring heat management. | Good electrical conductivity, less thermal resistance compared to TaC. |

| Primary Uses | Used in high-temperature and chemically harsh environments like aerospace parts and furnace components. | Common in tooling for cutting, drilling, mining, and construction, where durability is key. |

| Cost | Generally more expensive due to specialized applications and manufacturing processes. | More cost-effective and widely available, making it a popular choice for a broad range of industrial applications. |

| Handling and Safety | Requires careful handling with dust control and protective measures to avoid inhalation or skin contact. | Similar safety protocols are needed for handling WC powder, including proper ventilation and personal protective equipment. |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Quality Control: Tantalum Carbide Powder Testing

At our company, we take the quality of our Tantalum Carbide Powder seriously. It’s not just about meeting industry standards – it’s about exceeding them. Our quality control process is thorough and meticulous, ensuring every batch of powder is up to the task, no matter the challenge. Here’s an overview of the quality testing process:[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Chemical Composition Analysis:

We start with a detailed analysis of the chemical composition. It’s not just about getting the tantalum and carbon mix right. It’s about fine-tuning the balance to achieve that perfect blend, tailored for peak performance.

Particle Size Distribution:

We know that the particle size can make or break a product’s efficiency. That’s why we rigorously test for particle size distribution. Whether it’s for fine precision work or heavy-duty applications, we ensure our powder’s particle size is spot on.

Purity Testing:

Purity affects the powder’s quality, impurities can change its properties. We use advanced methods like ICP-MS and XRF. We confirms the high purity needed for sensitive applications.

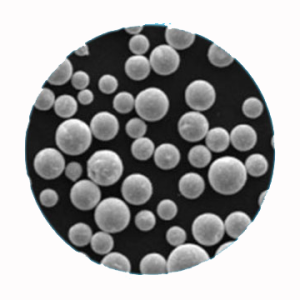

Enhanced Microstructural Inspection:

We regularly use Scanning Electron Microscopy (SEM). This lets us closely look at particle shapes and spaces. We do this to make sure everything meets our high-quality standards

Physical Property Assessment:

Properties like hardness and melting point are tested. These are important for the powder’s performance. They ensure the powder can handle the conditions it will face in use.

In our company, quality control isn’t just a procedure – it’s a promise. A promise that our Tantalum Carbide Powder isn’t just good, it’s the best it can be for our customers, every single time.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Scanning Electron Microscopy (SEM)

[/vc_column_text][/vc_column][/vc_row]