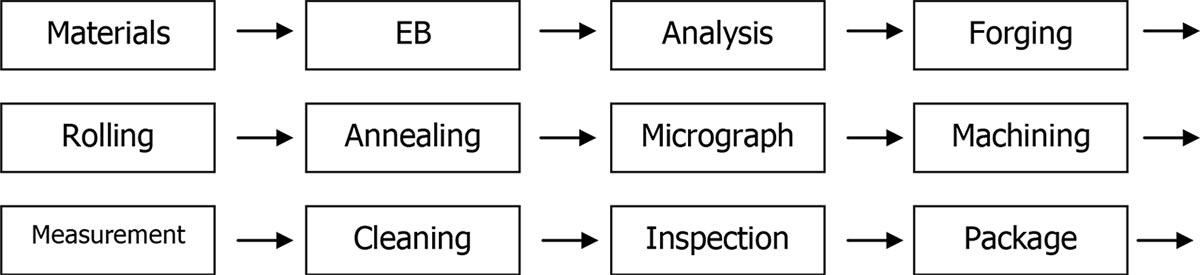

Vanadium Sputtering Target Process

Thanks to the special forming processes we use, the sputtering targets’ actual density almost reaches 100%. Our customers benefit from a faster process due to higher sputtering speeds. Our production process for Vanadium sputtering target are:

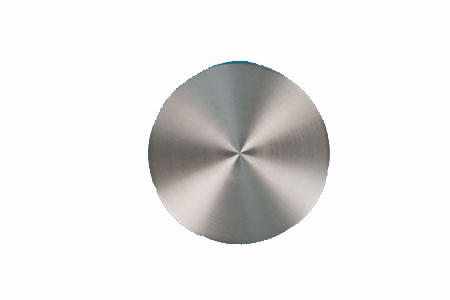

Vanadium Sputtering Target Properties

| Material | Vanadium |

|---|---|

| Chemical Formula | V |

| Atomic Weight | 50.9415 |

| Color/ Appearance | Silvery Gray, Metallic |

| Melting Point | 1890℃ |

| Thermal Conductivity | 23 W/m.K |

| Coefficient of Thermal Expansion | 8.4 x 10-6/K |

| Theoretical Density (g/cc) | 5.96 |

| Z Ration | 0.53 |

| Sputter | DC |

| Max Powder Density (Watts/Square Inch) | 50 |

| Type of Bond | Indium, Elastomer |

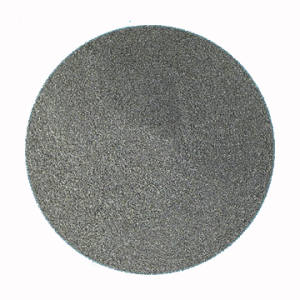

Micrograph of Vanadium Sputtering Target

Our production process’s flexibility allows adjusting the microstructure of our coating material to achieve the desired effect. If the sputtering target grains are uniformly aligned, the user can benefit from constant erosion rates and homogeneous layers.

Vanadium Sputtering Target Specifications

| Purity | 99.5%, 99.9% |

|---|---|

| Shape | Disc targets, plate targets, column targets, step targets, custom-made |

| Size | Circular: Diameter < 14inch, Thickness > 1mm; Block: Length < 32inch, Width < 12inch, Thickness > 1mm |

Chemical Composition of Vanadium Sputtering Target

The sputtering targets we produced are of high purity. The most important benefits are that the films possess an outstanding electrical conductivity level and minimized particle formation during the PVD process. Below form is a formal certificate of analysis for the 3N high purity Vanadium sputtering target.

Analytical methods:

1. Metallic elements are analyzed using ICP-OES.

2. Gas elements are analyzed using LECO.

| Element | Actual | Units | Element | Actual | Units |

|---|---|---|---|---|---|

| Na | ppm | Ni | ppm | ||

| Mg | <20 | ppm | Cu | <100 | ppm |

| Al | <20 | ppm | Zn | <50 | ppm |

| Si | ppm | As | <20 | ppm | |

| P | ppm | Zr | <20 | ppm | |

| K | <10 | ppm | Mo | <50 | ppm |

| Ca | <10 | ppm | Cd | <20 | ppm |

| Ti | ppm | Sn | <20 | ppm | |

| V | Matrix | ppm | Sb | <20 | ppm |

| Cr | <50 | ppm | Ta | <50 | ppm |

| Mn | <50 | ppm | W | <50 | ppm |

| Fe | <100 | ppm | Pb | <20 | ppm |

| Co | <100 | ppm | Bi | <20 | ppm |

| Se | ppm | Tl | <10 | ppm | |

| O | <20 | ppm | C | <20 | ppm |

| N | <20 | ppm | H | ppm | |

| S | <20 |

Vanadium Sputtering Target Applications

1. Used in semiconductor, chemical vapor deposition (CVD), physical vapor deposition (PVD) display, and optical applications.