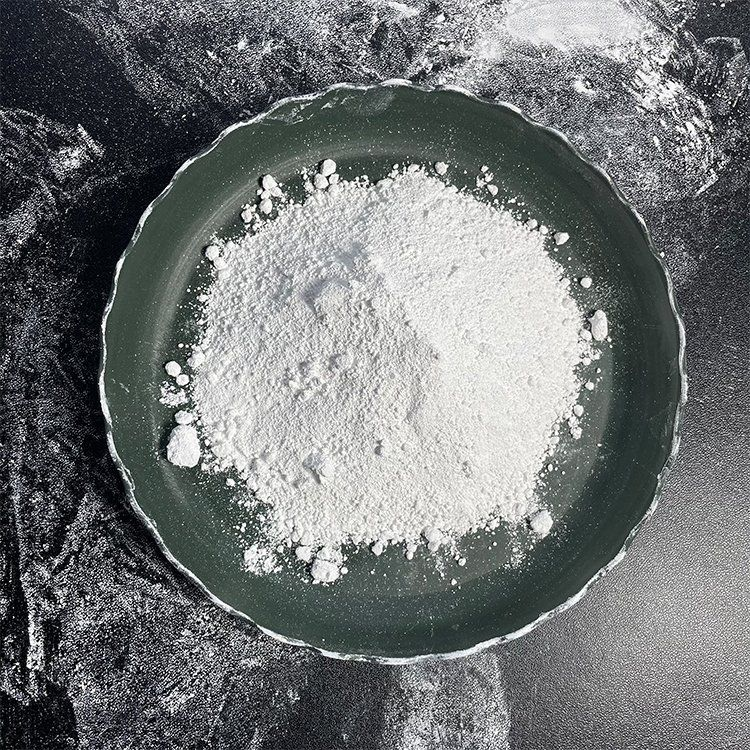

The price of titanium powder varies significantly based on factors such as purity, production methods, and market demand. Currently, titanium metal powder can range from $50 to $1,000 per kilogram, depending on these variables. Understanding the pricing trends is crucial for industries involved in manufacturing and additive processes, as it directly impacts production costs and profitability.

Various suppliers offer different qualities and pricing structures, with some estimates suggesting prices as low as $50 per kg for larger orders. For smaller volumes, prices can increase substantially, reaching over $200 per kilogram. This fluctuation underscores the importance of considering order size and specific material requirements when evaluating costs.

As the market for additive manufacturing and 3D printing continues to grow, the demand for quality titanium powder is expected to rise. Keeping informed about current pricing can help businesses make strategic decisions regarding procurement and budgeting.

Factors Influencing Titanium Powder Prices

The price of titanium powder is influenced by several critical factors. These include the costs associated with raw materials, the methods and technologies used in production, the dynamics of supply and demand, and the impact of geopolitical events and trade policies.

Raw Material Costs

The primary raw material for titanium powder is titanium sponge, which is produced through a complex extraction process from titanium ores. The price of titanium concentrates and the availability of these ores significantly influence the overall cost.

Key points:

- Fluctuations in mining costs and extraction complexities can drive prices.

- Global supply chain issues can lead to material shortages.

- Prices for titanium concentrates can vary depending on geopolitical conditions.

Production Methods and Technology

Modern production methods, such as the gas atomization process, play a vital role in determining titanium powder prices. Advanced technologies can enhance the efficiency and quality of titanium powder.

Considerations include:

- The choice of production method affects material waste and energy consumption.

- Technological advancements can reduce production costs and improve quality.

- Smaller, high-quality batches may be priced higher due to production intricacies.

Supply and Demand Dynamics

The balance of supply and demand greatly affects titanium powder pricing. A surge in demand from sectors like aerospace and medical devices can lead to price increases.

Important dynamics:

- Aerospace demand contributes significantly to market fluctuations.

- Seasonal demand variations can temporarily alter prices.

- An oversupply can stabilize or lower prices, impacting manufacturers.

Geopolitical Factors and Trade Policies

Geopolitical events and trade policies can disrupt the titanium powder market. Tariffs, embargoes, and foreign relations impact raw material availability and pricing strategies.

Influences to consider:

- Trade agreements or sanctions may affect import costs.

- Regional conflicts can disrupt supply chains, raising prices.

- Domestic production incentives can influence local pricing structures.

Current Market Trends

The titanium powder market is characterized by specific historical patterns, recent price fluctuations, and comparative analyses with other metal powders. Understanding these trends is essential for stakeholders closely monitoring pricing dynamics.

Historical Price Trends of Titanium Powder

Historically, the price of titanium powder has shown considerable variability driven by factors such as supply chain disruptions and shifts in demand from the aerospace and automotive industries.

In 2022, prices peaked, reaching over $40 per kilogram due to rising production costs and an increase in demand. However, from late 2023 to early 2024, prices experienced corrections as markets stabilized.

Annual reviews indicate fluctuations typically align with geopolitical events and raw material availability. Data from the IMARC Group indicates a price of 2475 USD/MT in the USA by December 2023, a noteworthy figure that reflects the market’s response to global economic conditions.

Recent Fluctuations in Pricing

Recently, titanium powder prices have demonstrated fluctuations driven by various market dynamics. For instance, in early 2024, prices decreased by approximately 4.46%, reflecting market adjustments and possible oversupply issues. The current pricing is around 10,000 CNY per kg, illustrating the sector’s volatility.

Market observers note that seasonal demand and production levels significantly impact these trends. The demand for titanium in industries such as medical devices and additive manufacturing remains robust, causing localized price increases despite a general downtrend.

Stakeholders can anticipate potential price hikes, particularly as global demand for high-grade titanium powder increases, especially in niche markets.

Comparison with Other Metal Powders

When comparing titanium powder prices with other metal powders, significant differences emerge. For example, aluminum powder typically averages $1.50 to $3.00 per kilogram, presenting a stark contrast to titanium prices. This discrepancy stems from titanium’s unique properties and higher production costs.

Nickel powders, often used in aerospace applications, range between $5 and $15 per kilogram, reflecting similar market pressures. The luxury of titanium’s lightweight and strength makes it preferable for specific applications despite its higher costs.

In niche sectors, titanium remains competitive against other specialty powders, as industries continue valuing performance over mere cost. This preference may sustain titanium powder’s pricing even amid economic uncertainties.

Applications and Demand for Titanium Powder

Titanium powder has multiple applications across various industries, driven by its unique properties. The demand for titanium powder continues to grow as technology advances and expands its usage.

Industries Utilizing Titanium Powder

Titanium powder is essential in several industries due to its high strength-to-weight ratio and excellent corrosion resistance. Key sectors include:

- Aerospace: It is used for manufacturing aircraft components, reducing weight while maintaining strength and durability.

- Medical: In medical devices and implants, titanium’s biocompatibility is crucial, making it preferable for surgical applications.

- Automotive: Lightweight titanium components enhance fuel efficiency and performance.

- Chemical Processing: Its resistance to corrosion allows for its use in pipes and reactor vessels.

The versatility of titanium powder makes it suitable for additive manufacturing and traditional manufacturing processes.

Impact of Technological Advancements on Demand

Technological innovations have significantly influenced the demand for titanium powder. The growth of additive manufacturing (3D printing) is one of the primary drivers. Technologies capable of producing intricate shapes and components from titanium powder have expanded its application range.

Additionally, advancements in powder metallurgy enhance the properties of titanium products, making them more desirable in high-performance contexts.

As manufacturers adopt these technologies, the need for high-quality titanium powder increases. The integration of smart manufacturing practices promises further efficiency and innovation in how titanium components are produced and utilized.

Future Projections for Titanium Powder Usage

The titanium powder market is expected to grow significantly, with projections indicating it could reach a valuation of $5 billion by 2030. Factors contributing to this growth include:

- Increasing demand in aerospace and automotive sectors.

- Expansion in medical applications, particularly in implants and prosthetics.

- Enhancement in recycling technology, which reduces costs and improves sustainability.

The rising popularity of alloyed titanium powders is also notable, as they cater to specific requirements in various applications. With projections showing a CAGR of over 14% from 2023 to 2032, the future for titanium powder looks promising across multiple industries.

Conclusion

The pricing of titanium powder is influenced by various factors, including grade, order volume, and production methods. Understanding these intricacies helps consumers and industries make informed purchasing decisions.

Summary of Key Points Discussed

The price range for titanium powder varies significantly. According to recent data, costs can range from $50 to over $1000 per kg, depending on factors like the powder grade and processing techniques. For example, highly spherical plasma atomized titanium materials are at the higher end of this spectrum, while irregular powders are much more affordable.

Additionally, recent trends indicate fluctuations in market prices, with a noted decrease in titanium prices in early 2024. Long-term price behaviors reflect historical highs and lows, thus providing insight into potential future pricing strategies.

Implications of Price Trends for Consumers and Industries

The variations in titanium powder pricing carry critical implications for both consumers and industries. For manufacturers, knowing that titanium is integral to applications ranging from aerospace to medical devices influences procurement strategies. They must consider their order quantities, as bulk purchasing can yield considerable savings.

Moreover, industries may need to adapt to these fluctuations to maintain budget constraints. Companies might explore alternative materials or adjust product designs to remain cost-effective. Understanding these trends aids manufacturers in forecasting expenses and improving overall resource management.

Final Thoughts on the Future of Titanium Powder Pricing and Market Stability

Market stability for titanium powder prices depends on several external factors, including global demand and supply chain dynamics. As industrial applications continue to evolve, these factors will likely shape the future landscape.

Additionally, technological advancements in production methods could alter current pricing dynamics. For instance, more efficient manufacturing processes may result in lower production costs, consequently influencing market prices.

In conclusion, stakeholders in the titanium market must stay informed about these trends to navigate the complexities of pricing and supply chain management effectively. Understanding the factors that influence titanium powder pricing will be essential for making strategic, informed decisions.