Spherical Tantalum Powder

Spherical Niobium Powder

Hafnium Powder

Zirconium Powder

Spherical Cobalt Powder

Spherical Chromium Powder

-

Zirconia Powder

Zirconia Powder -

Other Powders

Other Powders -

Rhenium Powder

Rhenium Powder -

Spherical Silver Powder

Spherical Silver Powder -

Spherical Aluminium Powder

Spherical Aluminium Powder -

Spherical Iron Powder

Spherical Iron Powder -

Copper Powder

Copper Powder -

Spherical Nickel Powder

Spherical Nickel Powder -

Spherical Molybdenum Powder

Spherical Molybdenum Powder -

Spherical Tungsten Powder

Spherical Tungsten Powder -

Spherical Titanium Powder

Spherical Titanium Powder -

Spherical Chromium Powder

Spherical Chromium Powder -

Spherical Cobalt Powder

Spherical Cobalt Powder -

Hafnium Powder

Hafnium Powder -

Spherical Niobium Powder

Spherical Niobium Powder -

Spherical Tantalum Powder

Spherical Tantalum Powder

Advanced Refractory Solutions (ARS) provides various types of high quality spherical metal powders, the main products are spherical group powder and combined gold powder, spherical bustard and pin alloy powder, spherical group and molybdenum powder, spherical silver and ni alloy powder, spherical iron and spherical titanium alloy powder, spherical refractory and high inert alloy powder, high end rare refractory metal and composite spherical powder, and we also provide RF Plasma spheroidization service, isotropic rotating electrode atomization service, 3D printing service, hot isostatic pressing, injection molding, powder metallurgy and other technical services. These powders are designed for a variety of powder metallurgy (PM) applications such as additive manufacturing (AM), hot isostatic pressing (HIP), and metal injection molding (MIM) to ensure precision and performance in industrial manufacturing.

SPHEROIDIZATION

SPHEROIDIZATION

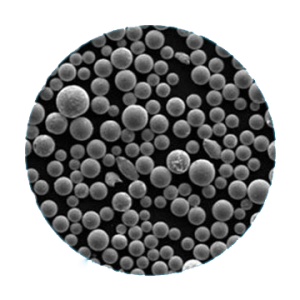

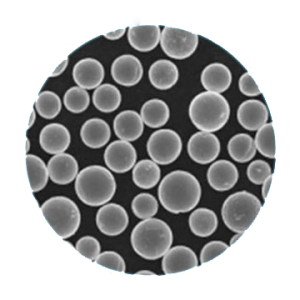

To achieve optimum flow characteristics and high packing density, an ideal Additive Manufacturing (AM) metal powder should be highly spherical in shape with no satellites. As spherical particles have minimum surface area to volume ratio this brings an added advantage in principle, of reduced surface contamination e.g. oxygen pick up. Increased particle sphericity can improve powder feeding, resulting in smoother layers, improved packing density, increased heat conduction in the powder bed and an enhanced melting profile.

Generating a component by AM, also known as metal 3D Printing, relies on building the final design through a series of many thousands of layers. Whilst different metal powders can be selected according to the required performance of the final part, reproducible behavior of the powder throughout the process is key to a successful build.

In principle, any metallic powder can be plasma treated to improve the flow and packing properties of low sphericity,irregular, sponge-like, agglomerated and angular metallic powders produced by other methods e.g. water atomization,chemical and mechanical processes, and standard gas-atomization.

Several trials have been performed for each powder feedstock to determine the optimum processing parameters.The powder samples were fully characterized after each plasma treatment trial and compared with those of thestarting feedstock.

The results demonstrate that when spheroidization parameters are optimized for the particular feedstock, particlemorphology, powder flow and packing properties are significantly improved.

Morphology and packing density have a significant effect on the quality of the powder layer and melting behavior, depending on deposition system. Plasma Spheroidization has been shown to be an effective method of controlling the shape, flow and packing characteristics to defined specifications across a range of metallic powders to deliver reliable, reproducible performance.

We have a wealth of expertise in metal AM, and extensive experience of working with leading companies within the aerospace, biomedical, and automotive industries. We utilize this knowledge and the capabilities of plasma technology to provide solutions across a wide range of industries and AM platforms.

NANOPOWDER SYNTHESIS

NANOPOWDER SYNTHESIS

We develop handled-dimensions nanoscale powders rich in purity stage in commercial volume. Our plasma approach allows us to manufacture nanomaterials including natural metals, alloys and ceramics (oxides and non-oxides).

Our accepted approach allows us to management the formula and nanostructure of our components through chemical substance allergic reactions arranged during functionality.

Each and every period of our nanopowder production is strictly controled. They may be developed and manufactured in our grow to be able to fulfill the particular demands of your respective company

NANOPOWDER SYNTHESIS

NANOPOWDER SYNTHESIS

We develop handled-dimensions nanoscale powders rich in purity stage in commercial volume. Our plasma approach allows us to manufacture nanomaterials including natural metals, alloys and ceramics (oxides and non-oxides).

Our accepted approach allows us to management the formula and nanostructure of our components through chemical substance allergic reactions arranged during functionality.

Each and every period of our nanopowder production is strictly controled. They may be developed and manufactured in our grow to be able to fulfill the particular demands of your respective company

Application

3D Printing of Tantalum Medical Metal Materials

3D Printing of Tantalum Medical Metal Materials

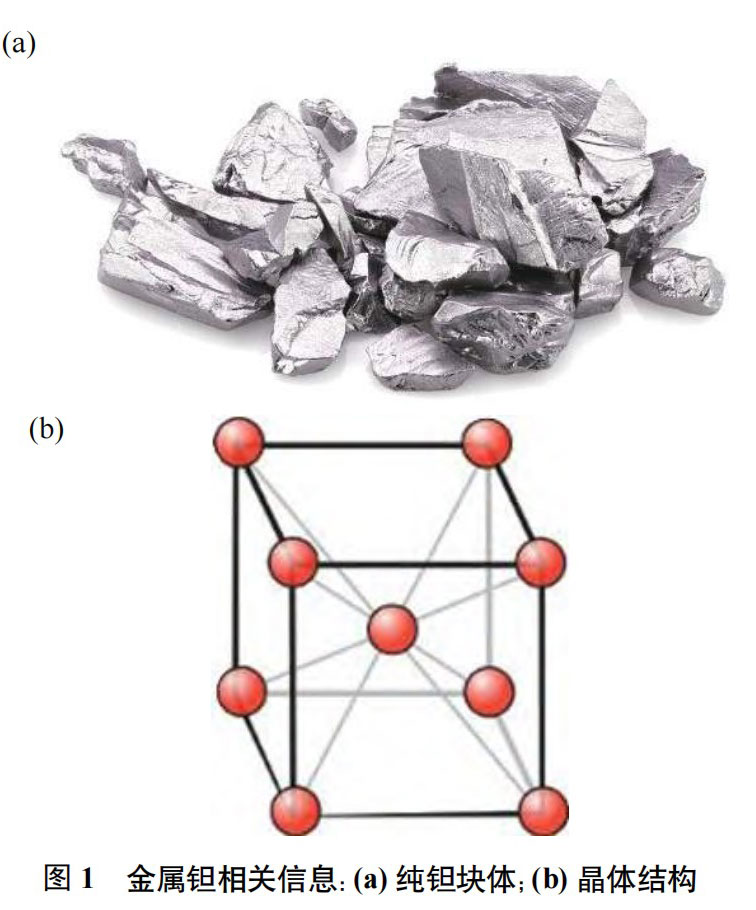

Basic Properties of Tantalum

Tantalum metal is silvery white with a density of 16.654 g/cm3. Its high density is related to relative atomic mass, atomic radius and atomic volume. The relative atomic mass of tantalum atom is about 180.95, the atomic volume is 10.9 cm³/mol, and the atomic radius is 0.146 nm. The relative atomic mass per unit atomic volume is large, so its density is high. Tantalum has a body-centered cubic lattice structure, with close arrangement of atoms and more slip systems, so tantalum has good elongation properties. The metal bonding energy between tantalum atoms is large, and the energy required to destroy the metal bonding is large, resulting in a melting point as high as 2997 °C. In addition, tantalum has a low expansion coefficient of about 7×10–6 ℃–1, which is lower than common metals such as gold, silver, aluminum, copper and iron.

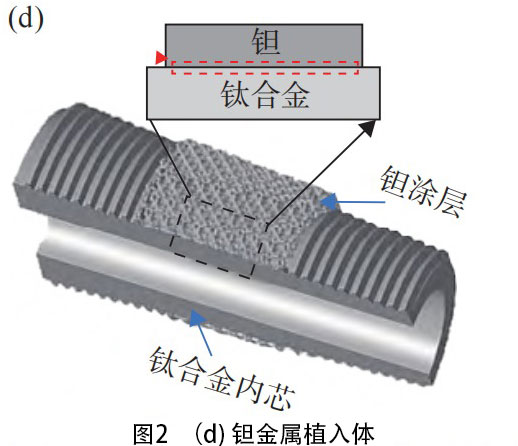

Application of Tantalum in the Medical Field

The potential of tantalum in the medical field has received widespread attention. Figure 2(d) is a medical tantalum-titanium composite material. Tantalum as a coating can improve the biocompatibility of the alloy. However, there are differences in the properties of the coating and the substrate material. The surface modified coating usually exhibits poor bonding strength, and the coating is easily damaged during use, which limits its function. In the medical industry, using tantalum as the main raw material, that is, preparing all-tantalum bone implants, is an effective way to overcome the above shortcomings. However, due to the high melting point and high affinity for oxygen of tantalum, the traditional processing method is difficult to process, and the production efficiency and material utilization rate are low, which greatly increases the preparation cost of tantalum implants and increases the burden on patients. Therefore, a new process is urgently needed to achieve efficient and accurate forming of all-tantalum bone implants.

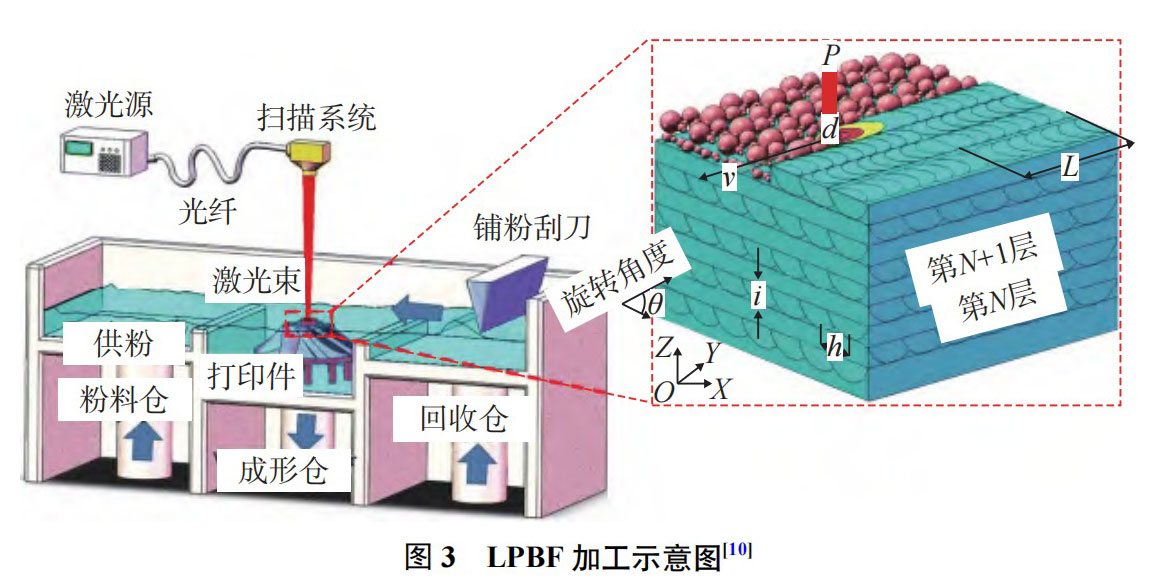

3D printing tantalum

3D printing is a new processing method. The most notable feature of this technology is that it can directly form the final three-dimensional sample according to the imported workpiece model. Laser Powder Bed Fusion (LPBF) and Electron Beam Melting (EBM) in 3D printing are often used to process tantalum implants. The schematic diagram of LPBF processing is shown in Figure 3. The LPBF processing equipment has three chambers, namely the powder chamber, the forming chamber and the recycling chamber. Metal powder needs to be added to the powder chamber in advance before printing. During processing, the powder is evenly spread in the forming chamber by a scraper, and then solidified into a pre-set shape after being melted and heated by a laser or electron beam. The powder chamber rises layer by layer, and the forming chamber descends layer by layer, and finally forms a layer by layer.

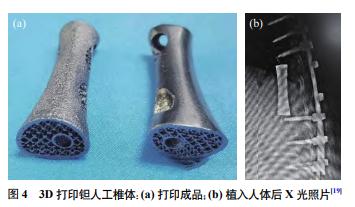

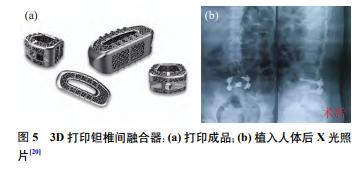

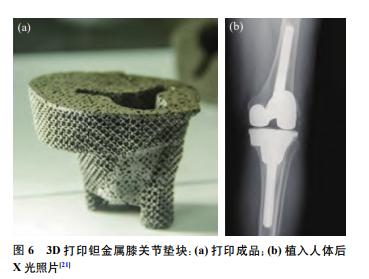

3D printing medical tantalum implant case

With the continuous improvement of medical level and the implementation of “Made in China 2025”, new preparation processes represented by additive manufacturing have promoted the vigorous development of my country’s orthopedic implant market. Since 2015, my country has become the world’s second largest consumer of bone implants. At present, bone implant products can be divided into spine, joint and trauma categories according to the use scenario, among which acetabular cups (joint implants) and intervertebral fusion cages (spinal implants) have the fastest commercial development. Bone implant manufacturing materials include metals, ceramics, polymers and carbon materials. Among them, tantalum, as a member of metal bone implants, has great development potential.

Spinal products

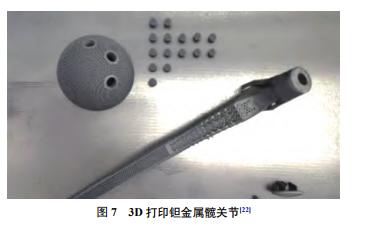

Joint products

In 2022, Zhongshan Hospital Affiliated to Dalian University performed the world’s first 3D printed tantalum metal ankle joint implant for a patient (Figure 9) [24]. The patient had talar necrosis and ankle inflammation. In order to solve the patient’s pain symptoms and restore ankle flexibility, the hospital customized a 3D printed metal tantalum ankle joint for the patient. After the implant, the patient recovered well and could walk slowly one day after the operation.

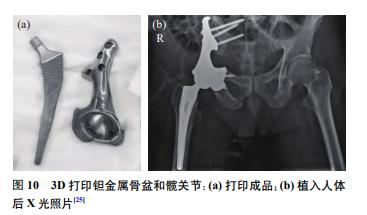

Pelvic surgery has always been one of the difficult problems in orthopedic surgery. In 2022, Zhongshan Hospital Affiliated to Dalian University performed 3D printed tantalum hemipelvis and hip prosthesis implantation for a patient with right hip deformity caused by pelvic tumor (Figure 10(a)), further broadening the application of 3D printed porous tantalum. The patient had a large damaged area and needed to remove the ilium, acetabulum, and part or all of the pubic bone and ischium. The removal and implantation surgery was difficult. The hospital customized the implant for the patient through 3D printing, which was highly matched with the defective area after the patient’s resection (Figure 10(b)), saving the implantation time.

Trauma products

In April 2019, the 3D printed trabecular tantalum stent developed by Xiangya Hospital was successfully implanted into a patient with femoral head necrosis. This was the world’s first tantalum metal stent implantation surgery (Figure 11) [26]. The top of the tantalum stent is in an arc shape at the contact point with the human bone, which is similar to the curvature of the human bone. When the stent is subjected to force, there are many contact points with the human bone, and the pressure is relatively even, which can prevent the implant from being damaged.

3D printed tantalum powder-Stardust Technology

About Stardust Technology

Stardust Technology (Guangdong) Co., Ltd. is a national high-tech enterprise specializing in the research, development, production and sales of high-end spherical powder materials in the fields of 3D printing, powder metallurgy, surface engineering, etc. The company insists on taking radio frequency plasma spheroidization powder making technology as the core, providing internationally advanced powder products and application solutions.

Medical grade spherical tantalum powder

The spherical tantalum powder produced by Stardust Technology using radio frequency plasma spheroidization technology has excellent biocompatibility and bone ingrowth characteristics, and is widely used in 3D printing of clinical medical implants such as spine, joints, and trauma. Stardust Technology is the first in China to achieve an industrial breakthrough in medical-grade spherical tantalum powder. It has jointly promoted the clinical medical application of tantalum metal with domestic first-class orthopedic hospitals and medical device companies. It has participated in the formulation of GB/T 38975-2020 Tantalum and tantalum alloy powder for additive manufacturing, GB/T 41883-2022 Powder bed fusion additive manufacturing of tantalum and composite alloys, 2 national standards, YY/T1851-2022 Medical pure tantalum powder for additive manufacturing, 1 industry standard, T/CAMDI065-2021 Additive manufacturing of tantalum metal knee prosthesis, T/CAMDI 066-2021 Additive manufacturing of tantalum metal individualized bone defect filler “and other 3 group standards, and assisted in the completion of more than 500 cases of tantalum metal clinical application, implanted prostheses include tantalum metal intervertebral fusion bone spacers, hip joints, shoulder joints, knee joints, ankle joints, etc.

PLASMA SPHEROIDIZATION

PLASMA SPHEROIDIZATION

Our plasma spheroidization system range enables both the development and industrial production of highly spherical metallic or ceramic powders, without introducing any impurities.

Starting with precursors feedstocks such as crushed, atomized and sponged powders, with sizes ranging from between 5 and 500 μm, we produce perfectly spherical powder particles.

In order to meet the specific needs of your business, from research & development to industrial production. During each stage, the plasma systems are under full computerised control. We manufacture customer proven plasma systems for both laboratory and industrial applications.

HOT ISOSTATIC PRESSING

HOT ISOSTATIC PRESSING

Hot isostatic pressing (HIP) is a manufacturing process, used to reduce the porosity of metals and increase the density of many ceramic materials. This improves the material’s mechanical properties and workability.

The process can be used to produce waste form classes. Calcined radioactive waste (waste with additives) is packed into a thin walled metal canister. The adsorbed gases are removed with high heat and the remaining material compressed to full density using argon gas during the heat cycle. This process can shrink steel canisters to minimize space in disposal containers and during transport. It was invented in the 1950s at the Battelle Memorial Institute[1] and has been used to prepare nuclear fuel for submarines since the 1960s. It is used to prepare inactive ceramics as well, and the Idaho National Laboratory has validated it for the consolidation of radioactive ceramic waste forms. ANSTO (Australian Nuclear Science and Technology Organisation) is using HIP as part of a process to immobilize waste radionuclides from molybdenum-99 production.

The HIP process subjects a component to both elevated temperature and isostatic gas pressure in a high pressure containment vessel. The pressurizing gas most widely used is argon. An inert gas is used so that the material does not chemically react. The choice of metal can minimize negative effects of chemical reactions. Nickel, stainless or mild steel, or other metals can be chosen depending on the desired redox conditions. The chamber is heated, causing the pressure inside the vessel to increase. Many systems use associated gas pumping to achieve the necessary pressure level. Pressure is applied to the material from all directions (hence the term “isostatic”).

For processing castings, metal powders can also be turned to compact solids by this method, the inert gas is applied between 7,350 psi (50.7 MPa) and 45,000 psi (310 MPa), with 15,000 psi (100 MPa) being most common. Process soak temperatures range from 900 °F (482 °C) for aluminium castings to 2,400 °F (1,320 °C) for nickel-based superalloys. When castings are treated with HIP, the simultaneous application of heat and pressure eliminates internal voids and microporosity through a combination of plastic deformation, creep, and diffusion bonding; this process improves fatigue resistance of the component. Primary applications are the reduction of microshrinkage, the consolidation of powder metals, ceramic composites and metal cladding. Hot isostatic pressing is thus also used as part of a sintering (powder metallurgy) process and for fabrication of metal matrix composites,[3] often being used for postprocessing in additive manufacturing.

POWDER METALLURGY

POWDER METALLURGY

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product.

Powder metallurgy is also used to make unique materials impossible to get from melting or forming in other ways. A very important product of this type is tungsten carbide (WC). WC is used to cut and form other metals and is made from WC particles bonded with cobalt. It is very widely used in industry for tools of many types and globally ~50,000 tonnes/year (t/y) is made by PM. Other products include sintered filters, porous oil-impregnated bearings, electrical contacts and diamond tools.

Since the advent of industrial production–scale metal powder–based additive manufacturing (AM) in the 2010s, selective laser sintering and other metal AM processes are a new category of commercially important powder metallurgy applications.