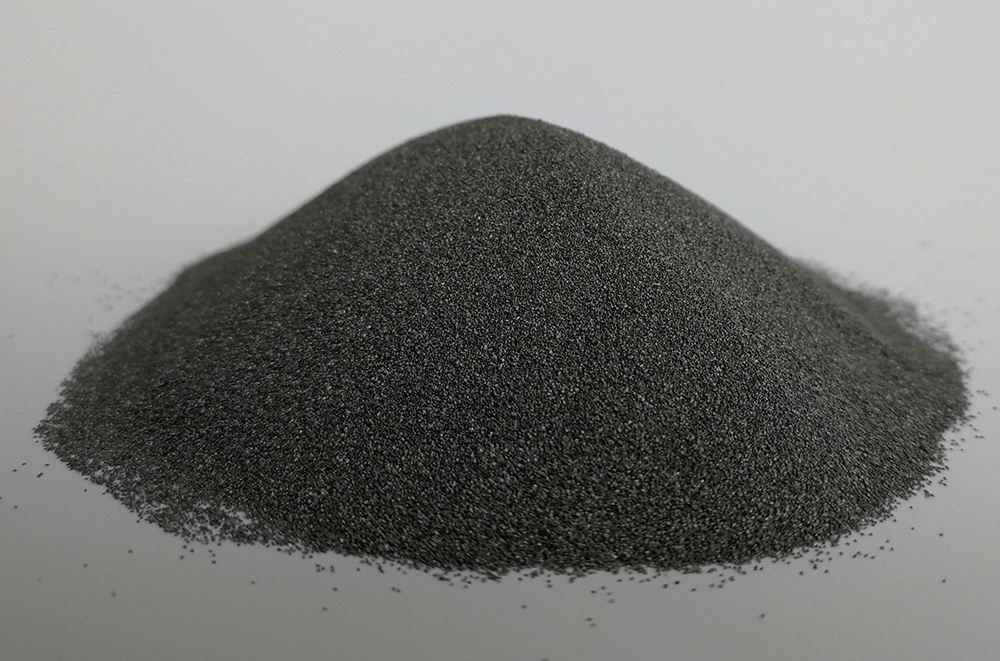

Tungsten carbide powder is a critical material used in various industries, known for its exceptional hardness and resistance to wear. As demand increases, the role of manufacturers becomes vital in ensuring a steady supply of high-quality powders. The leading tungsten carbide powder manufacturers are characterized by their stringent quality assurance processes, advanced production techniques, and the ability to cater to diverse market needs.

Major players in this field, such as Buffalo Tungsten and Global Tungsten & Powders, have established themselves by providing a range of products that meet rigorous industry standards. These manufacturers utilize processes that enhance particle size distribution and purity levels, making their offerings indispensable for applications in aerospace, construction, and metal cutting. In an era where precision and durability are paramount, understanding the capabilities and offerings of these manufacturers can greatly benefit industries reliant on tungsten carbide.

For anyone looking to optimize their supply chains or enhance product quality, exploring the landscape of tungsten carbide powder manufacturers is essential. By understanding the key attributes of these companies, industry stakeholders can make informed decisions that align with their operational goals.

The Manufacturing Process of Tungsten Carbide Powder

The manufacturing of tungsten carbide powder involves specific raw materials, distinct production techniques, and stringent quality control measures. The process is crucial for ensuring the performance and integrity of the final carbide products used in various applications.

Raw Materials Used in the Production of Tungsten Carbide Powder

Tungsten carbide powder primarily consists of tungsten and carbon. Tungsten is typically sourced from tungsten ore, which is processed to create ammonium paratungstate (APT). This material is essential for producing high-purity tungsten compounds.

The carbon source is usually in the form of graphite. In some cases, other additives may be included to enhance specific properties of the final product. The quality of these raw materials directly influences the attributes of the tungsten carbide powder.

Description of the Manufacturing Techniques Employed

The production of tungsten carbide powder generally employs powder metallurgy techniques. Initially, tungsten powder is mixed with carbon in a controlled environment. This mixture is then subjected to high temperatures in a furnace, resulting in the formation of tungsten carbide particles.

The process often involves various steps such as:

- Mixing: Combining tungsten and carbon in precise ratios.

- Sintering: Applying heat under pressure to consolidate the powder.

- Milling: Reducing particle size for enhanced uniformity.

These methods ensure the carbide has the desired density and hardness, making it suitable for diverse industrial applications.

Quality Control Measures and Standards

Quality control in tungsten carbide powder manufacturing is critical. Manufacturers implement rigorous testing protocols throughout the production process. Key measures include:

- Ingredient Verification: Ensuring raw material quality meets industry standards.

- Particle Size Analysis: Using techniques like laser diffraction to measure size distribution.

- Mechanical Testing: Assessing hardness and durability through standardized tests.

Adhering to international standards such as ISO ensures that the final product meets performance criteria critical for end users in cutting tools, mining, and other applications requiring high wear resistance.

Key Players in the Tungsten Carbide Powder Industry

The tungsten carbide powder industry is characterized by several prominent manufacturers known for their production capabilities and innovations. This section details the leading companies, their market share, and advancements in technology that are shaping the industry.

Overview of Leading Manufacturers Globally

Key players in the tungsten carbide powder industry include Kennametal, Tungsten Corp, and H.C. Starck, among others. Kennametal is recognized for its extensive range of tungsten carbide products, serving various sectors like aerospace and mining.

Tungsten Corp specializes in high-quality tungsten materials, focusing on sustainable practices. H.C. Starck is known for its innovative powder production technologies, catering to both industrial and consumer markets.

These companies maintain a competitive edge through robust supply chains and strategic partnerships, ensuring a reliable product flow in the marketplace.

Comparison of Their Production Capacities and Market Shares

Production capacity is a significant factor influencing market dynamics. For instance, Kennametal’s manufacturing plants have a reported capacity exceeding 30,000 tons annually. This positions them as a major producer in the industry.

H.C. Starck follows closely with an estimated production of around 25,000 tons per year. Tungsten Corp has also expanded its capacity, aiming for a 15,000 ton annual output.

Market share varies widely, but Kennametal leads with approximately 35% of the global market, while H.C. Starck and Tungsten Corp hold shares of roughly 25% and 20%, respectively. These figures illustrate the competitive landscape that each manufacturer navigates.

Innovations and Technological Advancements by Key Players

Innovation drives growth and efficiency in the tungsten carbide market. Kennametal invests significantly in R&D to develop superior wear-resistant materials. Their recent advancements include sintering techniques that enhance the durability of tungsten carbide powder.

H.C. Starck has patented processes for producing finer powders, which cater to high-performance applications in electronics and energy sectors.

Tungsten Corp is also focusing on environmentally friendly production methods, reducing waste and energy consumption using cutting-edge technology. This trend towards sustainable practices is becoming essential for manufacturers looking to maintain relevance in a competitive market.

Market Trends and Future Outlook

The tungsten carbide powder market is witnessing significant shifts driven by demand from various sectors and the exploration of new applications. As manufacturers adapt to the evolving landscape, they face challenges that require strategic solutions.

Current Demand for Tungsten Carbide Powder Across Various Sectors

Demand for tungsten carbide powder is largely propelled by industries such as construction, mining, and transportation. In construction, the need for durable and wear-resistant materials is critical for tools and machinery. Mining operations rely on tungsten carbide for its hardness and ability to withstand harsh conditions, making it essential for drilling and cutting tools.

According to recent estimates, the global tungsten carbide powder market was valued at approximately USD 16.88 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.7% from 2024 to 2030. This growth is further supported by the rising defense expenditure as advanced materials become crucial for modern military applications.

Emerging Applications and Potential Growth Areas

Emerging applications are expanding the scope for tungsten carbide powder. Industries are increasingly utilizing this material for producing wear-resistant parts, cutting tools, and abrasive products.

Innovations in manufacturing processes, such as additive manufacturing, are driving new uses in aerospace and automotive industries. Additionally, the growing emphasis on sustainability has led to a push for recyclable materials, providing opportunities for tungsten carbide powder in eco-friendly applications.

The anticipated CAGR of 5% during the forecast period of 2024 to 2029 indicates a robust trajectory for market growth, with potential in untapped sectors like electronics and medical devices as demand for hard materials continues to rise.

Challenges Faced by Manufacturers and Strategies to Overcome Them

Manufacturers of tungsten carbide powder confront several challenges, including fluctuations in raw material prices and intense competition. The cost of tungsten, derived mainly from mining, can vary significantly, affecting profit margins.

To navigate these challenges, companies are investing in research and development to enhance production efficiency and reduce costs. Implementing advanced technologies such as automation can streamline operations, optimizing resource use while maintaining quality.

Moreover, building long-term relationships with suppliers can mitigate the impact of price volatility. By focusing on innovation and cost control, manufacturers can capitalize on market opportunities while maintaining competitive positioning.

Conclusion

Tungsten carbide powder manufacturers play a vital role in various industries. They supply essential materials used in cutting tools, mining, and other high-performance applications.

Key manufacturers in the field include:

- Global Tungsten & Powders: Known for producing high-quality tungsten powders since the 1940s. Their expertise ensures consistent purity and performance.

- Buffalo Tungsten: Offers a range of high purity tungsten and tungsten carbide powders to global markets.

- Kennametal: Provides tungsten metal powders blended with other materials to create specialized products.

- General Carbide: Focuses on tungsten carbide, utilizing a powder metallurgy process to produce durable industrial components.

Choosing the right manufacturer involves considering factors such as:

- Purity: High purity levels enhance the performance of tungsten carbide applications.

- Consistency: Uniform particle size distribution is crucial for manufacturing reliability.

- Specialization: Some manufacturers offer custom powders tailored to specific needs.

Collaboration with reputable manufacturers ensures access to quality tungstens, leading to enhanced product performance across various applications. It remains essential for industries to evaluate their options carefully.