[vc_row][vc_column][vc_column_text css=””]

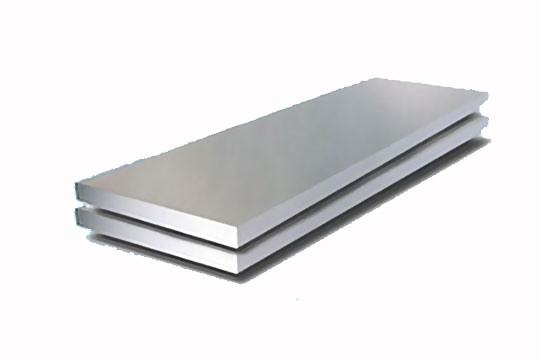

High-Quality Tantalum Plates: Your Reliable Source for Advanced Materials

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”Our Tantalum Plate Products” txt_align=”center” css=””]

Various Grades and Alloys of Tantalum Plates

Customization: Sizes, Thickness, and Finish Options

[/vc_cta][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Tantalum Plate Specifications

| Condition: | Annealed |

|---|---|

| Size | Thickness: 0.07-10 mm |

| Width: 30-1000 mm | |

| Length: 30-3000 mm | |

| Material | UNS R05200, UNS R05400 |

| Standard | ASTM B708-98 |

| Purity | ≥99.95% or 99.99% |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Sizes/Tolerance(mm max)

| Thickness | Tolerance | Width | Tolerance | Length | Tolerance | |

|---|---|---|---|---|---|---|

| GradeⅠ | gradeⅡ | |||||

| >0.15-0.2 | ±0.015 | ±0.02 | 50-300 | ±2.0 | 100-1000 | ±2.0 |

| >0.2-0.3 | ±0.020 | ±0.03 | 50-300 | ±1.0 | 100-1000 | ±2.0 |

| >0.3-0.5 | ±0.030 | ±0.04 | 50-500 | ±1.0 | 100-1500 | ±2.0 |

| >0.5-0.8 | ±0.040 | ±0.06 | 50-500 | ±1.0 | 50-2000 | ±2.0 |

| >0.8-1.0 | ±0.060 | ±0.08 | 50-500 | ±1.0 | 50-2000 | ±2.0 |

| >1.0-1.5 | ±0.080 | ±0.10 | 50-500 | ±2.0 | 50-2000 | ±2.0 |

| >1.5-2.0 | ±0.120 | ±0.14 | 50-500 | ±2.0 | 50-2000 | ±2.0 |

| >2.0-3.0 | ±0.160 | ±0.18 | 50-500 | ±2.0 | 50-2000 | ±2.0 |

| >3.0-4.0 | ±0.180 | ±0.20 | 50-500 | ±1.0 | 50-1500 | ±1.0 |

| >4.0-6.0 | ±0.200 | ±0.24 | 50-350 | ±1.0 | 50-1500 | ±1.0 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Chemical Composition of Tantalum Plate

| Element | R05200 (%,Max) | R05400 (%,Max) |

|---|---|---|

| C | 0.01 | 0.01 |

| O | 0.015 | 0.03 |

| N | 0.01 | 0.01 |

| H | 0.0015 | 0.0015 |

| Fe | 0.01 | 0.01 |

| Mo | 0.02 | 0.02 |

| Nb | 0.1 | 0.1 |

| Ni | 0.01 | 0.01 |

| Si | 0.005 | 0.005 |

| Ti | 0.01 | 0.01 |

| W | 0.05 | 0.05 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Why Choose Our Tantalum Plates

Competitive Edge of Our Products

Our tantalum plates stand out in the market. Each plate is crafted to perfection and we use advanced manufacturing techniques.

Innovative Solutions:

We’re always innovating. Our R&D team works on new alloys and treatments. This keeps our tantalum plates at the forefront of technology.

Longevity and Reliability

Our tantalum plates are built to last. They withstand harsh conditions without degradation, this makes them a reliable choice for critical applications.

Customer Satisfaction and Trust

Our customers trust us for their needs. We’ve built this trust over years of delivering excellence. We listen to feedback, continuously improve our products and services.

Global Reach and Accessibility

We serve clients globally. Our efficient freight service ensures timely delivery. No matter where you are, you can get our high-quality tantalum plates quickly.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Applications and Industry Uses

” font_container=”tag:h2|text_align:center” css=””][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_column_text css=””]

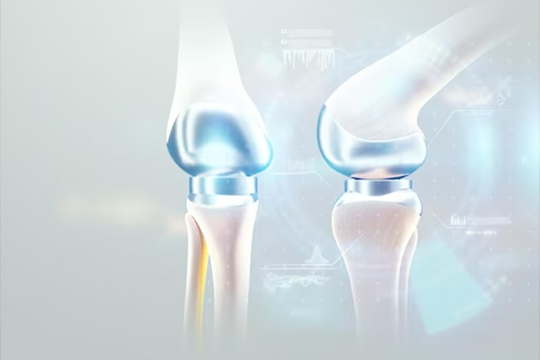

Medical Materials:

Tantalum plates are used in medical instruments due to their biocompatibility. They are ideal for implants like artificial joints, artificial ears, and pacemakers.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

Aerospace Applications

In aerospace and defense, tantalum’s resilience is vital. Our plates are used in aircraft engines and space vehicles.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

Laboratory Use

Tantalum sheets are commonly used in laboratories as sample supports, spacers, and conductive materials.[/vc_column_text][/vc_column][vc_column width=”1/4″][vc_column_text css=””]

Chemical Equipment

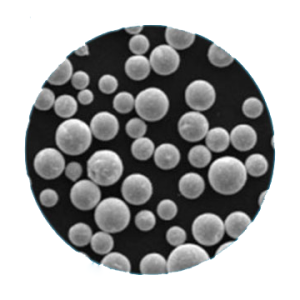

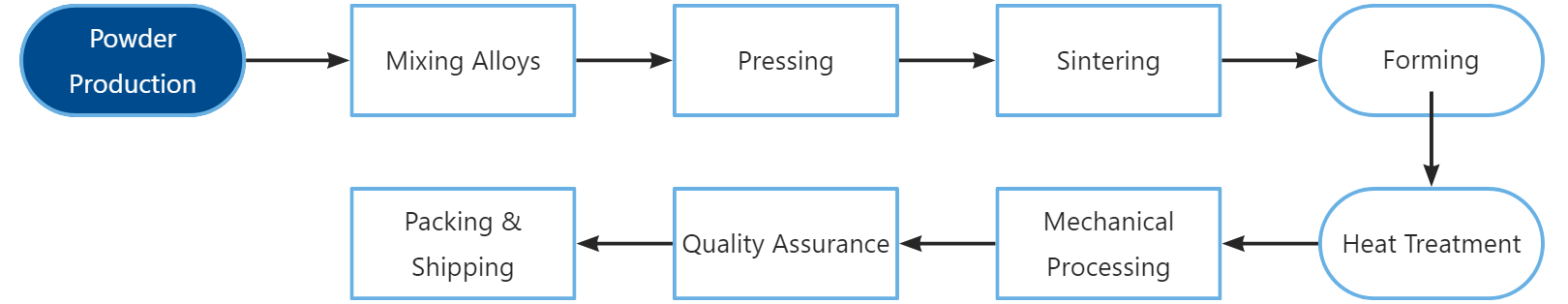

Our tantalum plates excel in chemical processing, they resist corrosion from acids and alkalis. This makes them perfect for reactors and storage tanks.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Manufacturing Processes of Tantalum Sheet Based On Powder Metallurgy

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Advanced Powder Production

Mixing Alloys

Precision Pressing and Shaping

Cutting-Edge Sintering Process

Forming for Enhanced Durability

Specialized Heat Treatment

Precision Mechanical Processing

Final Product Inspection

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Your Comprehensive Guide to Purchasing Tantalum Plates

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

What is Tantalum Plate? A Brief Overview

Tantalum plates are high-performance materials made from tantalum metal. This rare element is known for its robustness and versatility. The plates are used in various demanding applications due to their unique properties. They offer a combination of strength, ductility, and resistance to corrosion and high temperatures.

Unique Properties of Tantalum Plate

Corrosion Resistance:

Tantalum plates can withstand exposure to a wide range of chemicals, without corroding. This makes them ideal for chemical processing environments.

High Melting Point:

They have one of the highest melting points among metals, which ensures performance under extreme heat.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]Excellent Conductivity:

Their conductivity makes them suitable for electronic applications, especially where heat resistance is crucial.

Strength-to-Weight Ratio and Durability:

Tantalum’s density is about 16.4 g/cm³, contributing to its strength and durability. Tantalum plates have a high strength-to-weight ratio, offering robustness without excess weight. It’s durable, even in demanding applications. This strength ensures long-term performance and reliability.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”What is the Difference Between Tantalum Plate and Tantalum Sheet?” css=””]

Definition and Thickness:

Tantalum Plate: Tantalum plates are thicker and more robust. The thickness of a plate is usually greater than 0.187 inches (4.75 mm).

Tantalum Sheet: Tantalum sheets are thinner, offering more flexibility. Sheets are usually less than 0.187 inches thick (4.75mm).

Application Differences:

Usage in Heavy-Duty Applications: Tantalum plates are ideal for heavy-duty industrial uses. This includes aerospace components, chemical processing equipment, and nuclear reactors.

Their thickness provides added strength and resistance to extreme conditions.

Precision Applications:

Tantalum sheets are suitable for delicate, precision applications. This includes electronic components, medical devices, and fine chemical filtration systems. Their thinner and more pliable nature allows for precise customization.

Mechanical Properties Strength and Resistance:

Plates generally offer higher strength and resistance to wear and tear compared to sheets. This is due to their greater thickness and structural integrity.

Flexibility and Malleability: Sheets, being thinner, provide more flexibility. They can be molded and shaped more easily than plates.

[/vc_cta][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Grades of Tantalum Plate

Our selection of tantalum plates encompasses a variety of grades. Each is specifically suited to meet diverse application needs. Tantalum’s unique properties make it invaluable across many industries.

From aerospace to medical technology, its versatility is unmatched.

| Grade | Description | Primary Applications |

|---|---|---|

| R05200 | Unalloyed tantalum, pure, used primarily in chemical processing. | Chemical Processing Equipment, Semiconductor, Medical Devices, Laboratory Equipment |

| R05400 | Unalloyed tantalum, similar to R05200 but with different manufacturing. | Chemical Processing Equipment, Semiconductor, Medical Devices, Laboratory Equipment |

| R05252(Ta-2.5W) | Tantalum alloyed with 2.5% tungsten, known for durability. | Industrial Processing, Energy Sector, Automotive Industry, Electrochemical Applications |

| R05255(Ta-10W) | Tantalum alloyed with 10% tungsten, enhanced strength. | Aerospace Components, Military Applications, Nuclear Reactors, High-temperature Industrial Processes |

| R05240(Ta-40Nb) | Tantalum alloyed with 40% niobium, highly corrosion-resistant. | Medical Devices, Electronics, Superconducting Technology, Space Exploration |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Considerations Before Purchasing Tantalum Plate/Sheet

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Performance Under Stress:

Chemical Exposure:

Environmental Conditions:

Operating Temperature Range:

Thermal Expansion:

Matching Properties to Needs:

Precise Measurements:

Purity Impact:

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row]

[/vc_column_text][/vc_column][/vc_row]