Spherical tungsten powder is a vital material widely used in various high-performance applications. Its unique properties, including high density, excellent thermal and electrical conductivity, and impressive melting point, make it the preferred choice for industries such as aerospace, defense, and additive manufacturing. This metal powder is produced through atomization methods, resulting in uniformly round particles that are essential for achieving consistent performance in advanced technologies.

In today’s fast-paced technological landscape, the demand for reliable materials like spherical tungsten powder continues to rise. Industries utilize this powder for its capabilities in creating high-density alloys, radiation shielding, and even components in microelectronics. The characteristics of this material not only enhance product performance but also contribute to innovations across sectors.

The growing interest in additive manufacturing further underscores the importance of spherical tungsten powder. As more businesses explore 3D printing applications, understanding its benefits and uses becomes crucial for staying competitive. By examining the properties and applications of this exceptional material, one can gain insight into its role in shaping the future of technology.

Properties Of Spherical Tungsten Powder

Spherical tungsten powder possesses unique properties that enhance its suitability for various applications. Understanding its physical characteristics and chemical properties is essential for evaluating its performance in industrial settings.

Physical Characteristics

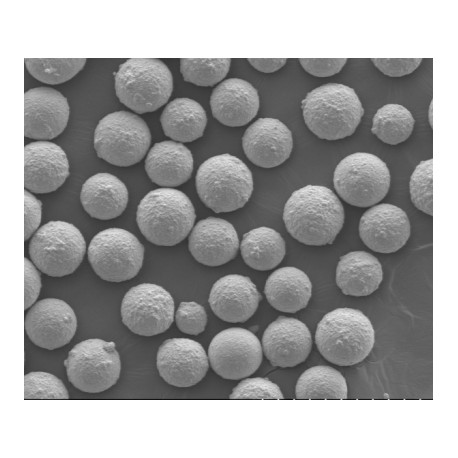

Spherical tungsten powder is known for its highly uniform particle shape, which enhances flowability and packing density. The particles are typically produced with diameters ranging from 1 to 100 micrometers.

The density often exceeds 18.5 g/cm³, making it one of the densest metals available. It has a very high melting point of approximately 3,422°C, allowing it to withstand demanding high-temperature applications.

Additionally, its spherical shape results in reduced surface area compared to other powder forms, which contributes to improved sintering and compaction behavior.

Chemical Properties

Chemically, spherical tungsten powder is highly stable and resistant to oxidation when exposed to air at lower temperatures. It maintains its integrity in various environmental conditions.

The material exhibits excellent thermal and electrical conductivity, which are crucial for applications in electronics and microelectronics.

With a minimal level of impurities, high-purity spherical tungsten powder is preferred for demanding applications. The incorporation of post-processing treatments can further enhance its magnetic and bonding properties, making it highly versatile.

Production Methods

The production of spherical tungsten powder employs various established techniques, each with unique advantages and considerations. Understanding these processes is essential for evaluating their respective effectiveness and applications in different industries.

Overview Of Manufacturing Processes

Spherical tungsten powder can be produced using several methods, including:

- Gas Atomization: This method involves melting tungsten and using high-pressure gas to atomize it into fine droplets, which solidify into spherical particles. It offers high purity and excellent sphericity.

- Plasma Spheroidization: Tungsten powder is subjected to plasma heat, resulting in the melting and reforming of its particles into spherical shapes. It is known for producing highly uniform particles.

- Mechanical Alloying: This involves repeated welding, fracturing, and re-welding of powder particles under high-energy conditions. While it can produce spherical shapes, it may not achieve the same level of uniformity as atomization techniques.

Each method offers distinct benefits regarding particle size, shape, and application suitability.

Comparison Of Methods

| Method | Advantages | Limitations |

|---|---|---|

| Gas Atomization | High purity, excellent sphericity | High equipment cost |

| Plasma Spheroidization | Uniform particles, good control over size | Complex equipment and process |

| Mechanical Alloying | Cost-effective, can produce specialized alloys | Lower sphericity and surface quality |

Gas atomization tends to be the most widely preferred method due to its efficiency and ability to produce consistent and high-quality particles. Plasma spheroidization also provides valuable outcomes, particularly in applications requiring precise size control. Mechanical alloying, while less optimal for sphericity, remains relevant due to its cost benefits.

Applications Of Spherical Tungsten Powder

Spherical tungsten powder has found diverse applications across multiple industries due to its unique properties such as high density, excellent flowability, and superior mechanical characteristics. Its versatility supports critical functions in various advanced technologies.

Use In Additive Manufacturing

In additive manufacturing, spherical tungsten powder serves as a key raw material for 3D printing processes. Its spherical shape enhances flowability, which is essential for consistent layer deposition and part integrity. The powder is often used in selective laser melting (SLM) and electron beam melting (EBM) techniques.

These methods create complex geometries and intricate designs that are difficult to achieve with traditional machining. The high melting point of tungsten allows manufacturers to create parts suitable for extreme environments, including high-temperature applications. The resulting components are not only robust but also possess high dimensional accuracy.

Role In Electronics And Electrical Contacts

Spherical tungsten powder plays a significant role in electronics, particularly in electrical contacts and microelectronic applications. Its excellent electrical and thermal conductivity makes it an ideal choice for targets and filaments in vacuum technology and semiconductor manufacturing.

This powder is also utilized in the production of components that require high reliability and performance, such as those in military and aerospace applications. The ability to maintain performance under difficult conditions adds to tungsten’s allure in these sectors. Therefore, manufacturers often turn to spherical tungsten for critical electronic applications that demand precision and durability.

Applications In Aerospace And Defense Industries

In the aerospace and defense sectors, spherical tungsten powder is employed for high-performance components that endure extreme conditions. The automotive industry benefits from its use in high-performance engines and braking systems, where high thermal stability is crucial.

Components made from this powder are known for their ability to withstand high temperatures without deforming. This characteristic is vital for applications such as turbine blades, nozzle components, and even armor in defense technologies. The high density of tungsten contributes to enhanced performance and safety, making it a preferred material in these industries.

Other Emerging Uses

Beyond traditional applications, spherical tungsten powder is gaining traction in emerging fields such as thermal spraying and coatings. Its flowability ensures a uniform and dense coating, leading to improved wear resistance.

In powder metallurgy, the powder undergoes sintering processes where it demonstrates predictable shrinkage and consolidation. This quality is critical for producing intricate and high-density components. Furthermore, the automotive sector is exploring its use in advanced battery technologies, where high-performance materials are essential for efficiency and energy density.

Conclusion

Spherical tungsten powder is recognized for its extensive applications across various industries. Its unique properties enhance performance in critical manufacturing processes.

Key benefits include:

- High Purity: Ensures superior quality and performance.

- Uniform Particle Size: Facilitates consistent flow and packing density.

- Excellent Flowability: Improves the ease of processing and handling.

Industries such as aerospace, automotive, and biomedical benefit significantly from these attributes. The powder’s enhanced sintering properties also contribute to better mechanical characteristics in finished products.

As technology evolves, the demand for spherical tungsten powder is likely to increase. Innovations in production methods, such as advanced gas atomization, continue to enhance the material’s applicability in additive manufacturing and powder metallurgy.

Spherical tungsten powder stands out as an essential material for modern manufacturing. Its combination of performance and reliability makes it a preferred choice for engineers and designers alike.