[vc_row][vc_column][vc_column_text css=””]

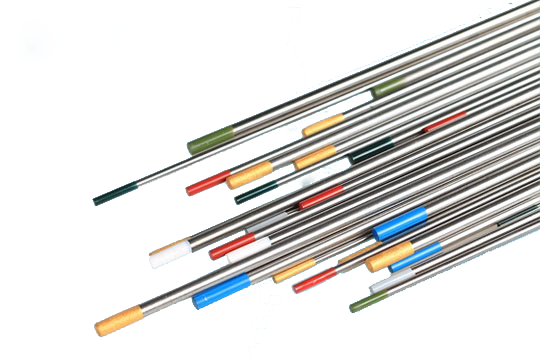

Tungsten Electrode

Tungsten electrode has a high melting point, high-density, corrosion resistance, strong electronic emission ability, conduct electricity. By adding some rare earth oxides (CeO, LaO, ThO), tungsten electrodes can be improved in the area of recrystallization temperature increasing and the ability of electron emission. For that reason, its welding performance may be better than before. During the past years, thoriated tungsten electrodes were wildly used in inert gas shield arc welding, plasma arc welding, and cutting. However, these are radioactive and unhealthy, compared to other tungsten electrodes, thoriated tungsten electrodes are replaced by created tungsten, lanthanide tungsten, multi-compound rare-earth tungsten electrode. Besides argon arc welding, tungsten electrodes are eagerly used in xenon lamp and painting fields.

Tungsten Electrode Specifications

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

DiameterDiameter ToleranceLengthLength Tolerance

| mm | inch | mm | mm | mm | |||

| 1.00 | 0.04 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 1.60 | 1/16 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 2.00 | 5/64 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 2.40 | 3/32 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 3.20 | 1/8 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 4.00 | 5/32 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 4.80 | 3/16 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 6.40 | 1/4 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 8.00 | 5/16 | ±0.05 | 50, 75, 150, 175, 178 | ±0.10 | |||

| 10.00 | 25/64 | ±0.05 | 50, 75, 150, 175, 178 | ±0.1 | |||

Lanthanated-Tungsten Electrode

Lanthanated tungsten electrode is similar to thoriated tungsten electrode with the characters of on-radioactive, excellent electric conductivity, welding performance, high carrying capability, and a minimum ratio of burnt area. It can be substituted for a thoriated tungsten electrode, which is mainly used for DC welding.

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

TypeOxide AdditionDopantImpuritiesWElectric Work FunctionColor

| WLa10 | La2O3 | 0.8-1.2% | <0.05% | Bal. | 2.8 eV-3.2 eV | Black | ||

| WLa15 | La2O3 | 1.3-1.7% | <0.05% | Bal. | 2.8 eV-3.2 eV | Golden | ||

| WLa20 | La2O3 | 1.8-2.2% | <0.05% | Bal. | 2.8 eV-3.2 eV | Sky blue | ||

Multi-compond Rare-earth Tungsten Electrode

The compound rare earth Tungsten electrode is doped with various oxides, with excellent welding performance.

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

TypeOxide AdditionDopantImpuritiesWElectric Work FunctionColor

| WXY30 | Multi-compond rare-earth | 1.0-4.0% | <0.05% | Bal. | 2.45 eV-3.10 eV | Light blue | ||

| Application | Main substitute of radioactive thoriated Tungsten electrode, and other Tungsten electrodes. | |||||||

Ceriated-Tungsten Electrode

Ceriated Tungsten electrode, with easier arc ignition, and low arc maintaining current under low current circumstances, is substituted for thoriated Tungsten electrode, especially for DC welding.

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

TypeOxide AdditionDopantImpuritiesWElectric Work FunctionColor

| WCe20 | CeO2 | 1.8-2.2% | <0.05% | Bal. | 2.7 eV-2.8 eV | Gray | ||

| Application | Applied for the welding of pipelines, and small components, and discontinuous welding. | |||||||

Thoriated-Tungsten Electrode

It is radioactive. If it is compared with pure Tungsten electrodes and others, its welding performance is more excellent, with the advantages of easy operating, stable electric arc, and long-life.

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

TypeOxide AdditionDopantImpuritiesWElectric Work FunctionColor

| WTh10 | ThO2 | 0.9-1.2% | <0.05% | Bal. | 2.0 eV-3.9 eV | Yellow | ||

| WTh20 | ThO2 | 1.8-2.2% | <0.05% | Bal. | 2.0 eV-3.9 eV | Red | ||

| WTh30 | ThO2 | 2.8-3.2% | <0.05% | Bal. | 2.0 eV-3.9 eV | Purple | ||

| WTh40 | ThO2 | 3.8-4.2% | <0.05% | Bal. | 2.0 eV-3.9 eV | Orange | ||

| Application | Mainly applied for carbon steel, stainless steel, nickel alloy. | |||||||

Zirconium-Tungsten Electrode

Zirconiated Tungsten, with the advantages of AC welding, especially under high load current, can not be replaced by any other Tungsten electrodes.This kind of Tungsten electrode retains a balled end when welding, with corrosion resistance.

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

TypeOxide AdditionDopantImpuritiesWElectric Work FunctionColor

| WZr3 | ZrO2 | 0.2-0.4% | <0.05% | Bal. | 2.5 eV-3.0 eV | Brown | ||

| WZr8 | ZrO2 | 0.7-0.9% | <0.05% | Bal. | 2.5 eV-3.0 eV | White | ||

| Application | Suitable for AC welding of aluminum, magnesium, and their alloys. | |||||||

Pure Tungsten Electrode

Non-addition, requiring a high voltage for arc derivation, low current capacity, and easily burnt.

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

TypeOxide AdditionDopantImpuritiesWElectric Work FunctionColor

| H3N5 | — | — | <0.05% | Bal. | 4.5 eV | Green | ||

| Application | Suitable for AC welding of aluminum, magnesium, and their alloys. | |||||||

Yttrium-Tungsten Electrode

A long, thin arc beam with high compression, deeper burning groove under medium and high current circumstances.

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

TypeOxide AdditionDopantImpuritiesWElectric Work FunctionColor

| WY20 | Y2O3 | 1.8-2.2% | <0.05% | Bal. | 2.0 eV-3.9 Ev | Blue | ||

| Application | Mainly apllied for military industry and aerospace industry. | |||||||

Black Tungsten Electrode

The Tungsten electrode rod is manufactured by forging, drawing, coarse grinding, and fine grinding process. We can supply any specifications of the Tungsten electrode rod.

td {white-space:nowrap;border:1px solid #dee0e3;font-size:10pt;font-style:normal;font-weight:normal;vertical-align:middle;word-break:normal;word-wrap:normal;}

TypeOxide AdditionDopantImpuritiesWElectric Work Function

| WCe20 | CeO2 | 1.8-2.2% | <0.05% | Bal. | 2.7 eV-2.8 eV | ||

| WLa15 | La2O3 | 1.3-1.7% | <0.05% | Bal. | 2.8 eV-3.0 eV | ||

| WTh20 | ThO2 | 1.8-2.2% | <0.05% | Bal. | 2.0 eV-3.9 eV | ||

| Application | Applied for argon arc welding under the low current circumstance. Its usage condition is the same as kinds of Tungsten electrode. | ||||||

[/vc_column_text][/vc_column][/vc_row]