Tungsten powder is often sought after for its unique properties and applications in various industries. The weight of tungsten powder typically ranges from 19.3 grams per cubic centimeter (g/cm³), making it one of the heaviest metals available. This impressive density contributes to its use in applications such as ballast weights in motorsports, counterweights in various tools, and even in aerospace engineering.

In addition to its weight, the purity of tungsten powder can significantly impact its applications and performance. High purity grades, often exceeding 99.95% tungsten, are essential for specialized uses, including in the medical and electronics fields. Understanding the weight and purity factors is vital for industries relying on tungsten powder to ensure they select the appropriate material for their specific needs.

By exploring tungsten powder’s weight and its implications, readers can gain insights into its suitability for different applications, enhancing their knowledge of this crucial material. This information will be valuable for anyone involved in procurement, manufacturing, or research related to tungsten.

Properties Of Tungsten Powder

Tungsten powder possesses distinct properties that contribute to its effectiveness in various industrial applications. Understanding its physical characteristics, density implications, and how it compares to other metal powders provides valuable insight.

Physical Characteristics Of Tungsten

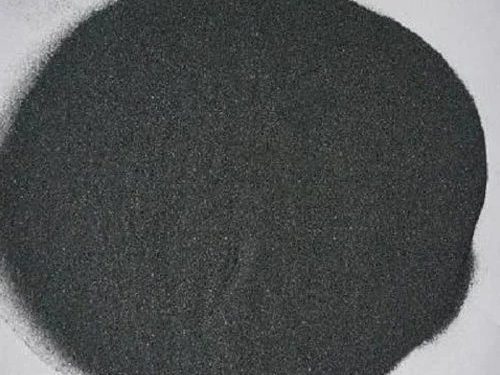

Tungsten powder is characterized by its silvery appearance and remarkable hardness. It has a high melting point of 3,422 °C (6,192 °F), enabling it to withstand extreme temperatures without degrading. The powder is typically produced through mechanical milling or chemical reduction, resulting in fine particles that may range in size from a few microns to several hundred microns.

The particles exhibit a high level of purity, with tungsten content often exceeding 99%. Impurities can include trace elements such as oxygen and carbon. These purity levels are crucial in applications requiring stringent material specifications, like aerospace or nuclear industries.

Density And Its Implications For Tungsten Powder Weight

Tungsten powder has a high density, generally around 19.3 grams per cubic centimeter. This density makes it one of the heaviest elements used in powder metallurgy. The high density impacts how tungsten powder is handled, packed, and processed.

When formulating components, the weight of tungsten can lead to advantages in applications where weight is a critical factor, such as in counterweights or radiation shielding. The ability to achieve high-density sintered parts is essential, resulting in materials that maintain structural integrity under stress.

Comparison With Other Metal Powders

When compared to other metal powders, tungsten stands out for its exceptional hardness and thermal resistance. For example, iron and aluminum powders, while useful, do not match tungsten’s high melting point and density. Tungsten powder exhibits superior wear resistance, making it ideal for cutting tools and components subjected to high abrasion.

In powder metallurgy, tungsten often commands a higher cost due to its availability and processing requirements. Therefore, it is essential to consider both performance capabilities and economic factors when selecting metal powders for specific applications.

Applications Of Tungsten Powder

Tungsten powder is widely used across various industries due to its unique properties such as high density, excellent thermal conductivity, and resistance to high temperatures. Its applications are crucial in manufacturing, electronics, aerospace, and high-performance materials.

Use In Manufacturing And Industrial Processes

Tungsten powder is essential in manufacturing processes, particularly in producing hard metals and alloys. It is commonly utilized in the production of cutting tools, such as drill bits and milling inserts. These tools benefit from tungsten’s hardness and durability, enabling them to withstand intense wear and tear.

Additionally, tungsten powder is used in sintering processes, where it is compacted and heated to form solid components. This technique is vital in producing parts for various applications, including mining and construction equipment. The resulting products maintain precision and strength, making tungsten an excellent choice for industrial applications.

Role In Electronics And Aerospace Industries

In the electronics industry, tungsten powder is used to create contacts and heat sinks due to its high melting point and thermal stability. Its properties allow for efficient heat dissipation, which is crucial in electronic components. Tungsten’s ability to operate under extreme conditions makes it ideal for high-performance electronic applications.

In aerospace, tungsten powder is employed in turbine blades and rocket nozzles. These components require materials that can withstand high temperatures and stress, making tungsten a favored choice. Its weight-to-strength ratio contributes to the performance and efficiency of aircraft and spacecraft, ensuring safety and reliability.

Importance In The Production Of High-Performance Materials

Tungsten powder plays a significant role in generating high-performance materials, including composites and specialized alloys. It is blended with other metals to improve hardness, strength, and wear resistance. These high-performance materials are often used in demanding environments, such as military applications and advanced manufacturing.

Furthermore, tungsten powder’s ability to serve as a metal matrix in composite materials enhances thermal and electrical conductivity. This characteristic is beneficial in applications that require both durability and lightweight properties, such as automotive parts and advanced machinery. The versatility of tungsten makes it indispensable in producing innovative and efficient materials.

Factors Influencing Tungsten Powder Weight

Several factors significantly affect the weight of tungsten powder, impacting its applications and processing. These include the particle size and distribution, purity level, and environmental conditions during production and storage.

Particle Size And Distribution

The particle size and distribution of tungsten powder play a crucial role in determining its weight. Smaller particles tend to have a larger surface area, which can lead to variations in bulk density. This is because finer powders may pack more densely, resulting in a heavier weight per unit volume.

Uniform particle size contributes to consistent weight characteristics, essential for many applications. Variability in particle size can affect how the powder flows during manufacturing, ultimately influencing the weight of produced components.

Purity And Its Effect On Tungsten Powder Weight

Purity levels directly influence the weight of tungsten powder. Higher purity tungsten, generally containing 99% to 99.995% tungsten, ensures that the weight calculations reflect the metal’s true density. Impurities, such as tungsten trioxide (WO3), can alter the weight by adding lighter elements to the composition.

Consequently, manufacturers must account for purity when measuring and specifying tungsten powder weight. A reduction in impurities leads to a more precise weight and enhances the powder’s overall performance in applications requiring high efficiency.

Environmental Factors During Production And Storage

Environmental conditions during the production and storage of tungsten powder significantly impact its weight. Factors like humidity, temperature, and air composition can cause oxidation or agglomeration of the particles, altering their weight.

High humidity levels may lead to moisture absorption, affecting the powder’s density and weight. Proper storage conditions are critical to maintaining the desired properties of tungsten powder until it reaches the end user. Effective management of these factors ensures the consistency of tungsten powder weight across various production batches.

Conclusion

Tungsten powder weight is crucial in various applications, influencing performance, material choice, and product design. The following subsections highlight its significance, impact, and potential for future exploration.

Recap Of The Significance Of Tungsten Powder Weight

The weight of tungsten powder is a key factor in industries such as aerospace, electronics, and energy. Its high density and strength-to-weight ratio make it ideal for components that must endure extreme conditions.

For instance, in aerospace engineering, reduced weight is vital for fuel efficiency. Tungsten’s density allows for smaller, lighter parts without compromising strength. This aspect has led to innovations in design and manufacturing processes, emphasizing the importance of tungsten powder’s weight.

Final Thoughts On Its Impact On Industry And Technology

Tungsten powder’s weight plays a significant role in modern technology. In the field of electronics, for example, components made from tungsten materials often enhance device longevity and thermal stability.

Applications in radiation shielding, due to tungsten’s dense nature, protect sensitive equipment and personnel. This functionality supports advancements in medical and environmental technologies, showcasing how tungsten powder weight shapes innovation across sectors.

Encouragement For Further Exploration Of Tungsten Applications

Exploring tungsten applications can lead to new discoveries in material science and engineering. Researchers and industries are encouraged to investigate its potential further.

From developing next-generation batteries to improvements in high-temperature resistance, tungsten’s versatile properties offer numerous avenues for exploration. The growing demand in various sectors positions tungsten as a material worthy of deeper study and application development.