Tungsten oxide powder is an important material known for its unique properties and versatile applications. It serves as a semiconducting material with outstanding electrochromic properties, making it valuable in various fields including electronics and optics. Researchers and industrial professionals alike recognize its potential for use in products such as smart windows, solar cells, and catalysts.

This compound can be synthesized through methods like chemical vapor deposition and sol-gel processes, allowing for customization of its characteristics. By understanding the properties and production methods of tungsten oxide powder, individuals can unlock its potential for innovative applications.

As interest in advanced materials grows, tungsten oxide powder continues to be a focal point of research and development, appealing to industries that require high-performance materials. Exploring its benefits, uses, and synthesis methods reveals why tungsten oxide powder holds significant value in modern science and technology.

Properties of Tungsten Oxide Powder

Tungsten oxide powder exhibits a range of important properties that contribute to its versatility and effectiveness in various applications. This section explores its chemical composition, physical characteristics, and unique qualities.

Chemical Composition and Structure

Tungsten oxide (WO₃) is primarily composed of tungsten and oxygen. The structure can vary, with different phases such as monoclinic, hexagonal, and cubic. The monoclinic form is the most stable at room temperature.

The chemical formula indicates that each tungsten atom is surrounded by six oxygen atoms in a distorted octahedral geometry. This arrangement leads to unique electronic properties, making tungsten oxide useful in catalysis and electrochemical applications.

Additionally, the reduction of tungsten oxide to tungsten metal often involves processes where hydrogen reduces WO₃ at high temperatures. This chemical transformation is crucial for producing high-purity tungsten powder for various industries.

Physical Properties, Including Color and Particle Size

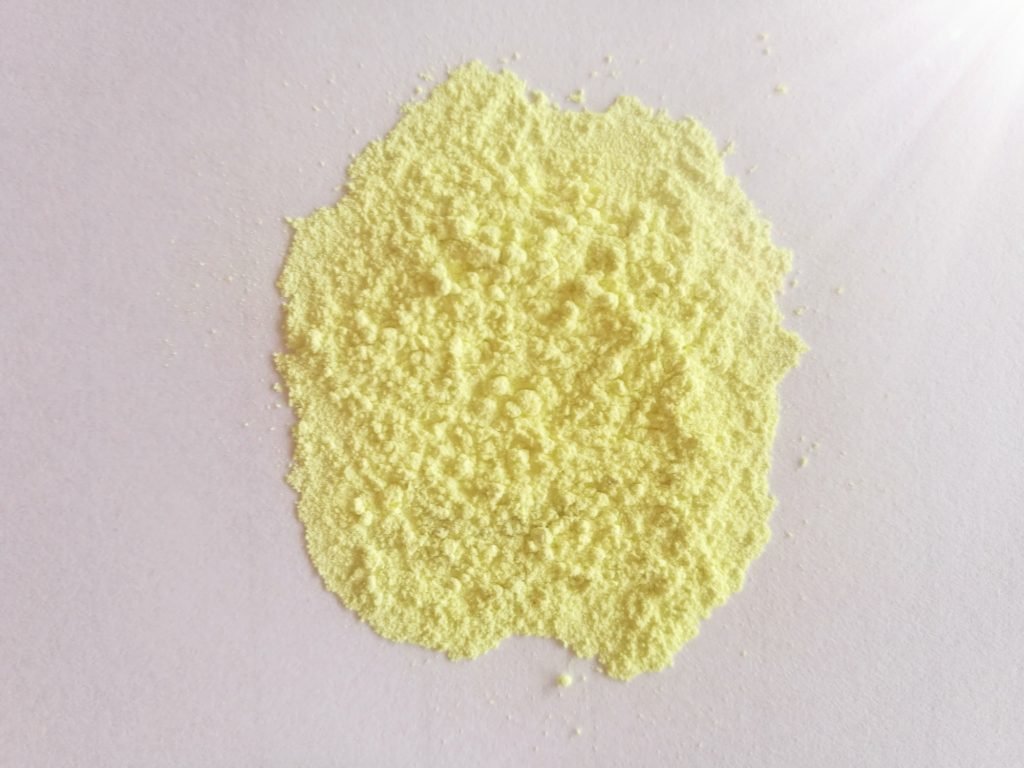

Tungsten oxide powder appears as a yellow to blue solid, depending on its oxidation state and preparation method. For example, the trigonal blue form of WO₃ has specific optical properties that make it effective in applications like smart windows.

The particle size of tungsten oxide can range from nanometers to micrometers, with average particle sizes from 0.1 to 100 µm commonly produced. Smaller particles can enhance reactivity and surface area, which is advantageous in catalytic and chemical processes.

The powder’s density typically ranges between 6.1 and 6.3 g/cm³. Its high melting point, approximately 1473 °C, further emphasizes its stability under thermal stress, making it suitable for high-temperature applications.

Unique Characteristics That Make It Valuable for Applications

Tungsten oxide powder possesses unique attributes that enhances its value in several fields. Its semiconductor properties allow it to be utilized in electronic devices and sensors effectively.

Moreover, its photocatalytic capabilities enable it to facilitate chemical reactions under light exposure, which benefits environmental applications like wastewater treatment.

In addition, tungsten oxide exhibits exceptional resistance to corrosion and chemical attack, making it suitable for various industries, including aerospace and energy. Other applications include its use as a coating material and in the production of tungsten metal for high-performance alloys.

These distinct properties contribute to the ongoing research and development efforts in harnessing tungsten oxide’s potential.

Applications of Tungsten Oxide Powder

Tungsten oxide powder has diverse applications in various industries, primarily due to its unique properties. Its utility spans electronics, catalysis, and colorant production.

Use in Electronics and Semiconductors

Tungsten oxide powder plays a critical role in electronics. It is employed in the production of thin films that exhibit electrochromic properties, which allow materials to change color or opacity when subjected to electric current. This feature is particularly useful for smart windows and display technologies.

In addition, tungsten oxide serves as a dielectric material in capacitors. Its high dielectric constant enhances capacitance, leading to improved performance in electronic devices. The powder is also a key component in varistors, which protect against voltage spikes, ensuring system reliability.

Role in Catalysts and Chemical Processes

Tungsten oxide is significant in catalysis, especially in reactions involving oxidation and reduction. As a catalyst, it promotes reactions that convert harmful emissions into less harmful substances. Its catalytic properties are harnessed in environmental applications, particularly for diesel engine emissions.

Moreover, tungsten oxide is utilized in photo-catalytic processes. When exposed to light, it can break down organic pollutants in wastewater, demonstrating its potential for sustainable chemical processes. This capability makes it valuable in water purification systems.

Applications in the Production of Pigments and Coatings

In the field of pigments, tungsten oxide powder is employed to create vibrant colors. It is used in ceramic glazes and glass coatings, where it imparts a rich hue while enhancing durability. The stability of tungsten oxide at high temperatures makes it suitable for applications that require thermal resistance.

Additionally, tungsten oxide coatings are applied to enhance surfaces, providing properties such as corrosion resistance and improved wear. They are used in various industries, including automotive and aerospace, to protect components from harsh environments while maintaining aesthetic appeal.

Production and Synthesis Methods

Tungsten oxide powder production involves various techniques, each with specific advantages and challenges. Understanding these methods is essential for ensuring high purity and optimizing the material’s properties.

Overview of Common Production Techniques

Several techniques are employed in the production of tungsten oxide powder. Key methods include:

- Mechanochemical Synthesis: This method utilizes mechanical energy to induce chemical reactions, often yielding fine powders.

- Hydrothermal Synthesis: Involves using water at high temperatures and pressures to promote chemical reactions, resulting in controlled crystal growth.

- Vapor-Phase Synthesis: This technique allows for the deposition of tungsten oxide from gas-phase precursors, producing highly pure and uniform films.

- Solid-State Reaction: A traditional method where tungsten oxide is produced by high-temperature reactions between solid reactants.

Each method has unique attributes that affect the particle size, morphology, and purity of the final product.

Discussion of Purity and Quality Control Measures

Ensuring the purity of tungsten oxide powder is crucial for its performance in applications. Quality control measures include:

- Characterization Techniques: Methods such as X-ray diffraction (XRD) and scanning electron microscopy (SEM) are used to evaluate phase composition and particle morphology.

- Chemical Analysis: Techniques like inductively coupled plasma mass spectrometry (ICP-MS) can detect trace impurities that may compromise the material.

Maintaining strict quality control throughout the production process can prevent contamination and ensure consistent performance in end-use applications.

Innovations in Synthesis Methods and Their Implications

Recent advancements in synthesis methods have significant implications for tungsten oxide powder production. Innovations include:

- Nano-Scale Synthesis: Techniques are evolving to produce tungsten oxide at the nanoscale, enhancing reactivity and specific surface area.

- Green Chemistry Approaches: Sustainable methods aim to minimize waste and reduce hazardous materials in synthesis.

- Tailored Morphology: New methods allow for the tailoring of particle shapes and sizes, which can optimize performance in applications such as catalysis and energy storage.

These innovations are shaping the future of tungsten oxide materials by improving function and efficiency in various industrial applications.

Conclusion

Tungsten oxide powder plays a significant role in various fields due to its unique properties. Its applications range from electronics to catalysts, and advancements in its synthesis techniques continue to enhance its utility. This section explores the importance of tungsten oxide powder, future trends, and its impact on technology and industry.

Recap of the Importance of Tungsten Oxide Powder

Tungsten oxide powder is valued for its unique characteristics, such as high thermal stability and a wide band gap, making it essential in semiconductor technology. It is employed in applications like gas sensors, photochemical processes, and smart windows due to its electrochromic properties.

In addition, its n-type semiconductor behavior enhances efficiency in optoelectronic devices. The material’s excellent catalytic properties also contribute significantly to energy-related applications, such as hydrogen production and environmental remediation strategies.

Future Trends and Potential Developments in Its Applications

Emerging trends in tungsten oxide powder research focus on enhancing its functionality and adaptability. Innovations in synthesis methods, including hydrothermal and microwave-assisted techniques, are expected to yield more efficient and cost-effective production of tungsten oxide nanostructures.

Additionally, the integration of tungsten oxide in nano- and composite materials opens new avenues for advanced applications. For instance, its combination with other materials could lead to breakthroughs in energy storage devices and improved photocatalytic performance.

Furthermore, ongoing studies into its use in flexible electronics and photovoltaic cells hold promise for creating more sustainable technologies.

Final Thoughts on the Role of Tungsten Oxide Powder in Advancing Technology and Industry

Tungsten oxide powder continues to be integral in the progress of various technological sectors. Its exceptional properties offer potential solutions to modern challenges in energy efficiency and environmental sustainability.

As industries move towards greener technologies, tungsten oxide’s role is likely to expand, driving innovations that could significantly impact manufacturing processes and product development.

The commitment to research and development within this field will ensure that tungsten oxide powder remains a key material driving advancements in technology and industry for years to come.