Aluminium Powder

Aluminum powders are used for several applications such as the manufacture of slurry, explosives, and detonators. The thermit process is used to manufacture ferroalloys and specialized welding applications such as rails pyrotechnic to manufacture crackers, sparkles, and other pyrotechnic products. Products of aluminum paste, paints, and several powder components are used in automobiles. It is also used to produce different types of electronics. In addition to those uses, it is found in many other paints and sealants in the market.

Aluminium Metal powder

Where to buy aluminum powder? Various aluminum powder is sold at ARS. If you do not find the powders you need, please feel free to contact us. We can supply customized sizes and powders according to customers’ requirements.

| Grade | Product Name | Chemical Composition | Particle Size |

|---|---|---|---|

| Al-1 | Aluminum powder | Al:≥ 99.0% Other: ≤ 1.0% |

-200 mesh Custom sizes are available. |

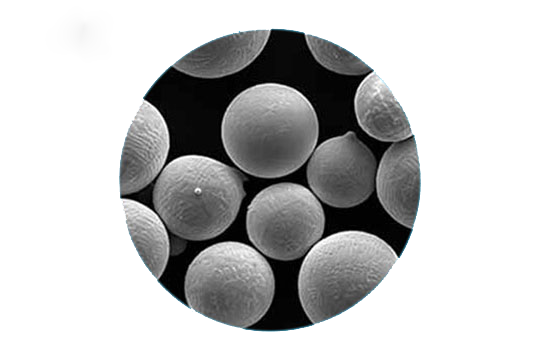

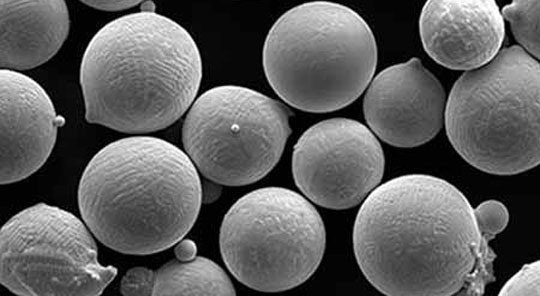

Spherical Aluminum Powder and Aluminum Based Alloy Powder

The aluminum powder is manufactured in several forms, such as flake-like particles, and granular powder (atomized aluminum). Aluminum powders are used in paints, pigments, protective coatings, printing inks, rocket fuel, explosives, abrasives, and ceramics. Furthermore, it is used in the production of inorganic and organic aluminum chemicals and as catalysts. Aluminum powder is mixed with carbon and used in the manufacture of fireworks. The coarse powder is used in aluminothermic (thermite reaction).

Grade: 2219, 2024, 6061, AlSi7Mg/ZL101, AlSi12/ZL102, AlSi10Mg/ZL104, Al-Si5Cu1Mg/ZL105

Standard: GB/T 17100, ASTM F75, ASTM F562, GB/T 1480, GB/T 5329, GB/T 8180

Shape: Spherical, Ψ0≥0.85

Appearance: Gray

3D Printing Application: SLM, LMD

Other Applications: PM, MIN, HIP, SP, Welding repair

Package: Vacuum packaging (Aluminum foil bag) or argon-filled protective packaging (Aluminum bottle)

Mechanical Properties of AlSi10Mg Powder

| Grade | Mechanical Properties | ||

|---|---|---|---|

| σb(MPa) | σ0.2(MPa) | δ(%) | |

| AlSi10Mg | 280-350 | 170-220 | 8-18 |

| ≥300 | ≥170 | ≥3.5 | |

Chemical Composition of Aluminum-Based Alloy Powder

| Chemical Composition (wt%) |

Grade | ||||||

|---|---|---|---|---|---|---|---|

| AlSi10Mg/ZL104 | AlSi12/ZL102 | AlSi7Mg/ZL101 | 7A04 | 2A12 | 2A14 | ||

| Si | 10-11 | 11-13 | 6.5-7.5 | 0.5 | 0.5 | 0.6-1.2 | |

| Mg | 0.4-0.45 | ≤0.1 | 0.25-0.45 | 1.8-2.8 | 1.2-1.8 | 0.4-0.8 | |

| Fe | 0.14-0.55 | ≤0.25 | 0.5 | 0.5 | 0.7 | ||

| Cu | <0.05 | ≤0.3 | 1.4-2.0 | 3.8-4.9 | 3.9-4.8 | ||

| Mn | <0.01-0.45 | ≤0.1 | 0.2-0.6 | 0.3-0.9 | 0.4-1.0 | ||

| Al | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | |

| Ni | <0.01-0.05 | 0.1 | 0.1 | ||||

| Zn | <0.01-0.1 | ≤0.2 | 5-7 | 0.3 | 0.3 | ||

| Pb | <0.01-0.05 | ≤0.02 | |||||

| Sn | <0.01-0.05 | ≤0.02 | |||||

| Ti | <0.01-0.15 | 0.1 | 0.15 | 0.15 | |||

| O | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | |

| Cr | 0.1-0.25 | ||||||

| Res Each | 0.05 | 0.05 | 0.05 | ||||

| Res Total | 0.1 | 0.1 | 0.1 | ||||

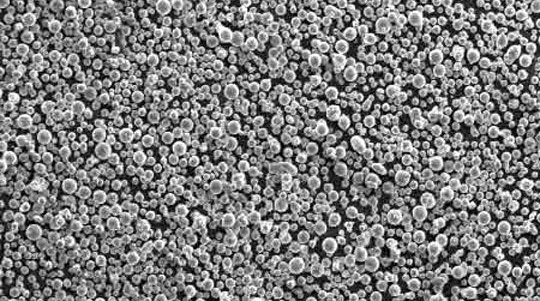

Fine Spherical Aluminum Powder

| Grade | Particle Size (um) | Activated Aluminium (≥%) | Impurity Content ≤% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Fe | Si | Cu | Mg | Zn | H2O | Total Impurities | |||

| ARS0# | ≥30 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| ARS1# | 26-29 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 24-26 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 21-24 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| ARS2# | 19-21 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 17-19 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 15-17 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| ARS3# | 13-15 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 11-13 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 9-11 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 8-10 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| ARS4# | 7-8 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 6-7 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 5-6 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 4-5 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| ARS5# | 3-4 | 98.0 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 |

| 2-3 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

| 1-2 | 0.05 | 0.015 | 0.001 | 0.001 | 0.017 | 0.1 | 0.15 | ||

Characteristics of Fine Spherical Aluminum Powder

Applications of Fine Spherical Aluminum Powder

Steelmaking deoxidizer

Crystal fiber

Titanium dioxide

The thermal spraying powder

Ceramic

Refractory (magnesia carbon brick)

Solar energy electronic pastes

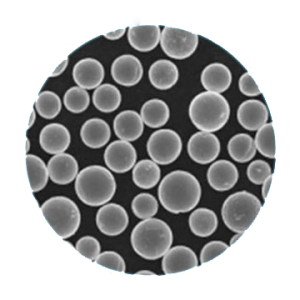

Fine Spherical High Pure Aluminum

The product’s specifications and component

| Grade | Particle Size (um) | Activated Aluminium (≥%) | Impurity Content ≤% (PPM) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Fe | Si | Zn | Ti | Cr | Ni | Co | C | H2O | |||

| ARS0# | ≥30 | 99.9 | 50 | 150 | 150 | 30 | 30 | 20 | 50 | 50 | 30 | 100 |

| ARS1# | 26-29 | 99.9 | 50 | 150 | 150 | 30 | 30 | 20 | 50 | 50 | 30 | 100 |

| 24-26 | ||||||||||||

| 21-24 | ||||||||||||

| ARS2# | 19-21 | 99.9 | 50 | 150 | 150 | 30 | 30 | 20 | 50 | 50 | 30 | 100 |

| 17-19 | ||||||||||||

| 15-17 | ||||||||||||

| ARS3# | 13-15 | 99.9 | 50 | 150 | 150 | 30 | 30 | 20 | 50 | 50 | 30 | 100 |

| 11-13 | ||||||||||||

| 9-11 | ||||||||||||

| 8-10 | ||||||||||||

| ARS4# | 7-8 | 99.9 | 50 | 150 | 150 | 30 | 30 | 20 | 50 | 50 | 30 | 100 |

| 6-7 | ||||||||||||

| 5-6 | ||||||||||||

| 4-5 | ||||||||||||

| ARS5# | 3-4 | 99.9 | 50 | 150 | 150 | 30 | 30 | 20 | 50 | 50 | 30 | 100 |

| 2-3 | ||||||||||||

| 1-2 | ||||||||||||