[vc_row][vc_column][vc_column_text]Enhance Your Products with Our Superior Tantalum Powder

Boost your business with our high-quality tantalum powder, known for its outstanding strength and excellent ductility. This unique combination provides your products with both toughness and flexibility.

What makes our tantalum powder special? It’s the precision in our manufacturing and our strict quality control standards. This commitment ensures a product that’s reliable and performs exceptionally well.

We offer two main varieties: ‘Capacitor Tantalum’ for advanced electronics and ‘Metallurgical Tantalum’ for strong structural applications. Choose our tantalum powder to improve the quality and efficiency of your products. Let’s take your manufacturing to the next level today!

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Tantalum Powder Specifications” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

| Formula: | Ta |

| Purity: | 99.9% – 99.99% |

| Particle Size: | -60 mesh, -150 mesh or -325 mesh (Custom sizes available) |

| CAS Number: | CAS-7440-25-7 |

| Grade: | Metallurgical Grade, Capacitor Grades |

| Appearance: | Dark grey metallic powder |

| Melting Point: | 3017°C / 5463°F |

| Boiling Point: | 5458°C / 9856°F |

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”32251″ img_size=”full” alignment=”center” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Capacitor Grade Tantalum Powder

Physical and Chemical Properties

| Bulk Density | Average Particle Size | Impurities (ppm) < | |

|---|---|---|---|

| g/cm3 | μm | O | N |

| 1.8-3.5 | 5.0-9.5 | 1600 | 60 |

| 1.5-3.0 | 3.5-6.0 | 2200 | 150 |

| 1.5-2.5 | 3.0-6.0 | 2000 | 150 |

| 1.5-2.5 | 3.0-5.5 | 2200 | 150 |

| 1.3-2.0 | 2.0-4.5 | 2200 | 200 |

| 1.5-2.0 | 2.0-4.0 | 2500 | 300 |

| 1.5-2.0 | 2.0-4.0 | 2500 | 300 |

| 1.3-2.0 | 1.5-3.5 | 2800 | 400 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Electrical Properties

| Detecting Condition | Standard | ||||

|---|---|---|---|---|---|

| Briquetting Weight | Briquetting Density | Sintering Condition | Energized Voltage/Test Voltage | Capacitance | Dc Leakage |

| ≤ | |||||

| 2 | 6.5 | 1850/30 | 240/170 | 5000 | 6×10-4 |

| 1 | 5.5 | 1750/30 | 200/140 | 800 | 4.5×10-4 |

| 0.2 | 5.5 | 1750/30 | 200/140 | 8000 | 4×10-4 |

| 1 | 5.5 | 1700/30 | 160/112 | 10000 | 4×10-4 |

| 0.5 | 5 | 1600/30 | 160/112 | 15000 | 5.5×10-4 |

| 0.15 | 5 | 1500/30 | 140/98 | 20000 | 5×10-4 |

| 0.15 | 5 | 1450/30 | 100/70 | 30000 | 5×10-4 |

| 0.15 | 5 | 1400/30 | 70/49 | 40000 | 5×10-4 |

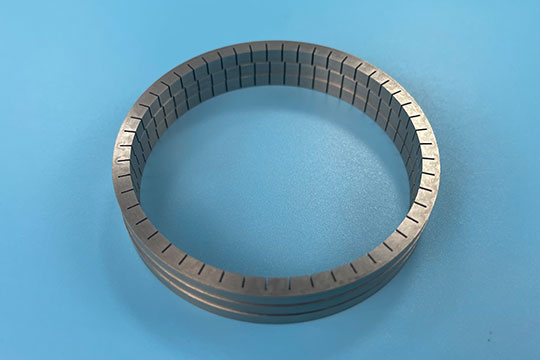

Metallurgical Grade Tantalum Powder

Grades and main content

| Grade | FTa-01 | FTa-02 | FTa-1 | |

|---|---|---|---|---|

| Main Content | Ta, %, Minimum | 99.95 | 99.95 | 99.95 |

| Impurity Content, %,max |

O | 0.100 | 0.120 | 0.180 |

| C | 0.005 | 0.005 | 0.008 | |

| N | 0.005 | 0.005 | 0.008 | |

| H | 0.003 | 0.003 | 0.003 | |

| Fe | 0.004 | 0.004 | 0.005 | |

| Ni | 0.003 | 0.003 | 0.005 | |

| Cr | 0.003 | 0.003 | 0.005 | |

| Nb | 0.003 | 0.003 | 0.005 | |

| W | 0.002 | 0.002 | 0.002 | |

| Mo | 0.001 | 0.001 | 0.002 | |

| Si | 0.003 | 0.003 | 0.005 | |

| Mn | 0.001 | 0.001 | 0.001 | |

| Ti | 0.001 | 0.001 | 0.001 | |

| Fsss(m) | 3.0-10.0 | 3.0-10.0 | 3.0-10.0 | |

| Sieve Mesh | -80 | -80 | -80 | |

| Application | Tantalum processing and alloying additives | |||

Physical Properties

| Bulk Density (g/cm3) | Average Particle Size (μm) |

|---|---|

| 5.0-7.5 | 6.0-13.0 |

| 4.5-7.0 | 6.0-12.0 |

| 3.5 -7.0 | 5.0-12.0 |

| 3.5-7.0 | 5.0-12.0 |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_empty_space][vc_custom_heading text=”Tantalum Powder Applications” font_container=”tag:h2|text_align:center” css=””][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

Tantalum Capacitors

Compact and stable, tantalum powder is ideal for capacitors in small, high-reliability electronics, like medical devices and telecoms.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Tantalum Mill Products

Tantalum powder produces corrosion-resistant mill products, essential for harsh conditions in chemical processing and aerospace.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Tantalum Sputtering Targets

Crucial for semiconductor manufacturing, these targets create uniform, corrosion-resistant films in high-performance electronics.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_column_text css=””]

3D Printing

Tantalum’s biocompatibility makes it perfect for medical 3D printing, offering personalized, durable implants.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Electronics Manufacturing

Vital in resistors and circuit boards, tantalum ensures reliability and longevity in computers and smartphones.[/vc_column_text][/vc_column][vc_column width=”1/3″][vc_column_text css=””]

Alloy Additives

Tantalum enhances other metals, used in high-stress environments like jet engines and nuclear reactors for improved strength and heat resistance.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_cta h2=”Types of Tantalum Powder and Their Production Technology” txt_align=”center” add_button=”bottom” btn_title=”CONTACT US” btn_color=”primary” btn_align=”center” css=”” btn_link=”url:https%3A%2F%2Flydiac51.sg-host.com%2Fcontact-us%2F”]

Medium Voltage Tantalum Powder

Medium-voltage tantalum powder is essential for certain capacitors (32-40V). It’s made using advanced techniques, not just basic methods. This powder is gaining popularity in capacitor manufacturing.

We’ve upgraded our production to include high-temperature sintering and hydrogen crushing. This results in flaked tantalum powder. Though more costly and complex, this powder is crucial. It has better physical properties for medium-voltage capacitors.

High Voltage Tantalum Powder

High-voltage tantalum powder is for capacitors needing 50-75V. It has bigger grains than medium-voltage powder. This helps it handle higher voltages and stress better.

Our high-voltage powder is made with extra steps, on top of the usual purification. We use ball milling and classification methods. These improve its capacitance and reduce leakage. This powder is simple, pure, and great for solid electrolyte capacitors over 50V.

Capacitor Grade Tantalum Powder

Capacitor-grade tantalum powder is the highest purity powder, specifically tailored for manufacturing capacitors used in critical and high-performance applications. These powders are characterized by their ultra-fine grain size, high surface area, and exceptional purity, which are vital for achieving high capacitance per unit volume.

Our capacitor-grade tantalum powders, produced using the sodium reduction method, are perfect for making capacitors with voltages from 4V to 40V. It suits high-quality chip-type, dipped, and polymer capacitors. It offers benefits like good moldability, high capacitance, low leakage, and resistance.

Metallurgical Grade Tantalum Powder

Metallurgical-grade tantalum powder is designed for industrial use. This powder is primarily used in tantalum products or metal alloys. It helps improve the strength and resistance of these alloys.

ARS Metal uses advanced chemical reduction to create ultra-pure, uniform tantalum powders. So we can offers tantalum in multiple forms includes sheets, rods, bars, and wires.

[/vc_cta][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

What is Tantalum Powder: A Comprehensive Guide for Buyer

What is Tantalum Powder? A Brief Overview

Tantalum powder is the finely ground version of elemental tantalum, distinguished by its steel-gray color. It is denoted by the chemical symbol ‘Ta’ and plays a crucial role in various industrial applications. Tantalum, positioned in Group VB of the periodic table, has an atomic number of 73 and an atomic weight of 180.9479. It forms a body-centered cubic crystal structure.

The hardness of tantalum powder is relatively low, and it is closely linked to the oxygen content in the material. In its annealed state, pure tantalum shows a Vickers hardness of around 140HV. One of its most significant properties is the high melting point, reaching approximately 2995°C, which makes it valuable for high-temperature applications.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text css=””]

Unique Properties of Tantalum Powder

Corrosion Resistance: A Lasting Advantage

Tantalum powder excels in resisting corrosion, a crucial factor for products exposed to harsh conditions. This resistance extends the life and reliability of your products, ensuring performance in various environments.

High Melting Point for Extreme Durability

With a melting point among the highest of metals, tantalum offers exceptional durability. This feature is vital for applications in high-temperature scenarios, guaranteeing consistent performance where other materials might falter.

Electrical Conductivity: A Boost for Electronics

The excellent electrical conductivity of tantalum powder makes it a preferred choice for electronic components. Integrating this material means enhancing the efficiency and reliability of your electronic products.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””] [/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Customizable Particle Sizes for Tailored Solutions

With the availability of various particle sizes, tantalum powder can be customized to meet the specific demands of your projects. This adaptability ensures you get the most suitable material for your application.

Quality Control: Tantalum Powder Testing

At our company, we take the quality of our Tantalum Powder seriously. It’s not just about meeting industry standards – it’s about exceeding them. From receiving raw materials to the final product, we ensure excellence. Here’s an overview of the quality testing process:

Chemical Composition Testing

Consistency in chemical composition is key. We use EDX (Energy Dispersive X-ray Spectroscopy). This helps us analyze the elemental composition of the powder.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_empty_space][vc_empty_space][vc_column_text css=””]

Purity Testing

Purity is vital for tantalum powder. We use advanced methods like ICP-MS and XRF. These detect even trace impurities. This step ensures our powder is as pure as possible.

Particle Size Analysis

Particle size affects how the powder performs. We use laser particle sizer. This accurately measures particle sizes,we ensure they meet the requirements for specific applications.

Enhanced Microstructural Inspection:

We regularly use Scanning Electron Microscopy (SEM). This lets us closely look at particle shapes and spaces. We do this to make sure everything meets our high-quality standards

Moisture Content Check

Moisture can impact the quality of the powder. We perform moisture content analysis. Techniques like thermogravimetric analysis (TGA) are used. This ensures the powder isn’t compromised by moisture.

Physical Property Assessment:

Properties like hardness and melting point are tested. These are important for the powder’s performance. They ensure the powder can handle the conditions it will face in use.

Following ASTM Standards and ISO Standards

Our testing aligns with international standards. We comply with both ASTM and ISO guidelines.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_column_text css=””]

[/vc_column_text][/vc_column][/vc_row]