Tungsten powder additive manufacturing is revolutionizing the fabrication of complex components in various industries, particularly those requiring materials that can withstand extreme environments. This innovative process enables the production of intricate tungsten parts while addressing challenges like high melting points and brittleness. The versatility of additive manufacturing opens new possibilities for using tungsten in high-performance applications.

Many industries are discovering the advantages of using tungsten due to its exceptional properties, such as high density and thermal stability. With advancements in techniques like laser powder bed fusion, manufacturers are overcoming the traditional limitations associated with tungsten processing. Companies are now able to produce parts that were previously deemed too complex or costly.

As demand for durable materials continues to grow, the potential of tungsten powder additive manufacturing becomes clearer. Readers can explore how this technology not only enhances design flexibility but also increases efficiency in production settings. Understanding these factors will provide valuable insights into the future of manufacturing in critical applications.

Properties Of Tungsten Powder

Tungsten powder possesses unique characteristics that make it particularly suited for additive manufacturing. Understanding its physical and chemical properties, advantages in manufacturing, and comparisons with other metal powders is essential for engineers and manufacturers.

Physical And Chemical Characteristics

Tungsten powder exhibits several notable physical and chemical characteristics. It is a dense, hard, and brittle material with a remarkable melting point of approximately 3,422 °C (6,192 °F). This high melting point contributes to its stability in high-temperature applications. Tungsten is resistant to oxidation and corrosion at elevated temperatures, making it suitable for use in harsh environments.

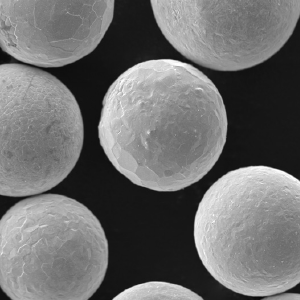

The powder form of tungsten allows for fine particle sizes, which enhance its flowability and compaction during additive manufacturing processes. Additionally, tungsten’s ductile-to-brittle transition temperature poses challenges, limiting its processing at lower temperatures. Modifications in processing techniques are often required to address these challenges and ensure successful fabrication of components.

Advantages Of Using Tungsten Powder In Manufacturing

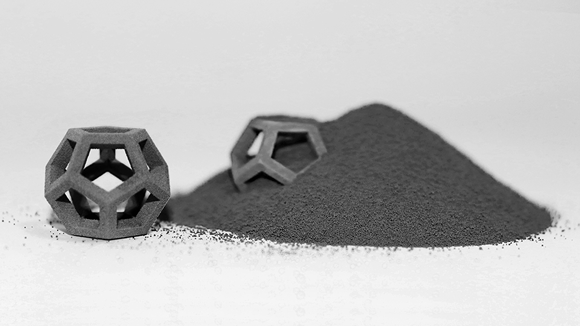

The use of tungsten powder in manufacturing offers numerous advantages. Its exceptional mechanical properties, such as high tensile strength and hardness, make it ideal for applications requiring durability. The ability to create complex geometries through additive manufacturing enables the production of intricate parts that traditional methods cannot achieve.

Tungsten parts fabricated using selective laser melting (SLM) can exhibit excellent density and strength, leading to enhanced performance in various industries, including aerospace and automotive. Furthermore, tungsten’s stability under extreme conditions makes it a preferred choice for high-temperature applications, such as in rockets and nuclear reactors.

Additionally, tungsten’s ability to be repurposed and recycled contributes to sustainable practices in manufacturing. These factors make tungsten powder a valuable material in the additive manufacturing landscape.

Comparison With Other Metal Powders Used In Additive Manufacturing

Compared to other metal powders, tungsten powder has distinct advantages and challenges. While metals like aluminum and titanium are more ductile and easier to process, tungsten’s unique properties allow for high-performance applications. For example, titanium is known for being lightweight and corrosion-resistant, whereas tungsten’s density and strength are unmatched in demanding environments.

Other metal powders may offer better flowability, which can enhance the printing process. However, tungsten’s high melting point and ability to withstand extreme temperatures make it indispensable for specific applications.

In summary, while tungsten powder may present challenges such as cracking and low densification during processing, its advantages for high-performance applications are significant. This comparison highlights the importance of selecting the appropriate powder based on the specific requirements of the project.

Additive Manufacturing Techniques For Tungsten Powder

The additive manufacturing of tungsten powder involves various techniques, each with its nuances. Understanding these methods is crucial for optimizing the properties and performance of tungsten-based components.

Overview Of Different Additive Manufacturing Methods

Several additive manufacturing techniques are utilized for tungsten powder, including Laser Powder Bed Fusion (L-PBF), Binder Jetting, and Directed Energy Deposition (DED).

- Laser Powder Bed Fusion (L-PBF): This technique employs a focused laser to selectively melt tungsten powder layers, building parts layer-by-layer. It allows for the creation of complex geometries but can lead to issues such as microcracks due to high residual stress.

- Binder Jetting: In this method, a liquid binder is used to bond tungsten powder particles, forming a green body that is then sintered. This technique is advantageous for producing large-scale components with less thermal stress compared to L-PBF.

- Directed Energy Deposition (DED): This process involves melting tungsten powder as it is deposited onto a substrate using an energy source like a laser or electron beam. It is suitable for repairing components and producing near-net-shape parts.

Challenges Associated With Tungsten Powder Processing

The processing of tungsten powder through additive manufacturing presents several challenges. Tungsten’s high melting point complicates the melting process.

Key Challenges Include:

- High Thermal Conductivity: Tungsten dissipates heat quickly, making it difficult to achieve adequate melting.

- Brittleness: At room temperature, tungsten is notably brittle, which can lead to crack formation during processing.

- Low Laser Absorptivity: Tungsten’s low absorptivity to laser radiation results in inefficient energy transfer during techniques like L-PBF, requiring higher energy inputs.

These factors necessitate careful control of processing parameters to mitigate defects and ensure part integrity.

Innovations And Advancements In Tungsten Additive Manufacturing

Recent advancements focus on improving the properties of tungsten components in additive manufacturing. Innovative techniques aim to enhance processing efficiency and part quality.

- Nanoscale Surface Modifications: Introducing nanoscale grooves to tungsten powder surfaces can increase absorptivity by up to 70%, enhancing energy transfer during laser processing.

- Hybrid Approaches: Combining additive and subtractive processes can refine dimensional accuracy and surface finish, optimizing performance in demanding applications.

- New Alloy Formulations: Research into tungsten alloys with improved ductility and reduced brittleness is underway, potentially expanding the application range of tungsten in extreme environments.

These innovations reflect the ongoing efforts to enhance the feasibility and capabilities of tungsten powder within additive manufacturing.

Applications Of Tungsten Powder Additive Manufacturing

Tungsten powder additive manufacturing is making significant impacts across various industries. Its unique properties enable the creation of components that can withstand extreme conditions, making it suitable for specialized applications.

Aerospace And Defense Applications

In the aerospace and defense sectors, tungsten parts are valued for their high density and radiation shielding properties. Components such as weights, counterbalances, and protective housings are often produced using tungsten powder additive manufacturing.

This method allows for complex geometries that can optimize aerodynamic efficiency. Additionally, the ability to create lightweight structures enhances performance while maintaining strength. Using tungsten provides resilience in extreme temperatures, which is essential for applications involving high-speed aircraft and spacecraft.

Medical And Dental Applications

The medical and dental industries benefit from tungsten’s biocompatibility and durability. Additive manufacturing facilitates the production of intricate surgical tools, implants, and prosthetics. These components can be tailored to meet specific patient needs, improving outcomes.

For example, tungsten is used in radiation therapy equipment. Its high atomic number allows it to effectively block unwanted radiation, safeguarding surrounding tissues. Customizable tools also reduce recovery times due to their precise fit and function, illustrating the utility of tungsten in healthcare.

Energy Sector Applications

In the energy sector, tungsten powder additive manufacturing is increasingly utilized for components in nuclear reactors and advanced thermal systems. Tungsten’s high melting point and structural integrity make it ideal for high-temperature applications.

Components such as nozzles, heat exchangers, and radiation shields leverage tungsten’s ability to withstand extreme conditions. This enhances the efficiency and safety of energy systems, contributing to more reliable power generation. The versatility of tungsten facilitates innovations in both conventional and renewable energy technologies.

Emerging Applications And Future Potential

Emerging applications for tungsten powder additive manufacturing are expanding rapidly. Industries exploring the use of tungsten include automotive, electronics, and advanced military technologies. Its potential in lightweight armor materials and heat-resistant components is garnering significant interest.

With ongoing research focused on overcoming challenges like ductility and cracking, the future looks promising. As techniques improve, tungsten’s role in innovative manufacturing processes may lead to custom solutions in varied fields. The unique properties of tungsten position it well to meet evolving industry demands.

Conclusion

The advancements in tungsten powder additive manufacturing demonstrate its significance in producing high-performance components. The benefits of tungsten’s properties and the ongoing developments in the field indicate a promising future. The following subsections detail the importance of tungsten powder, anticipated trends, and the broader impact on industries.

Recap Of The Significance Of Tungsten Powder In Additive Manufacturing

Tungsten powder plays a critical role in additive manufacturing due to its unique properties, including high melting point and exceptional strength. These characteristics enable the production of components that withstand extreme conditions, making tungsten essential for aerospace and nuclear applications.

The ability to use tungsten powders in laser-powder bed fusion (L-PBF) technologies enhances the capability to create intricate geometries. This method allows for near-net-shape production, which minimizes material waste and reduces costs. Its application is notably valuable in creating parts that require high-density and structural integrity.

Future Trends And Developments In The Field

The landscape of tungsten powder additive manufacturing is set to evolve significantly. Ongoing research focuses on improving the flowability and melting efficiency of tungsten powders to enhance the printing process. Innovations may lead to better consolidation and reduced cracking during fabrication.

Furthermore, machine learning and artificial intelligence technologies are being integrated into additive processes. These advancements will likely optimize parameters for printing tungsten components, enhancing quality and reliability. As industries seek materials capable of high-performance at elevated temperatures, tungsten’s applications in additive manufacturing will expand.

Final Thoughts On The Impact Of Tungsten Powder Additive Manufacturing On Industry Advancements

The implications of tungsten powder additive manufacturing extend beyond compliance with current industrial demands. This technology fosters the production of lighter, stronger components, which is vital in sectors such as aerospace and defense.

Moreover, the ability to create customized parts quickly improves supply chain efficiency. As companies adopt these innovative manufacturing techniques, tungsten powder is positioned to drive future breakthroughs in material science and engineering. Furthermore, the widespread integration of tungsten in additive manufacturing can lead to an overall reduction in production costs while maintaining high quality.