Molybdenum Powder

Molybdenum Disulfide Powder

Molybdenum Trioxide Powder

Molybdenum Boat

Molybdenum Electrode

Molybdenum Mandrel

Molybdenum Heating Elements

Molybdenum Heating Shields

Molybdenum Fasteners

Molybdenum Sputtering Target

TZM Alloy

Molybdenum Tungsten Alloy

-

Molybdenum Plate

Molybdenum Plate -

Molybdenum Rhenium Alloy

Molybdenum Rhenium Alloy -

Molybdenum & TZM Nozzle

Molybdenum & TZM Nozzle -

Molybdenum Copper Alloy

Molybdenum Copper Alloy -

Molybdenum Disc & Square

Molybdenum Disc & Square -

Molybdenum Carbide Powder

Molybdenum Carbide Powder -

Molybdenum Crucible

Molybdenum Crucible -

Molybdenum Sheet

Molybdenum Sheet -

Molybdenum Tube

Molybdenum Tube -

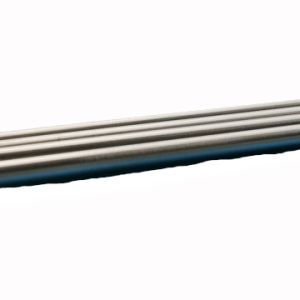

Molybdenum Rod

Molybdenum Rod -

Molybdenum Bar

Molybdenum Bar -

Mo-La Alloy

Mo-La Alloy -

Molybdenum Tungsten Alloy

Molybdenum Tungsten Alloy -

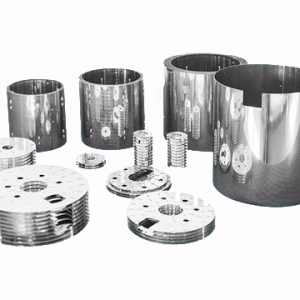

TZM Alloy

TZM Alloy -

Molybdenum Sputtering Target

Molybdenum Sputtering Target -

Molybdenum Fasteners

Molybdenum Fasteners -

Molybdenum Heating Shields

Molybdenum Heating Shields -

Molybdenum Heating Elements

Molybdenum Heating Elements -

Molybdenum Mandrel

Molybdenum Mandrel -

Molybdenum Electrode

Molybdenum Electrode -

Molybdenum Boat

Molybdenum Boat -

Molybdenum Trioxide Powder

Molybdenum Trioxide Powder -

Molybdenum Disulfide Powder

Molybdenum Disulfide Powder -

Molybdenum Powder

Molybdenum Powder

Molybdenum

Molybdenum is a refractory metal with unique mechanical and chemical properties. It has a high melting point (2620°C) and boiling point (5,560°C). This high strength, tough, hard metal has excellent thermal conductivity, low heat resistance, and a low degree of thermal expansion. Molybdenum’s unique properties give rise to processes and applications in electronics, aerospace, nuclear, and metalworking industries, which would not be possible with many more common metals and alloys.

ARS can provide molybdenum metal powders and molybdenum semi-finished and finished products with high quality and competitive prices. Below are some of our standard molybdenum products. If you require some custom products, please contact us.

Physical Properties of Molybdenum

| Molybdenum Physical Properties | ||

|---|---|---|

| Density | lb/in3 | 0.369 |

| gm/cm3 | 10.3 | |

| Melting Point | °F | 4760 |

| °C | 2625 | |

| Thermal Conductivity | Cal/cm2/cm°C/sec | 0.35 |

| Specific Heat | Cal/gm/°C | 0.061 |

| Coefficient of Linear Thermal Expansion | micro-in/°F x 10-6 | 4.9 |

| micro-in/°C x 10-6 | 2.7 | |

| Electrical Resistivity | micro-ohm-cm | 5.17 |

| Recrystallization Temp. | °C | 1100 |

Mechanical Properties of Molybdenum

| Molybdenum Mechanical Properties | ||

|---|---|---|

| Tensile Strength | KSI (Mpa)-RT | 150 (1035) |

| KSI (Mpa)-500°C | 75 (515) | |

| KSI (Mpa)-1000°C | 25 (175) | |

| Elongation | % in 1.0″. | — |

| Hardness | DPH | 230 |

| Modulus of Elasticity | KSI | 45000 |

| Gpa | 310 | |

| Molybdenum Chemistry | |

|---|---|

| Minimum % 99.95 |

Applications of Molybdenum

1. High-temperature applications including furnace parts, lighting components, and electrical contacts.

2. Commonly added to high strength steel alloys.

3. Used in the production of molten zinc

Applications of Molybdenum Rod, Sheet, Plate

1. In the missile industry, molybdenum is used for: nose cones, high-temperature structural parts, nozzles, leading edges of control surfaces, support vanes, re-entry cones, and heat radiation shields.

2. In electronics, molybdenum is used for: cathodes, magnetron end hats, x-ray tube components, filaments, and glass-to-metal seals.3. In high-temperature applications, molybdenum is used for: furnace windings, structural furnace members, and containers for components exposed to high temperatures.

Applications of Molybdenum Precision Cut Wire

Molybdenum wire is widely used to construct power tube grids and support structures requiring high-temperature strength, low vapor pressure, and low thermal expansion. Molybdenum wire (and rod) is also used in high-temperature vacuum and hydrogen atmosphere furnaces to form resistance heating elements. Molybdenum wire may also be used as a heat sink and support for tungsten lamp filaments in lighting applications.