[vc_row][vc_column][vc_column_text css=””]

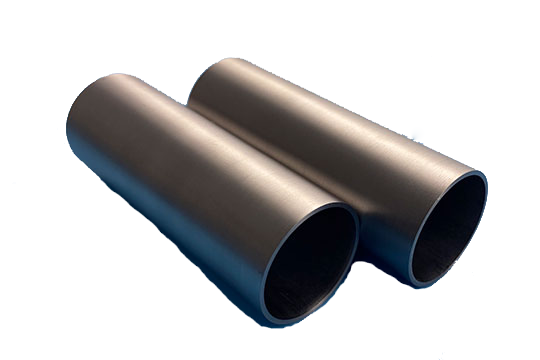

Tantalum Tube & Pipe: Your Reliable Solution for Industrial Applications

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Product Specifications: ARS Metal’s Tantalum Tubes & Pipes

Precision Engineering and Design

ARS Metal’s Tamtalum tubes and pipes are engineered with precision. We use advanced design techniques. This ensures accuracy in dimensions and shape.

Standard and Grades

Standard: ASTM B521; Grade: R05200, R05400, R05252 (Ta-2.5W), R05255 (Ta-10W)

Customization Capabilities

We offer customized sizes, shapes, thicknesses, and a range of finishes to ensure our products precisely fit your project needs.

Surface Condition of Tantalum Tube:

Outside surface – Polished, Roughness Ra<3.2

Inside surface – Depends on the diameter

Our Tantalum Tube Standard Specifications

We provide high-quality tantalum tubes and pipes, available in both seamless and welded styles. A variety of standard sizes are offered, and for any specific size requirements not listed, we encourage you to contact us for personalized assistance.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

| Outer Diameter, Inch (mm) | Diameter Tolerance, Inch (mm), +/- | Wall Thickness Tolerance, %, +/- |

|---|---|---|

| <1 (25.4) | 0.004 (0.102) | 10 |

| 1~1.5 (25.4~38.1) | 0.005 (0.127) | 10 |

| 1.5~2 (38.1~50.8) | 0.006 (0.152) | 10 |

| 2~2.5 (50.8~63.5) | 0.007 (0.178) | 10 |

| 2.5~3.5 (63.5~88.9) | 0.010 (0.254) | 1 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Physical Property of Tantalum Tube

| Grade | Tensile Strength δbpsi (MPa), ≥ | Yield Strength δ0.2, psi (MPa),≥ | Elongation in 1″/2″ Gage Length, %, ≥ |

|---|---|---|---|

| R05200/R05400 | 30000 (207) | 20000 (138) | 25 |

| R05252 | 40000 (276) | 28000 (193) | 20 |

| R05255 | 70000 (481) | 60000 (414) | 15 |

| R05240 | 40000 (276) | 28000 (193) | 20 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”Why Choose Our Tantalum Tubes?” css=””]

Industry-Leading Expertise and Support

Strictest Tolerance

Bend Control:

Exceptional Purity Levels:

Certifications and Quality Standards

[/vc_cta][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Tantalum Tube Applications

Tantalum and tantalum alloy tubes, including Ta-2.5W, Ta-10W, and Ta-40Nb, are highly valued for their unique properties. They have a high melting point and resist corrosion well. They’re also easy to shape and use in cooler temperatures. These features make them perfect for many industries.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

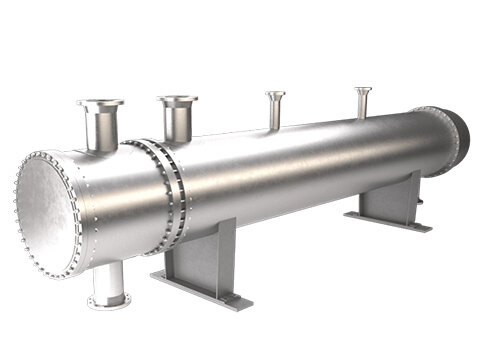

Chemical Industry

Building reaction containers and heat exchangers. These components are crucial for various chemical processes.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Aerospace and Defense

Their strength and durability are crucial in extreme space conditions. Making them ideal for critical components like airplane engines.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Renewable Energy Systems

In renewable energy, tantalum tubes are great for outdoors. They’re used in solar panels and wind turbines because they’re strong and last long.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Manufacturing Processes for Tantalum Tube” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”Why Choose Us?” css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”Why Choose Us?” css=””]

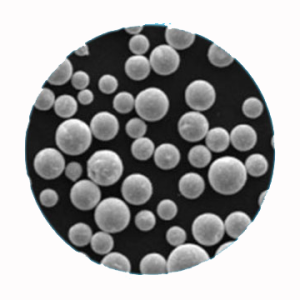

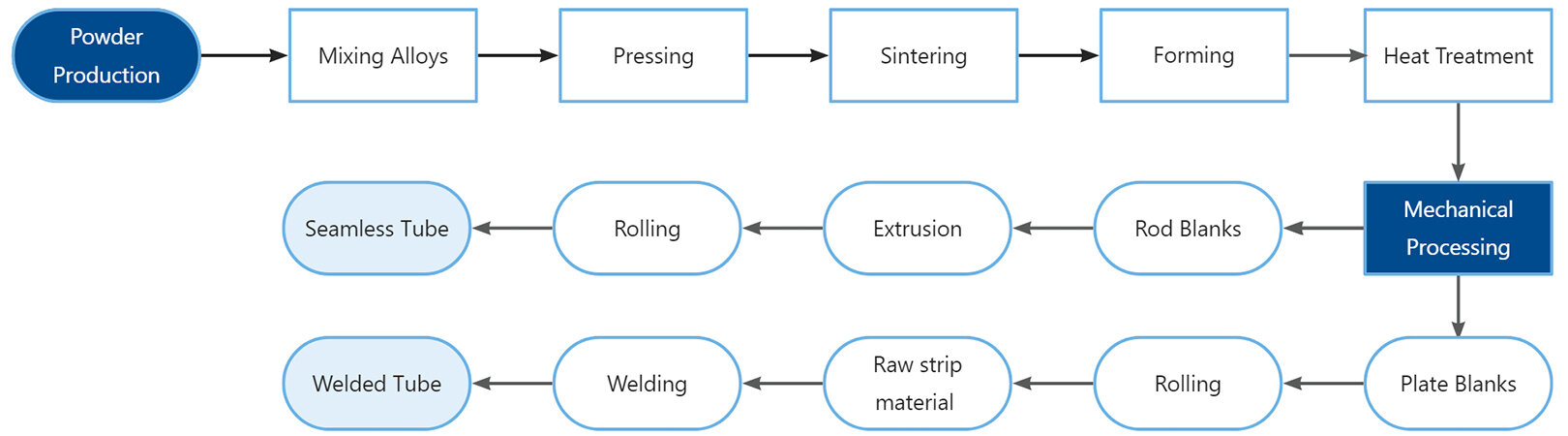

Advanced Powder Production

ARS Metal uses advanced chemical reduction to create ultra-pure, uniform metal powders. This process is key for high-quality metal products.

Mixing Alloys

Our alloy mixing process is characterized by meticulous precision. This creates alloys with unmatched performance and reliability.

Precision Pressing and Shaping

Using state-of-the-art pressing techniques, we mold our metal powders into desired shapes. Our technology excels in producing complex geometries with high precision.

Cutting-Edge Sintering Process

Our sintering process employs advanced technology. It bonds powder grains effectively, creating dense and robust sinter blocks. This step is crucial for the durability of our products.

Forming for Enhanced Durability

We use unique forming methods to increase material density and strength. Our process ensures our tantalum can withstand rigorous applications.

Specialized Heat Treatment

Our heat treatment process is tailored to each product. It fine-tunes the mechanical properties of the metal, ensuring ease of subsequent processing and optimal performance.

Precision Mechanical Processing

ARS Metal provides specialized mechanical processing to shape tantalum into various forms. We create rod blanks for seamless tubes and plate blanks for welded tubes.

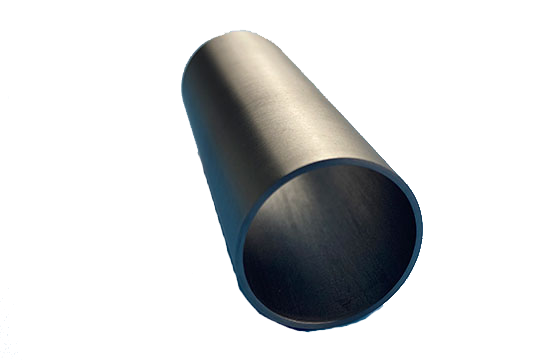

Seamless Tube

To produce our seamless tubes, we follow a precise process that includes Extrusion and Rolling, culminating in the final seamless tube. This streamlined approach ensures high-quality and consistency in our tube manufacturing.

Welded Tube

Our welded tube production involves a methodical process beginning with Rolling, followed by shaping Raw strip material. This is then welded to form the Welded tube, ensuring a high standard of quality and structural integrity in our final product.[/vc_cta][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Tantalum Tube: A Comprehensive Guide for Buyer

What is Tantalum Tube? A Brief Overview

Tantalum tubes are cylindrical materials made from the element tantalum. Known for their high melting point and resistance to corrosion, these tubes are used in various industries, including chemical industry and aerospace technology. They are prized for their durability and ability to withstand extreme environments.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Unique Properties of Tantalum Tube

Exceptional Corrosion Resistance:

Tantalum tubes resist corrosion from acids and bases, making them suitable for chemical processing and handling corrosive substances.

High Melting Point:

With a melting point of around 2996°C, tantalum tubes maintain structural integrity in high-temperature applications.

Good Ductility and Malleability:

Tantalum can be formed into different shapes and sizes, allowing for versatile use in various industries.

High Density and Strength:

They offer strength and durability without being overly heavy, crucial for aerospace and military uses.

Low Vapor Pressure:

This property enables tantalum tubes to perform well in vacuum environments, ideal for space applications.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Grades of Tantalum Tube

Tantalum tubes come in various grades, each tailored for specific industry applications:

| Grade | Description | Main Application |

|---|---|---|

| Grade R05200 | Unalloyed Tantalum, Electron Beam or Vacuum Arc Melted | Used in the semiconductor industry for manufacturing sputtering targets and furnace parts. Its high purity is crucial for these applications. |

| Grade R05400 | Unalloyed Tantalum, Powder Metallurgy | Ideal for pharmaceutical equipment due to its inertness and corrosion resistance. Used in reaction vessels and heat exchangers. |

| Grade R05255 | Tantalum Alloy, 90% Tantalum, 10% Tungsten | Utilized in aerospace for its high strength at elevated temperatures. Common in jet engine components. |

| Grade R05252 | Tantalum Alloy, 97.5% Tantalum, 2.5% Tungsten | Preferred in chemical processing for pipelines and valves, offering enhanced strength and corrosion resistance. |

| Grade R05240 | Tantalum Alloy, 60% Tantalum, 40% Niobium | Frequently used in superconducting applications. Its unique composition makes it suitable for electronic components and cryogenic environments. |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Quality Control: Tantalum Tube Testing

Quality control is a critical part of the manufacturing process for tantalum tubes. It ensures that the tubes meet the required standards and are suitable for their intended use. Here’s an overview of the testing procedures commonly employed:

Visual Inspection:

Surface Check: The first step is a thorough visual inspection. This involves checking for surface defects like scratches, dents, or irregularities. Dimensional Accuracy: The dimensions of the tubes, including diameter, thickness, and length, are verified against specified tolerances.

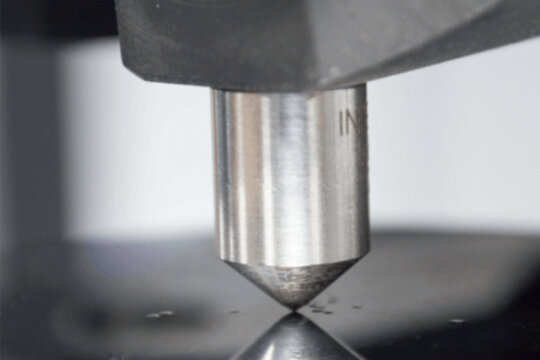

Mechanical Testing:

Tensile Test: This test measures the tube’s strength by pulling it until it breaks. The tensile strength, yield strength, and elongation are assessed. Hardness Test: A hardness test (like Rockwell or Vickers) is performed to determine the material’s resistance to indentation and wear.

Chemical Analysis:

Composition Check: Ensuring the correct chemical composition of the tantalum alloy is crucial. This is typically done using methods like X-ray fluorescence (XRF) or optical emission spectrometry (OES).

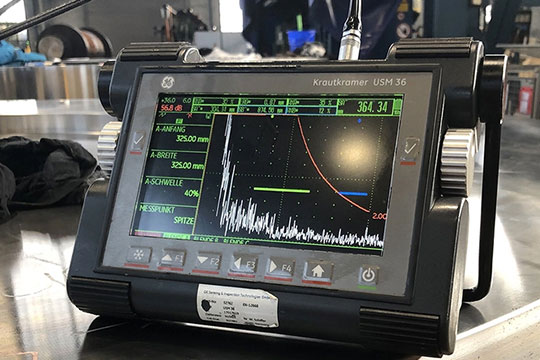

Non-Destructive Testing (NDT):

Ultrasonic Testing: Ultrasonic waves are used to detect internal flaws or inhomogeneities. Radiographic Testing: X-rays or gamma rays are used to inspect the internal structure of the tubes, identifying any internal defects.

Corrosion Resistance Testing:

Immersion Test: Tubes are immersed in aggressive chemical solutions to assess their corrosion resistance over time. Intergranular Corrosion Test: This test is specific to detect susceptibility to intergranular corrosion in the tantalum tubes.

Pressure Testing:

Hydrostatic Test: Tubes are filled with water and pressurized to check for leaks and to ensure they can withstand the expected operating pressures. Pneumatic Test: Similar to the hydrostatic test but uses air or another gas. This test is typically used when water could damage the tube.

Certification and Documentation:

After passing all tests, each batch of tubes is certified. A report is provided, detailing the tests conducted and the results.

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row]