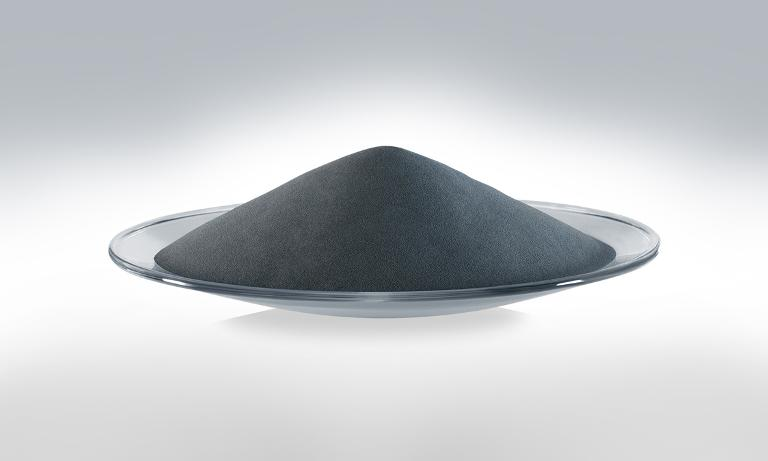

Metal powders play a crucial role in various industries, from manufacturing to advanced technologies. These powders can be produced through several methods, including direct reduction and gas atomization, making them versatile for applications in powder metallurgy, additive manufacturing, and surface coatings. Their ability to provide unique properties and reduce material waste has made them increasingly important in modern production processes.

As industries aim for greater efficiency and sustainability, metal powders offer innovative solutions that meet these goals. The versatility of metal powders extends to specialty alloys like Inconel and Hastelloy, which are used in demanding applications such as fuel cells and coatings. This broad range of applications highlights the significance of metal powders in advancing both current technologies and future innovations.

Understanding the production processes and applications of metal powders is essential for professionals in fields like manufacturing, engineering, and materials science. The ongoing development in this area promises to enhance productivity while addressing environmental concerns, making it a topic worth exploring further.

Types of Metal Powders

The classification of metal powders encompasses various materials, production methods, and their characteristics. Each type possesses unique properties that cater to specific applications in manufacturing and engineering.

Classification Based on Material

Metal powders can be categorized primarily into three groups: ferrous, non-ferrous, and alloy powders.

- Ferrous Powders:

- Derived from iron or its alloys.

- Used extensively in machinery and vehicle components due to their strength.

- Examples include iron, carbon steel, and stainless steel powders.

- Non-Ferrous Powders:

- Composed of metals other than iron.

- Typically exhibit better corrosion resistance.

- Common types include aluminum, copper, and titanium powders.

- Alloy Powders:

- Combinations of two or more metals.

- Designed to achieve specific mechanical, electrical, or thermal properties.

- Examples are bronze and brass powders, utilized in decorative and industrial applications.

Production Methods

Metal powders are produced through various techniques, each influencing the powder’s quality and characteristics:

- Atomization: Liquid metal is sprayed into a cooling atmosphere, forming fine droplets that solidify into powder. This method is highly popular for producing high-quality metal powders.

- Reduction: Involves the chemical reduction of metal oxides using gases like hydrogen or carbon. This process is commonly used for producing iron and tungsten powders.

- Mechanical Milling: Metal chunks are physically ground into powder. This method is effective for materials that are difficult to reduce chemically.

- Chemical Methods: Metals are precipitated from their salts. This method is used mainly for producing pure metal powders like nickel and cobalt.

Characteristics and Properties of Different Metal Powders

Different metal powders possess distinct characteristics influencing their applications:

- Particle Size: Smaller particles are used in applications requiring detailed precision, while larger powders may be used for structural components.

- Morphology: The shape of powder particles affects flowability and packing density. Spherical powders offer better flow compared to irregular shapes.

- Purity: High-purity powders are essential for applications in aerospace and biomedical fields, where contaminants can adversely affect performance.

- Surface Area: Increased surface area enhances sintering efficiency in powder metallurgy, which is crucial for achieving desired material properties during final processing.

Each of these characteristics directly impacts performance in applications ranging from additive manufacturing to traditional sintering processes.

Applications of Metal Powders

Metal powders play a crucial role in various industries due to their unique properties and versatility. Their applications span additive manufacturing, powder metallurgy processes, and significant uses in the automotive, aerospace, and medical sectors.

Additive Manufacturing and 3D Printing

Additive manufacturing, commonly known as 3D printing, utilizes metal powders to create complex geometries that traditional manufacturing methods cannot achieve. This technology enhances design flexibility, allowing for customized components tailored to specific needs.

Metal powders used in 3D printing can vary from pure metals to alloys. They undergo processes such as selective laser melting (SLM) and electron beam melting (EBM). These methods fuse layers of powder to build up a final product, achieving high precision and surface quality. The ability to optimize weight and performance makes metal powders indispensable in modern manufacturing.

Powder Metallurgy Processes

Powder metallurgy processes involve compacting metal powders and sintering them to produce parts with near-final shapes. The primary advantage of these processes is their ability to create complex shapes with minimal waste, a significant improvement over traditional machining.

Various methods are employed in powder metallurgy, including mechanical milling, atomization, and chemical reduction. The final properties of components depend on the powder characteristics, such as particle size, morphology, and composition. Cost-effectiveness and the capacity to produce large quantities of parts make powder metallurgy a preferred choice in many applications.

Use in Automotive, Aerospace, and Medical Industries

In the automotive and aerospace industries, metal powders are essential for producing lightweight and high-strength components. Critical applications include gears, bearings, and structural parts where durability and performance are paramount.

In the medical field, metal powders are increasingly used for implants and prosthetics. Specialized powders, such as titanium and cobalt-chromium alloys, are favored due to their biocompatibility and corrosion resistance. Customization of medical devices using powder-based methods leads to improved patient outcomes and satisfaction.

Advantages and Challenges of Using Metal Powders

Metal powders offer unique advantages in manufacturing processes while also presenting specific challenges. Understanding these factors can help in evaluating their suitability for different applications.

Benefits

One of the primary benefits of using metal powders is the ability to create complex geometries. This capability is crucial for producing intricate designs that are difficult to achieve through traditional machining methods.

Metal powders also support efficient material usage. Excess material is minimized, reducing waste in production. This contributes to lower environmental impact and lowers costs associated with scrap.

Another significant advantage is the potential for tailoring material properties. By adjusting the particle size and composition of the metal powders, manufacturers can achieve desired mechanical properties such as strength and ductility. This precision opens up opportunities for custom solutions across various industries.

Challenges

While metal powders provide numerous advantages, they also present challenges. One major issue is the cost associated with powder production. Advanced techniques, such as atomization and chemical reduction, can be expensive, limiting accessibility for some manufacturers.

The handling and storage of metal powders also require careful consideration. Powders are often flammable and can pose health risks, necessitating strict safety protocols.

Another challenge is achieving uniformity in properties across batches. Variability in powder characteristics can lead to inconsistent performance in the final products, which can be particularly problematic for critical applications.

Innovations and Advancements in Metal Powder Technology

Recent advancements in metal powder technology have addressed several of the challenges mentioned. Innovations in production techniques now allow for better control over particle size and shape, enhancing the uniformity of materials.

In addition, new sintering methods, including additive manufacturing techniques like 3D printing, are expanding the capabilities of metal powders. These technologies enable the creation of lightweight components with complex internal structures.

Research into recycling metal powders is also making strides, contributing to sustainability efforts in the industry. By reusing powders, manufacturers not only save costs but also reduce the environmental footprint associated with powder production.

Technological advancements continue to evolve, enhancing the roles metal powders play in modern manufacturing and providing solutions to existing challenges.

Conclusion

Metal powders play a crucial role in modern manufacturing, particularly in additive manufacturing and other advanced technologies. Their significance spans across various applications, influencing efficiency, cost-effectiveness, and material properties.

Recap of the Significance of Metal Powders

Metal powders are essential for producing complex components in sectors such as aerospace, automotive, and medical. Their characteristics directly affect the performance and quality of finished parts. Additive manufacturing techniques require metal powders with standardized properties to ensure consistency. For instance, the effective flowability and particle size distribution impact the precision of 3D printing. Additionally, the properties of metal powders influence the mechanical strength and thermal stability of the final products. These aspects reinforce the importance of rigorous testing and characterization methods in ensuring the reliability of metal powders in production processes.

Future Trends and Potential Developments in the Field

The metal powders industry is likely to witness significant innovations. Advances in powder metallurgy and recycling processes are expected to enhance the sustainability of metal powders. Creating more cost-effective methods for producing high-quality powders will be a priority. Technologies such as machine learning and AI are set to optimize the production and characterization of these materials. Moreover, developing new alloys and composite powders could broaden the scope of applications. Such innovations may also contribute to reducing the environmental impact of manufacturing processes, making metal powders more accessible and eco-friendly.

Final Thoughts on the Role of Metal Powders in Modern Manufacturing and Technology

Metal powders will continue to be at the forefront of advancements in manufacturing technology. Their versatility allows for tailoring material properties to meet specific engineering challenges. As industries evolve, the requirement for precise and durable materials will drive research into alternative powder compositions and processing methods. Continued investment in this field will enhance capabilities and foster innovations that drive efficiency and performance. The interaction between metal powders and modern manufacturing techniques positions them as a critical area of study for future developments.