[vc_row][vc_column][vc_column_text css=””]

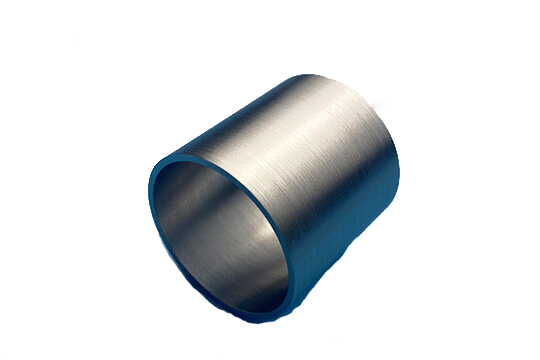

Tungsten Tubes & Pipes

A tungsten tube, also called a tungsten pipe, is a type of cylinder-shaped tube made from the chemical element tungsten. Tungsten tubes are really strong and durable. They are used in many different industries because of their exceptional strength and durability.

Metals offers custom-made tungsten tubes and tungsten pipes for high-temperature applications. Our products are designed with precision and tailored specifications to meet your specific needs.

Purity: W ≥ 99.95%

Density: 17.8 – 18.3 g/cc

Hardness: > 450 HV

Supply state: Sinterring or processing

Size: 3 – 500 mm OD x 0.5 – 30 mm wall thickness x L

W-La Tubes

Tungsten Lanthanum (WLa) tubes represent a specialized and high-performance class of materials with unique properties that make them valuable in various technological applications. These tubes are composed of tungsten (W) and lanthanum (La), a rare-earth element. The combination of these materials results in enhanced characteristics that set WLa tubes apart in terms of performance and reliability.

When you prefer to tungsten tubes with long length and thin thickness, W-La (La2O3 0.8 – 1.2 wt%) tubes would be a better choice than pure tungsten tubes.

WLa tubes represent an advanced material solution, combining the robustness of tungsten with the advantageous properties imparted by lanthanum. Their versatility makes them a preferred choice in industries demanding high-performance materials capable of withstanding extreme conditions. Whether in aerospace, medical, or research applications, WLa tubes continue to contribute to technological advancements with their unique set of features.

Send Inquiry

Chemical Composition of Tungsten Sheets

| W (≥%) | Chemical Content (≤ %) | |||||||||||||

| 99.95 | K | Fe | Al | Mo | Si | As | Ca | Cr | Mg | Mn | Na | Ni | Bi | Cd |

| 0.0015 | 0.003 | 0.003 | 0.003 | 0.0015 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.0005 | 0.0005 | |

| Cu | Pb | Sb | Co | Ti | Sn | |||||||||

| 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |||||||||

The Process of Manufacturing Tungsten Tubes

Sintering

Sintering is a key method in the manufacturing of tungsten tubes. It involves compacting tungsten powder into a green compact, followed by a high-temperature treatment (typically in a vacuum or hydrogen atmosphere) just below the melting point of tungsten. This process allows the tungsten particles to bond, resulting in a solid, dense structure.

In tube production, sintering is employed after pressing or forming processes. The compacted tungsten powder is shaped into the initial tube form, and sintering imparts strength and cohesion to the structure.

Machining

Machining involves the removal of material through various processes such as cutting, drilling, and turning to achieve specific dimensions, shapes, and surface finishes. Precision machining is crucial to meet tight tolerances and quality requirements.

After sintering, tungsten tubes often undergo precision machining to achieve final dimensions and features. This may include cutting the tube to the desired length, drilling holes, and ensuring the tube meets the required specifications.

Welding

Welding is a joining process that involves the fusion of two or more pieces of material to create a unified structure. Tungsten inert gas (TIG) welding is commonly used for tungsten materials due to its high melting point.

Welding may be used to join tungsten tubes or to attach additional components to the tubes.

Powder Metallurgy and Forming: The primary methods for tungsten tube manufacturing involve powder metallurgy, pressing, and forming processes, with sintering as a crucial step within these methods. These processes help shape tungsten into the desired tube structure.

Customization: Machining and welding are often used for customization and secondary processes after the initial forming and sintering steps.

Quality Control: Rigorous quality control measures are implemented at each stage, ensuring the final tungsten tubes meet specific standards and requirements.

In summary, sintering is a fundamental process in tungsten tube manufacturing, while machining and welding are complementary processes used for shaping and customization. The selection of methods depends on the specific requirements of the application and the desired properties of the tungsten tubes.

Send Inquiry

Custom Solutions: Tailoring Tungsten Tubes to Industry Needs

Precision Machining for Custom Dimensions:

Exact Specifications:

Precision machining techniques enable the customization of tungsten tubes to exact specifications, ensuring they meet the dimensional requirements of specific applications.

Tight Tolerances:

Custom solutions often demand tight tolerances. Precision machining allows for the creation of tungsten tubes with exceptionally small tolerances, crucial in applications where precision is paramount.

Alloying for Enhanced Properties:

Alloy Combinations:

Tungsten can be alloyed with other elements to create tailored solutions. Alloying may enhance certain properties, such as ductility, toughness, or resistance to specific environmental conditions.

Unique Shapes and Configurations:

Bespoke Designs:

Custom solutions involve crafting tungsten tubes in unique shapes and configurations. This capability allows for the creation of tubes that precisely fit into complex assemblies or accommodate specific fluid dynamics requirements.

Complex Geometries:

Advanced machining technologies enable the production of tungsten tubes with intricate geometries, addressing the specific needs of applications in industries such as aerospace, electronics, and medical devices.

Welding and Joining Techniques:

Integration into Assemblies:

Enhanced Weldability:

Custom solutions may involve optimizing the weldability of tungsten tubes, allowing for efficient joining processes without compromising the material’s integrity.

Industry-Specific Requirements:

Aerospace & Defense:

Tailored tungsten tubes for aerospace applications may involve lightweight designs with enhanced strength, meeting the stringent demands of aircraft components.

Medical Devices:

Custom tungsten tubes for medical devices may focus on biocompatibility, precision for imaging applications, or compatibility with sterilization processes.

Electronics and Semiconductors:

Industry-specific requirements in electronics may demand tungsten tubes with precise dimensions for use in semiconductor manufacturing or as components in electronic devices.

[/vc_column_text][/vc_column][/vc_row]