[vc_row][vc_column][vc_column_text css=””]

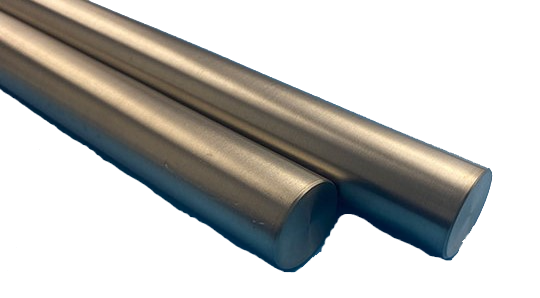

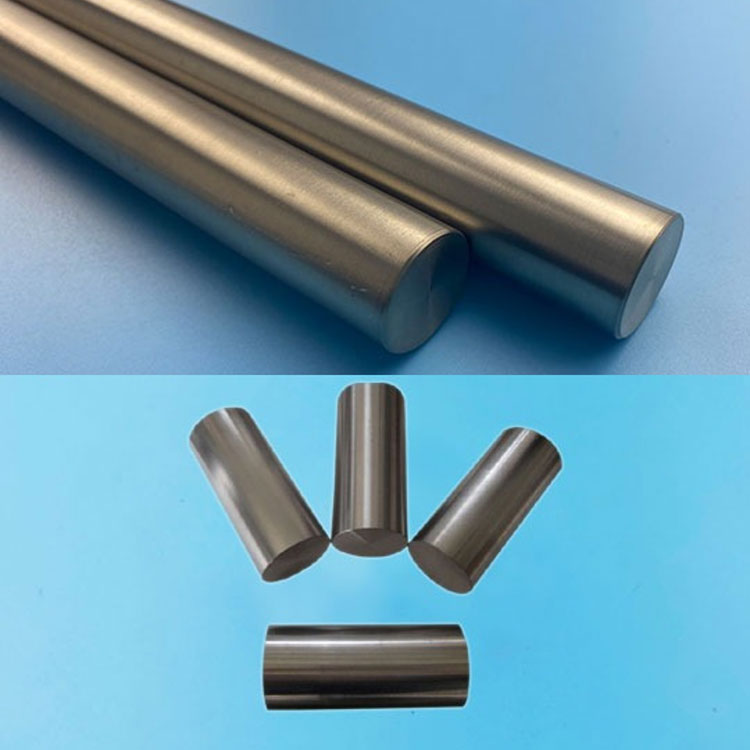

Unrivaled Zirconium Rod Excellence: Engineered for Performance

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

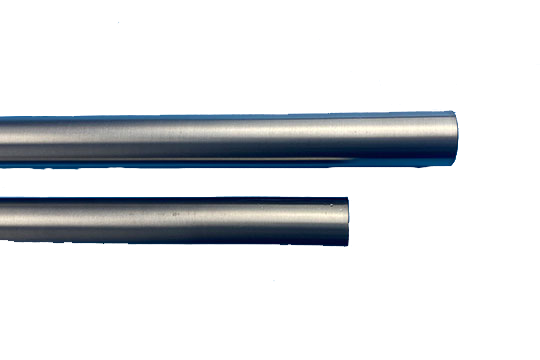

Specifications of Zirconium Rod

| Size | Dia.: 5 mm – 400 mm |

|---|---|

| Material | R60702, R60704, R60705 |

| Standard | ASTM B550, ASTM B351 |

| Surface | Black, pickling, sand-blasting, polished |

| Condition | Cold rolled(Y), hot rolled(R), annealed (M), quenching (C) |

| Shape | Square rod, round rod, hexagonal rod. |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Chemical Composition of Zirconium Rod

| Grade | Element Composition (%) < | ||||||||

| Zr+Hf | Hf | Fe+Cr | Sn | H | N | C | Nb | O | |

| R60702 | 99.2 | 4.5 | 0.2 | — | 0.005 | 0.025 | 0.05 | — | 0.16 |

| R60704 | 97.5 | 4.5 | 0.20~0.40 | 1.0~2.0 | 0.005 | 0.025 | 0.05 | — | 0.18 |

| R60705 | 95.5 | 4.5 | 0.2 | — | 0.005 | 0.025 | 0.05 | 2.0~3.0 | 0.18 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Mechanical Properties of Zirconium Rod

| Material | State | Rm (≥)/MPa | Rp0.2 (≥)/MPa | A50mm (≥)/% |

| Zirconium 702 | Annealed | 379 | 207 | 16 |

| (UNS R60702) | ||||

| Zirconium 704 | Annealed | 413 | 241 | 14 |

| (UNS R60704) | ||||

| Zirconium 705 | Annealed | 552 | 379 | 16 |

| (UNS R60705) |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Customize Your Zirconium Rod

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Why Choose ARS METAL Zirconium Rod-Our Advantages

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Unrivaled Strength

Our Zirconium Rods are engineered for superior strength, making them a reliable choice for demanding applications where durability is crucial.

Heat Resistance

Engineered to withstand high temperatures, our Zirconium Rods maintain their structural integrity even in extreme heat, ensuring stability and reliability in challenging conditions.

Enduring Durability

Crafted with precision and high-quality materials, our Zirconium Rods boast enduring durability, providing a long-lasting and reliable foundation for your projects.

Precision Machining

ARS METAL employs cutting-edge precision machining techniques to craft Zirconium Rods with exacting specifications, guaranteeing a product of outstanding quality.

Innovative Engineering

Backed by advanced engineering, our Zirconium Rods represent the forefront of metal technology, delivering innovative solutions for your projects.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”How to Make Zirconium Rod

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”How to Make Zirconium Rod

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

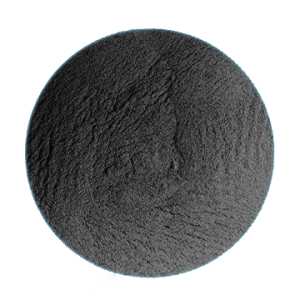

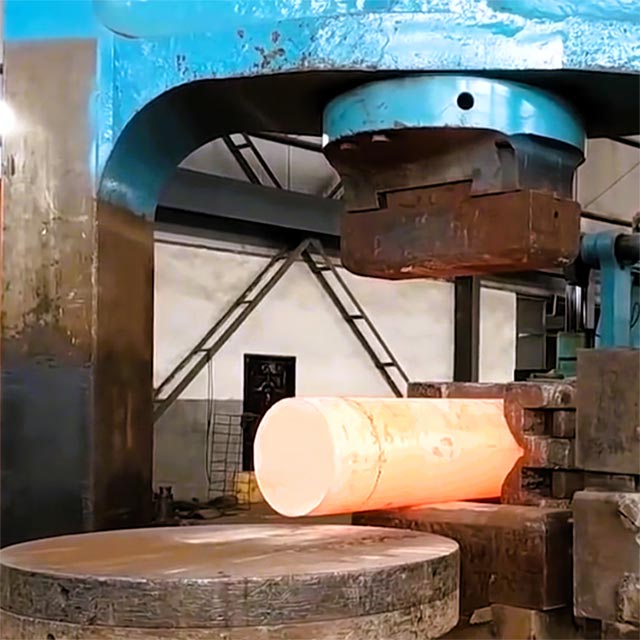

Melting and Casting:

The purified zirconium metal is melted in a controlled environment. Once molten, it is cast into ingots or billets using molds. This step establishes the initial form of the Zirconium Rods.

Hot Working:

The cast ingots may undergo hot working processes such as forging or rolling. These processes help shape the zirconium into the desired dimensions, enhancing its mechanical properties and aligning it with specific applications.

Heat Treatment:

Heat treatment is applied to the zirconium rods to optimize their mechanical properties. This controlled process involves heating and cooling to achieve the desired hardness, strength, and microstructure.

Final Finishing:

The finished Zirconium Rods undergo final finishing processes, which may include polishing or coating for specific applications.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Quality Test of Zirconium Rod

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Quality Test of Zirconium Rod

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_empty_space][vc_column_text css=””]

Surface Finish Inspection

Dimensional Accuracy

Ultrasonic Testing

Chemical Composition

Mechanical Properties

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][vc_column_text css=””]

[/vc_column_text][vc_column_text css=””]

Microstructure Examination

Hardness Testing

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Where Our Zirconium Rod Shines-Diverse Applications

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

Aerospace

Zirconium rods are utilized in aerospace applications for components that require high strength, corrosion resistance, and lightweight design.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

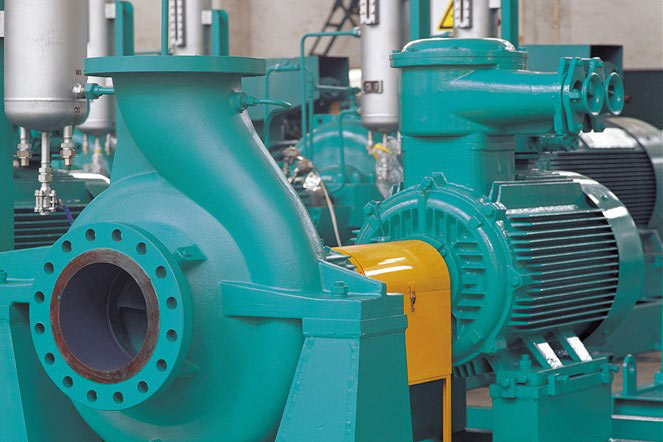

Chemical Processing

Zirconium’s excellent corrosion resistance makes it valuable in chemical processing industries, where it is used in pumps, valves, and other equipment that handle corrosive substances.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Nuclear Power

Zirconium is a key material in the nuclear industry, particularly in the production of fuel rods for nuclear reactors due to its low thermal neutron absorption and corrosion resistance.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

Medical

Zirconium is employed in medical applications, including the production of implants and devices, thanks to its biocompatibility and resistance to corrosion in physiological environments.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Oil and Gas

Zirconium rods are used in the oil and gas industry for components exposed to corrosive conditions, such as downhole tools and equipment used in offshore environments.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Electronics

Zirconium is used in electronics for its favorable electrical properties. Zirconium rods may be used in the production of certain electronic components.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”The Difference between Zirconium Rod and Zirconium Bar

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]The terms “zirconium rod” and “zirconium bar” are often used interchangeably, and their meanings can vary slightly depending on the context and industry standards. Generally, the terms refer to cylindrical forms of zirconium with similar applications and properties. However, there might be subtle differences in their dimensions or manufacturing processes based on industry norms or specific applications.

In some cases:

Zirconium Rod:

① The term “rod” typically implies a slender, elongated structure.

② Zirconium rods may have smaller diameters compared to bars and can be longer or shorter.

③ Rods may find applications in precision instruments, research, or situations where a more slender form is required.

Zirconium Bar:

① The term “bar” is often associated with a long, solid, and straight structure.

② Zirconium bars may be characterized by their larger diameters and lengths.

③ Commonly used in industrial and engineering applications where strength and durability are crucial.

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”How Zirconium Rod Outperforms Its Competitors

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”How Zirconium Rod Outperforms Its Competitors

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

Titanium Rods:

Stainless Steel Rods:

Niobium Rods:

Aluminum Rods:

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row]

[/vc_column_text][/vc_column][/vc_row]