Titanium powder is a versatile material used in various industries, including aerospace, automotive, and medical applications. Understanding the safety concerns surrounding its use is crucial for anyone working with this substance. A Safety Data Sheet (SDS) for titanium powder outlines essential information such as handling procedures, potential hazards, and emergency measures, ensuring workplace safety.

Professionals need to be aware that titanium powder can pose risks, especially in its dust form, which is combustible and may cause explosions. Each SDS provides detailed guidance, including exposure limits and personal protective equipment recommendations, helping workers minimize risks effectively. Accessing the Safety Data Sheet from American Elements or Fisher Scientific proves valuable for understanding material safety.

By familiarizing themselves with titanium powder SDS, individuals can make informed decisions that prioritize safety in their operations. This knowledge fosters a safer environment and promotes responsible handling practices within various sectors that utilize this valuable metal.

Properties of Titanium Powder

Titanium powder exhibits distinct physical and chemical properties that make it suitable for various applications. Its unique characteristics impact its performance in manufacturing and engineering contexts. This section explores these properties, highlighting its significance in different uses.

Physical and Chemical Characteristics

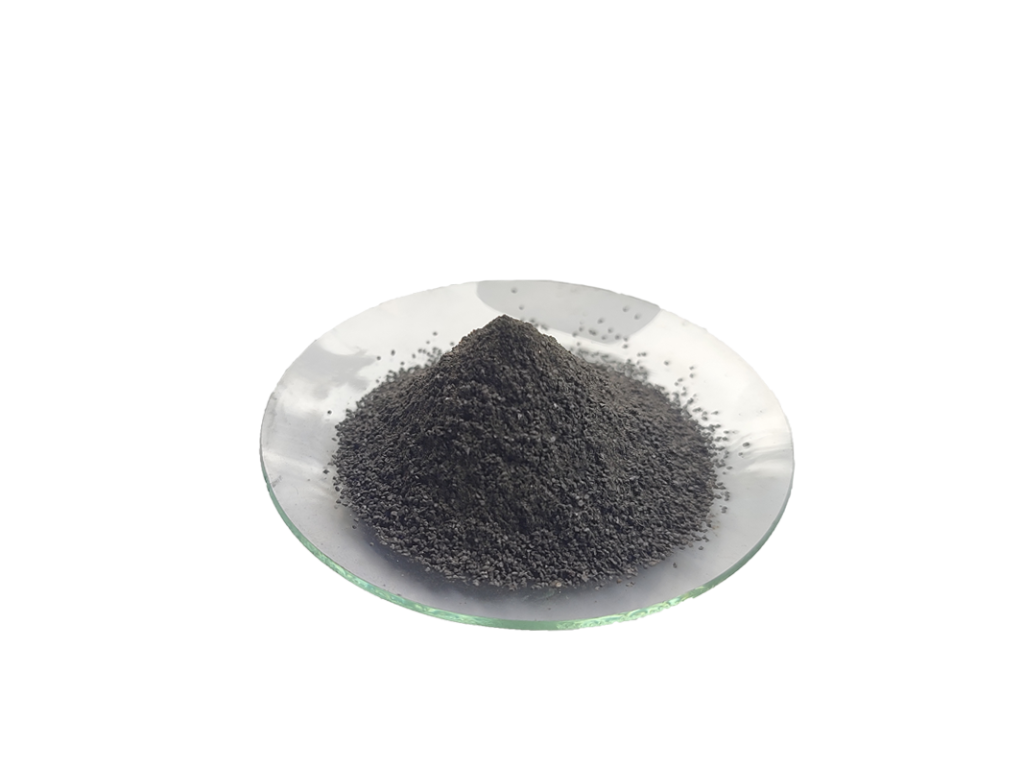

Titanium powder is known for its lightweight yet strong composition. It has a density of approximately 4.5 g/cm³, which contributes to its favorable strength-to-weight ratio. The powder is typically gray in color and has a particle size that can range from 1 to 100 micrometers, depending on the manufacturing process.

Chemically, titanium is highly resistant to corrosion, making it ideal for use in harsh environments. It maintains its properties even at high temperatures, with a melting point around 1,668°C (3,034°F). The powder can also react with oxygen at elevated temperatures, forming a titanium oxide layer that further enhances its corrosion resistance.

Common Applications in Manufacturing and Engineering

Titanium powder is widely used in additive manufacturing, particularly in 3D printing. Industries such as aerospace, automotive, and medical fields utilize titanium due to its high strength and low weight. In aerospace, components produced from titanium powder can significantly reduce the overall weight of aircraft while maintaining structural integrity.

Additionally, titanium powder is used to produce parts that require high durability and wear resistance, such as turbine blades and surgical implants. Its biocompatibility makes it suitable for medical devices, ensuring minimal adverse effects in the human body.

Comparison with Other Metal Powders

When compared to other metal powders, titanium powder stands out for its superior strength-to-weight ratio. For instance, aluminum powder, while lighter, does not offer the same mechanical strength. In contrast, steel powder provides greater strength but at a significantly heavier weight.

Moreover, titanium’s corrosion resistance surpasses that of most common metals like steel and aluminum, making it more suitable for specialized environments. The choice between titanium and other metal powders often depends on the specific requirements of the application, including weight constraints, strength requirements, and environmental conditions.

Importance of Safety Data Sheets (SDS)

Safety Data Sheets (SDS) play a crucial role in chemical safety, providing essential information about substances, including titanium powder. They ensure that users have access to important details regarding hazards and safety protocols necessary for handling and using chemicals properly.

Explanation of What an SDS Is and Its Components

An SDS is a formal document that outlines the properties, hazards, and safe handling procedures for a chemical substance. It typically includes sections such as:

- Identification: Names, manufacturers, and recommended uses.

- Hazard Identification: Classification of hazards associated with the substance.

- Composition: Information about chemical ingredients.

- First-Aid Measures: What actions to take in case of exposure.

Each section provides critical information that assists users in understanding potential risks and utilizing proper safety measures. An SDS ensures that workers are informed about the risks involved with handling materials like titanium powder, promoting safety in various applications.

Legal Requirements for SDS in the Workplace

Most jurisdictions mandate that manufacturers and importers provide SDS for chemical products. The Occupational Safety and Health Administration (OSHA) in the United States, for instance, has specific regulations under the Hazard Communication Standard.

Employers are required to:

- Maintain an SDS for each chemical used in the workplace.

- Make these sheets accessible to all employees.

- Provide training on how to read and understand SDS.

Failure to comply can result in significant fines and penalties, reinforcing the need for proper adherence to legal requirements concerning SDS.

Role of SDS in Ensuring Safe Handling and Usage of Titanium Powder

The SDS serves as a vital resource for safe handling and usage of titanium powder in various settings. By providing detailed hazard information and recommended safety precautions, it helps prevent accidents.

For example, it may specify:

- Personal Protective Equipment (PPE): Recommendations for gloves, masks, and safety goggles.

- Emergency Procedures: Instructions on dealing with spills or exposure incidents.

- Storage Guidelines: Ideal conditions for keeping titanium powder safely.

This comprehensive information allows users to minimize risks effectively, ensuring a safer working environment while utilizing titanium powder.

Key Information Found in Titanium Powder SDS

Titanium powder Safety Data Sheets (SDS) provide essential information regarding the safe management and use of the substance. The following subsections detail critical areas such as hazard identification, first aid measures, handling instructions, and personal protective equipment (PPE) recommendations.

Hazard Identification and Risk Assessment

The SDS begins with a clear identification of hazards associated with titanium powder. This may include statements regarding potential health risks, such as respiratory irritation or skin sensitization. For instance, inhalation of fine powder particles can lead to respiratory issues.

Clearly labeled hazard pictograms help indicate the classification of the substance. The document typically mentions physical hazards, including flammability and reactivity. Users should pay attention to the precautionary statements that outline the necessary actions to mitigate risks.

First Aid Measures and Emergency Response

In emergencies involving titanium powder, the SDS outlines specific first aid measures. Immediate steps include removing the affected person from exposure to the powder. If inhaled, the individual should be taken to fresh air and monitored for breathing difficulties.

For skin contact, washing the affected area gently with soap and water is recommended. If irritation persists, medical attention should be sought. The SDS further provides information on handling spills, recommending appropriate containment and cleanup procedures, ensuring that personnel are informed on emergency protocols.

Handling and Storage Guidelines

Proper handling and storage practices for titanium powder are critical for safety. The SDS emphasizes using adequate ventilation in workspaces to minimize inhalation risks. Additionally, working with the powder should be done in designated areas to avoid cross-contamination.

Containers holding titanium powder should be tightly sealed and stored in cool, dry conditions, away from incompatible materials. The SDS often specifies recommendations for bulk storage and disposal methods, reinforcing the importance of following local regulations.

Personal Protective Equipment (PPE) Recommendations

PPE is essential when working with titanium powder. The SDS outlines various protective measures, including personal protective clothing, gloves, and eye protection.

Common recommendations include:

- Respirators: To protect against inhalation of airborne particles.

- Safety goggles: For eye protection against powder splashes.

- Chemical-resistant gloves: To prevent skin contact.

The selection of appropriate PPE should be based on a thorough risk assessment of the specific working environment. Regular training and awareness are crucial for ensuring compliance with these safety recommendations.

Conclusion

Understanding the Safety Data Sheet (SDS) for titanium powder is essential for safe handling and compliance in various industries. The significance of these documents extends to regulatory adherence, risk management, and fostering a culture of safety.

Recap of the Significance of Understanding Titanium Powder SDS

Titanium powder SDS provides critical information regarding the properties, hazards, and safe handling procedures for titanium powder. This includes data on physical characteristics, potential health effects, and emergency response protocols.

Proper adherence to SDS guidelines ensures that workplaces are prepared to manage risks associated with titanium powder, promoting safer operational environments. Awareness of these elements also aids in training employees on safe practices, ultimately reducing workplace accidents and injuries.

Encouragement for Industries to Prioritize Safety and Compliance

Industries utilizing titanium powder must prioritize safety and compliance with SDS recommendations. Investing in training programs and informative resources allows employees to understand potential hazards effectively.

Establishing robust safety protocols helps mitigate risks associated with exposure or accidental releases. Organizations that embody a culture of safety not only protect their workers but also enhance their reputation and productivity. Regulatory compliance is not merely a requirement but a fundamental aspect of operational integrity.

Final Thoughts on the Future of Titanium Powder Usage and Safety Practices

As titanium powder gains traction in various applications, continuous improvements in safety practices must keep pace. The growing use of advanced materials in technology and manufacturing increases the need for rigorous SDS adherence.

Future trends in processing and application will likely lead to evolving regulations. Organizations must adapt by regularly updating their safety protocols and ensuring all personnel are informed. Emphasizing proactive safety measures will be crucial for maintaining safe environments and achieving long-term success in using titanium powders.