Tungsten carbide thermal spray powder is a vital material in modern industrial applications, known for its exceptional durability and wear resistance. This powder is primarily used to create hard surface coatings that significantly enhance the lifespan of components subjected to extreme conditions. Industries such as petrochemical, marine, and manufacturing benefit greatly from its protective qualities, which help reduce maintenance costs and downtime.

The process of thermal spraying involves applying tungsten carbide powders onto a substrate, forming a dense and tough coating that adheres strongly to the surface. This method is particularly effective in combating wear caused by erosion, abrasion, and impact, making it an essential solution for parts that face significant wear challenges. As technology advances, the applications for tungsten carbide thermal spray powder continue to expand, pushing the boundaries of performance in various fields.

Understanding the properties and advantages of tungsten carbide thermal spray powder can empower businesses to make informed decisions about material choices. With benefits like enhanced wear resistance and improved component longevity, this thermal spray powder stands out as a key player in maintaining operational efficiency and reliability in demanding environments.

Properties Of Tungsten Carbide Thermal Spray Powder

Tungsten carbide thermal spray powder is renowned for its superior hardness and wear resistance. These properties make it an excellent choice for various industrial applications where durability is paramount.

Composition And Characteristics

Tungsten carbide thermal spray powders are primarily composed of tungsten carbide (WC) combined with cobalt (Co) or nickel (Ni). The typical formulations include WC with varying percentages of cobalt or nickel, such as WC-12Co or WC-10Ni, which influence the characteristics of the coatings.

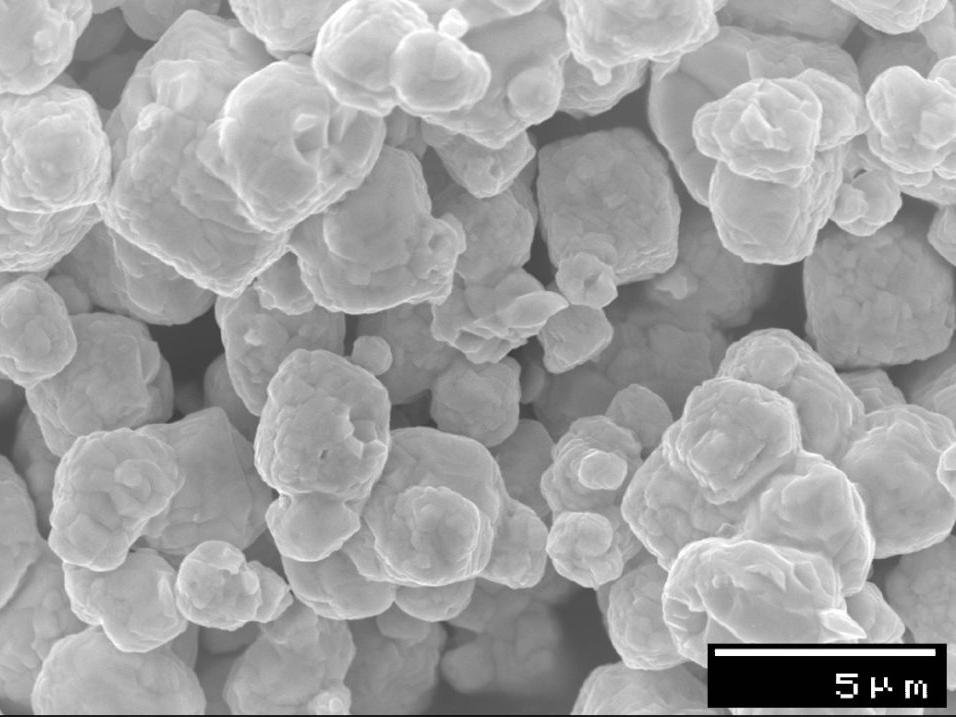

The agglomerated and sintered form of these powders results in dense, hard particles that can withstand extreme conditions. They exhibit exceptional toughness, thermal stability, and resistance to corrosion and oxidation. The coatings formed using these powders maintain their performance capabilities at elevated temperatures, making them suitable for demanding environments.

Advantages Of Using Tungsten Carbide In Thermal Spray Applications

The use of tungsten carbide in thermal spray applications provides several notable benefits. First, the hardness of tungsten carbide leads to excellent wear resistance, reducing the frequency of maintenance and replacement.

Additionally, coatings made from tungsten carbide powders offer superior oxidation and corrosion resistance. For instance, powders like WCT 74/20/6 protect components at temperatures up to 750°C. This durability translates into longer service life for parts subjected to harsh operating conditions.

Finally, tungsten carbide coatings can significantly enhance the performance of equipment, allowing operators to achieve better efficiency and productivity across various applications, from aerospace to manufacturing.

Comparison With Other Thermal Spray Materials

When compared to other thermal spray materials, tungsten carbide stands out due to its unique combination of properties. For example, while carbide materials excel in hardness and wear resistance, traditional ceramic coatings may offer higher thermal insulation but lack durability in mechanical wear scenarios.

In terms of cost-effectiveness, tungsten carbide powders provide a balance between performance and price. Although they may have a higher initial cost than some alternatives, their longevity and resistance to degradation often result in lower overall operational costs over time.

Tungsten carbide formulations can also compete with materials like chrome-carbides and even some high-performance metals, making them a versatile choice in industrial thermal spray coatings for specific applications.

Applications Of Tungsten Carbide Thermal Spray Powder

Tungsten carbide thermal spray powder serves a variety of industries and applications. Its unique properties make it essential for increasing wear resistance and enhancing the durability of components. This section outlines the critical applications of this material.

Industrial Applications

Tungsten carbide thermal spray powder is commonly used in various industrial settings. It is particularly effective in applications requiring high wear resistance and durability.

Key industries include:

- Mining: Components exposed to abrasive materials benefit significantly from tungsten carbide coatings, reducing maintenance costs.

- Oil and Gas: Equipment such as pump seals and valve seats use thermal spray powder to withstand harsh environments.

- Aerospace: Coatings applied to landing gears and other vital components enhance their performance and longevity.

The adoption of tungsten carbide coatings in these industries helps in minimizing downtime and increasing operational efficiency.

Protective Coatings And Wear Resistance

The primary function of tungsten carbide thermal spray powder is to provide protective coatings that mitigate wear. These coatings create a resilient layer that is resistant to abrasion, impact, and corrosion.

Benefits include:

- Extended Lifespan: Components coated with tungsten carbide can last significantly longer than those without protection.

- Cost Efficiency: Reduced replacement frequency translates into lower operational costs for businesses.

Typical uses involve coatings for:

- Cutting Tools: Enhanced performance and lifespan in machining operations.

- Turbine Parts: Protection against wear and fatigue in high-temperature environments.

Implementing these coatings leads to improved performance and reliability in critical applications.

Role In Enhancing The Lifespan Of Components

Tungsten carbide thermal spray powder plays a vital role in extending the lifespan of various components in numerous applications. By applying this material, companies can achieve substantial savings by reducing part replacement frequencies.

This enhancement is primarily due to its:

- Robustness: The hardness of tungsten carbide enables it to withstand extreme operating conditions.

- Adhesion: The ability of thermal spray coatings to bond effectively to substrates ensures long-term performance.

Components that benefit include:

- Industrial Equipment: Pumps and conveyor systems experience lower wear.

- Automotive Parts: Coatings can enhance reliability in high-stress automotive applications.

Utilizing tungsten carbide thermal spray powder ultimately leads to increased efficiency and decreased operational interruptions.

The Thermal Spray Process

The thermal spray process involves several techniques to apply coatings effectively. These methods enhance the performance characteristics of tungsten carbide powder, ensuring optimal surface quality and durability. The following details the main techniques, preparation processes, and quality control measures involved.

Overview Of Thermal Spray Techniques

Multiple thermal spray techniques are used to apply tungsten carbide coatings, including High-Velocity Oxygen Fuel (HVOF) and Plasma Spray.

- HVOF employs combustion gases to accelerate powdered material toward the substrate. This method yields a dense coating with superior wear resistance.

- Plasma Spray utilizes a plasma arc to melt the powder before it contacts the workpiece, producing coatings with high thermal and mechanical properties.

Each technique has its applications and advantages, with HVOF being particularly effective for high-performance coatings due to its reduced oxidation and porosity.

Preparation And Application Of Tungsten Carbide Powder

Before application, tungsten carbide powder must undergo meticulous preparation.

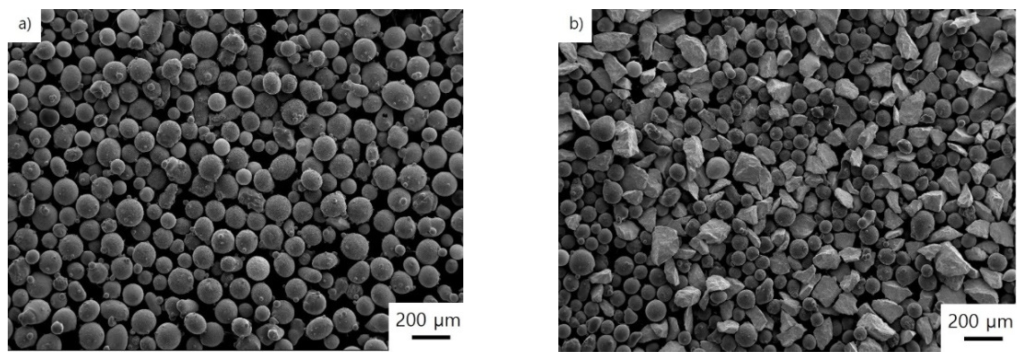

- Powder Sizing: Achieving the correct particle size is crucial for proper flow during spraying. This ensures uniform coating thickness.

- Binder Selection: Different binder materials can impact the properties of the final coating, such as toughness and wear resistance.

The application process itself involves heating the powder to its melting point to ensure bonding upon impact. The spray is directed onto the substrate, where it rapidly cools and solidifies, forming a coating that adheres tightly to the surface.

Quality Control And Performance Evaluation

Quality control in the thermal spray process is essential to ensure coating reliability.

- Visual Inspection: Initial assessments may reveal surface defects, such as cracks or poor adhesion.

- Thickness Measurement: Using tools like micrometers ensures the coating meets specified thickness requirements.

- Performance Testing: Coatings undergo wear and corrosion tests to evaluate their durability in real-world applications.

Regular monitoring and rigorous testing contribute to consistent coating performance, which is critical in industries demanding high reliability.

Conclusion

The importance of tungsten carbide thermal spray powder in various industrial applications cannot be overstated. Its unique properties contribute to enhanced wear resistance and extended lifespan of components. Advances in thermal spray technology continue to evolve, highlighting its relevance in modern engineering.

Recap Of The Significance Of Tungsten Carbide Thermal Spray Powder

Tungsten carbide thermal spray powder is crucial for industries requiring durable materials. The powder’s high hardness and resistance to abrasion make it ideal for protective coatings.

Key applications include:

- Aerospace: Protects components from wear and thermal fatigue.

- Manufacturing: Extends the life of tooling and machinery.

- Automotive: Enhances longevity of engine parts.

The ability to apply this powder using techniques like High Velocity Oxygen Fuel (HVOF) and plasma spraying ensures uniform coating. This process significantly improves the performance of machinery in harsh environments, reducing maintenance costs and downtime.

Future Trends In Thermal Spray Technology

Future trends in thermal spray technology indicate a growing focus on sustainability and efficiency. Innovations in eco-friendly materials and processes are gaining attention.

Some anticipated developments include:

- Advanced Materials: Research into alternative carbide compositions to reduce environmental impact.

- Automation: Increased use of robotics for precision in applying coatings.

- Integration with 3D Printing: Combining thermal spray with additive manufacturing to create complex geometries.

These trends promise to enhance the effectiveness of tungsten carbide coatings. As industries adopt advanced solutions, they will benefit from improved performance and cost-effectiveness in thermal spray applications.