[vc_row][vc_column][vc_column_text]

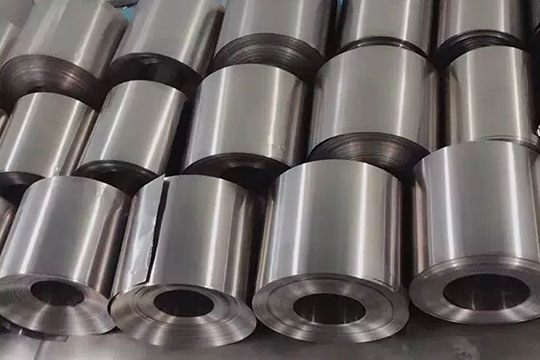

Superior-Quality Tantalum Foils with Cutting-Edge Technology

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][vc_btn title=”CONTACT US” color=”primary” css=”” link=”url:https%3A%2F%2Flydiac51.sg-host.com%2Fcontact-us%2F”][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Our Tantalum Foil Range

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Our Tantalum Foil Range

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Various Grades and Alloys of Tantalum Foils

We offer a diverse range of tantalum foils. They come in different grades and alloys. This variety ensures a perfect match for your specific need.

From pure tantalum to alloyed forms, each grade offers unique benefits. These include enhanced strength or corrosion resistance.

Tantalum Foil, Tantalum Tungsten Alloy Foil (Ta-2.5W, Ta-10W)

Grade: R05200, R05400, R05252(Ta-2.5W), R05255(Ta-10W)

Standard: ASTM B708

Purity: Ta >99.95% or >99.99%

Customization: Sizes, Thickness, and Finish Options

Your needs are unique. That’s why we offer customization. Choose from a range of sizes and thicknesses.

We also provide various finishes. Whether you need a polished surface or a specific texture, we have it.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Our Tantalum Foil Specifications

| Size | Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|---|

| Foil | 0.03-0.07 | 30-200 | >50 |

| Sheet | 0.07-0.5 | 30- 700 | 30-2000 |

| Plate | 0.5-10 | 50-1000 | 50-3000 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”Why Choose Our Tantalum Foils?” css=””]

High-Quality Surface Finish:

The surface quality of our tantalum foils is a major advantage. They have a smooth, clean finish that is essential in industries where precision and flawlessness are critical, like in advanced electronics or specialized engineering projects.

Tailored to Specific Applications:

We offer specialized doping of our tantalum foils to enhance their properties based on your application. Whether it’s improving electrical conductivity or enhancing corrosion resistance, we adjust the foil’s characteristics to meet your specific project needs.

Meeting Strict Tolerances:

Precision is vital in our production. We manufacture our tantalum foils to meet very strict tolerances. This means they have consistent thickness and dimensions, ensuring reliability and uniform performance for your applications.

Capable of Large-Scale Production:

Our manufacturing setup is designed for high production capacities. This allows us to fulfill large orders efficiently without compromising on quality.

Customizable Dimensions:

We offer tantalum foils in dimensions that are tailored to your needs. Whether you require specific lengths, widths, or thicknesses, we can produce foils that precisely match your specifications, providing a customized solution for your project.

Exceptional Purity Levels:

Our tantalum foils boast an impressive purity of up to 99.97%, ensuring top-tier quality and performance in every application.

Industry-Leading Expertise and Support

With more than 15 years of experience in manufacturing tantalum products, our team’s deep knowledge is a key strength. We help our clients pick the right foils and use them well in their projects, making sure they get the best results.

By choosing our tantalum foils, you’re selecting a product that combines superior material quality, precise engineering, and the flexibility to meet diverse industrial demands.[/vc_cta][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Foil Applications

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]Tantalum foil is a highly versatile material known for its exceptional qualities. It’s highly resistant to corrosion, can withstand extreme temperatures, and conducts electricity well. These properties make it invaluable across various industries. From electronics to aerospace, tantalum foil is a key component due to its durability and efficiency.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

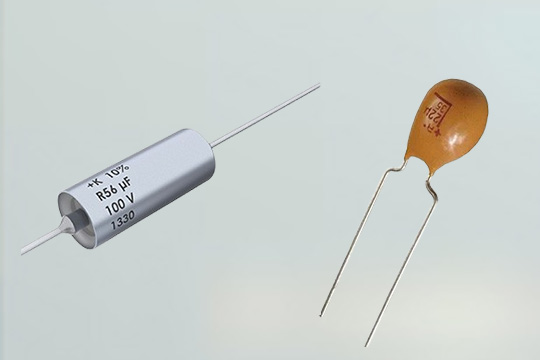

Electronic Devices:

Tantalum foil is essential in making small but powerful capacitors and resistors found in everyday electronics like smartphones, laptops, and car electronics.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Energy and Research:

It’s used in solar cells, catalysis, and battery research. The foil is part of innovative processes like using sunlight to split water into hydrogen and oxygen.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Laboratory Equipment:

Tantalum foil’s biocompatibility makes it safe for surgical tools and implants, including those used in orthopedics.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

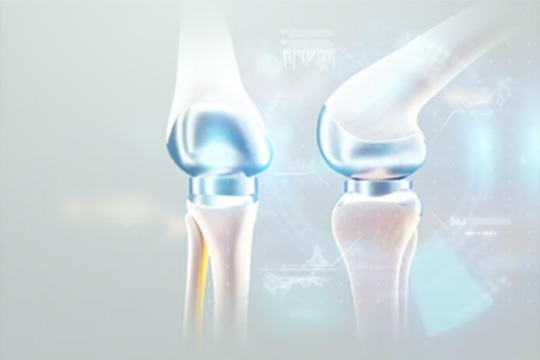

Medical Field:

Tantalum foil’s biocompatibility makes it safe for surgical tools and implants, including those used in orthopedics.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Heat Insulation and Vacuum Furnaces:

Its thermal stability is ideal for applications like lining vacuum furnaces and in heat insulation.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Aerospace and Automotive:

The foil’s strength and resistance to corrosion benefit the aerospace and automotive sectors, where durable materials are crucial.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Manufacturing Processes for Tantalum Foil

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]

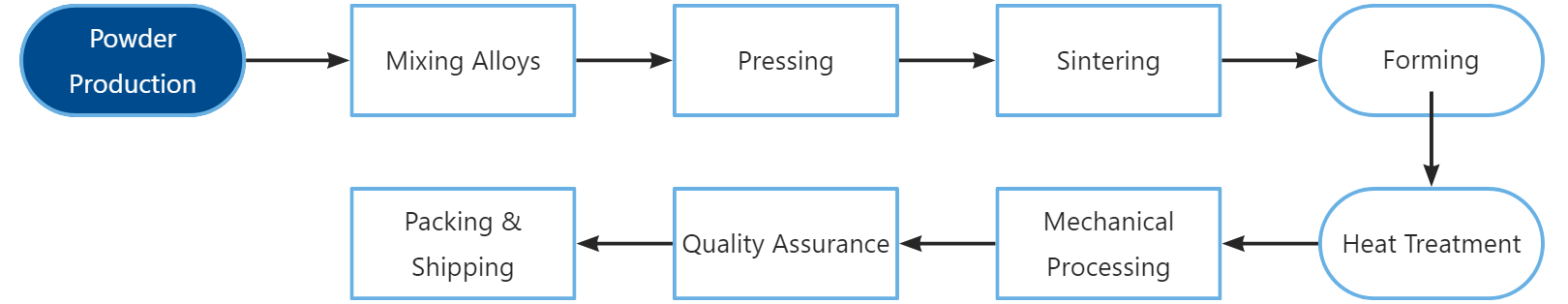

Advanced Powder Production

ARS Metal uses advanced chemical reduction to create ultra-pure, uniform metal powders. This process is key for high-quality metal products.

Mixing Alloys

Our alloy mixing process is characterized by meticulous precision. This creates alloys with unmatched performance and reliability.

Precision Pressing and Shaping

Using state-of-the-art pressing techniques, we mold our metal powders into desired shapes. Our technology excels in producing complex geometries with high precision.

Cutting-Edge Sintering Process

Our sintering process employs advanced technology. It bonds powder grains effectively, creating dense and robust sinter blocks. This step is crucial for the durability of our products.

Forming for Enhanced Durability

We use unique hot-rolling and cold-rolling processes to increase material density and strength. Our process ensures our tantalum foils can withstand rigorous applications.

Heat Treatment – Annealing

Our heat treatment annealing process is tailored to each product. It fine-tunes the mechanical properties of the metal, ensuring ease of subsequent processing and optimal performance.

Precision Mechanical Processing

ARS Metal offers specialized mechanical processing. Our services include turning, milling, grinding, cutting, joining, and coating. We focus on precision and quality in every step.

Final Product Inspection

Inspect the final Tantalum foil, including dimensional measurements, surface inspection, chemical composition analysis, etc. This ensures that the final product meets specifications.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Foil: A Comprehensive Guide for Buyer

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Foil: A Comprehensive Guide for Buyer

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

What is Tantalum Foil? A Brief Overview

Tantalum foil is a thin sheet made from tantalum metal, known for its high melting point, corrosion resistance, and excellent conductivity. The process of making this foil involves rolling tantalum into thin sheets, which can be used in a variety of applications.

Unique Properties of Tantalum Foil

High Corrosion Resistance: Tantalum foil resists corrosion from acids and other harsh chemicals, making it ideal for chemical processing environments.

High Melting Point:

With a melting point of around 2996°C, tantalum tubes maintain structural integrity in high-temperature applications.

Biocompatibility:

Tantalum is known for being biocompatible, meaning it is safe for use in medical applications. Tantalum foil is often used in the medical field for implants and surgical instruments

Excellent Conductivity:

The foil is an excellent conductor of electricity, making it a preferred material in the production of electronic components.

Ductility and Malleability:

Despite its strength, tantalum foil is also ductile and malleable. It can be easily formed into different shapes and sizes without losing its integrity.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Grades of Tantalum Foil

Tantalum foil comes in various grades, each suited for specific applications. Understanding these grades helps in selecting the right type of foil for your needs.

| Grade | Description | Main Applications |

|---|---|---|

| Grade R05200 | Unalloyed tantalum, vacuum-arc melted or electron-beam melted. | Ideal for reactor linings, heat exchangers, and other components exposed to corrosive substances. |

| Grade R05400 | Unalloyed tantalum, sintered before processing. | Commonly used in electronic components like capacitors and resistors |

| Grade R05255 | Tantalum alloyed with 10% tungsten, offering enhanced strength and higher melting point. | Utilized in aerospace and military applications due to its increased strength and thermal resistance. |

| Grade R05252 | A blend of tantalum with 2.5% tungsten, balancing ductility and strength. | Suitable for furnace parts and heat shields, especially where thermal stability and strength are critical. |

| Grade R05240 | A mix of tantalum and 40% niobium, offering excellent corrosion resistance and greater mechanical strength. | Primarily used in superconducting alloys and in the medical field for implants and surgical tools. |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Quality Control: Tantalum Foil Testing

” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”2/3″][vc_column_text css=””]Making sure tantalum foil is of top quality is very important because it’s used for important jobs in many industries. Quality checks and tests are a big part of making the foil. Let’s look at the main ways we test and control the quality of tantalum foil:

Visual Inspection:

Surface Check: Each foil is visually inspected for any surface imperfections such as scratches, pits, or irregularities. Dimensional Accuracy: The thickness, width, and length of the foil are measured to ensure they meet specified tolerances.

Chemical Analysis:

Purity Testing: To confirm the chemical composition and purity of the tantalum, tests like X-ray fluorescence (XRF) and inductively coupled plasma (ICP) are conducted. Trace Elements Analysis: Identifying trace elements is crucial to ensure the foil’s suitability for sensitive applications, especially in electronics and medical fields.

Mechanical Property Testing:

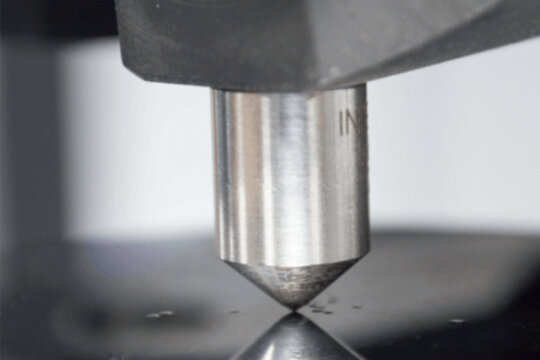

Tensile Strength Test: Determines the foil’s strength by measuring its resistance to breaking under tension. Elongation Measurement: Assesses the ductility of the foil, or how much it can stretch before breaking.

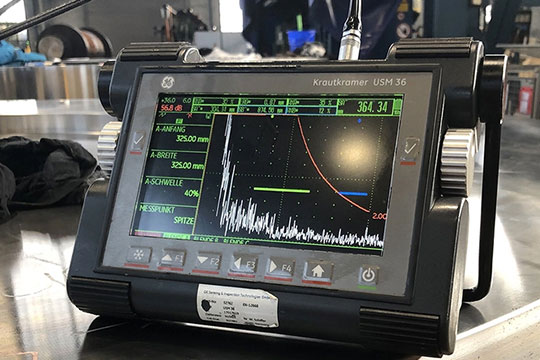

Non-Destructive Testing (NDT):

Ultrasonic Testing: Ultrasonic waves are used to detect internal flaws or inhomogeneities. Radiographic Testing: X-rays or gamma rays are used to inspect the internal structure of the tubes, identifying any internal defects.

Corrosion Resistance Testing:

The foil is exposed to various corrosive agents to ensure its resistance, a key property for its use in chemical processing and medical devices.

Thickness Measurement:

Using micrometers or other precise instruments, the exact thickness of the foil is verified, as it is a critical factor in many applications.

Certification and Documentation:

After passing all tests, the foil is certified. A report is provided to the buyer detailing the tests conducted and their results, ensuring traceability and quality assurance.

[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Non-Destructive Testing (NDT)

[/vc_column_text][/vc_column][/vc_row]